Method for hollowing copper foil at position of differential pair via hole

A differential and copper foil technology, applied in the field of PCB design, can solve the problems of heavy copper foil workload, etc., and achieve the effect of reducing workload, wide application prospects, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

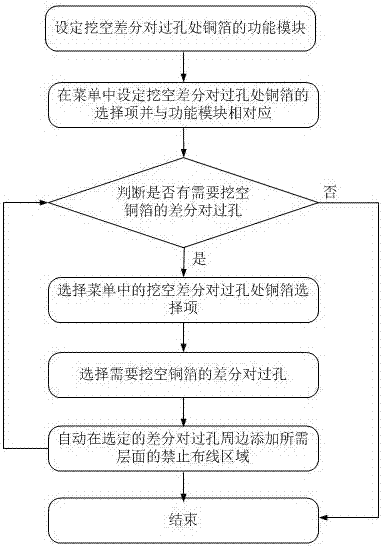

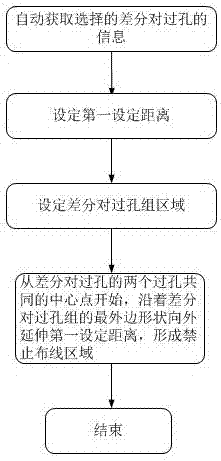

Method used

Image

Examples

Embodiment 1

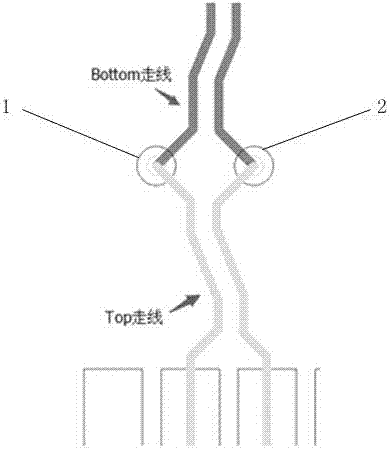

[0053] Example 1 image 3 As shown, it is necessary to hollow out the copper foil of the first differential pair positive signal via 1 and the first differential pair negative signal via 2 at the corresponding positions of the other PCB wiring layers outside the differential pair wiring layer;

[0054] Such as Figure 8 As shown, select the menu option "void for Diff via" to hollow out the copper foil at the differential pair via, click the differential pair via that needs to be hollowed out, and hollow out the first differential pair signal via 1 and No. A differential pair negative signal via 2 is a copper foil at the required level;

[0055] Automatically obtain the information of the differential pair via;

[0056] Automatically obtain the trace layer of the first differential pair positive signal via 1 and the first differential pair negative signal via 2, such as image 3 As shown, the positive signal of the first differential pair and the negative signal of the first differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com