Novel baby carrier circuit board

A new type of baby carriage and circuit board technology, applied in the field of baby carriages, can solve the problems of easy damage to electronic components of circuit boards, small space for circuit board installation, troublesome circuit board installation and operation, etc., and achieves good lighting effect, good heat dissipation effect, assembly and disassembly Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

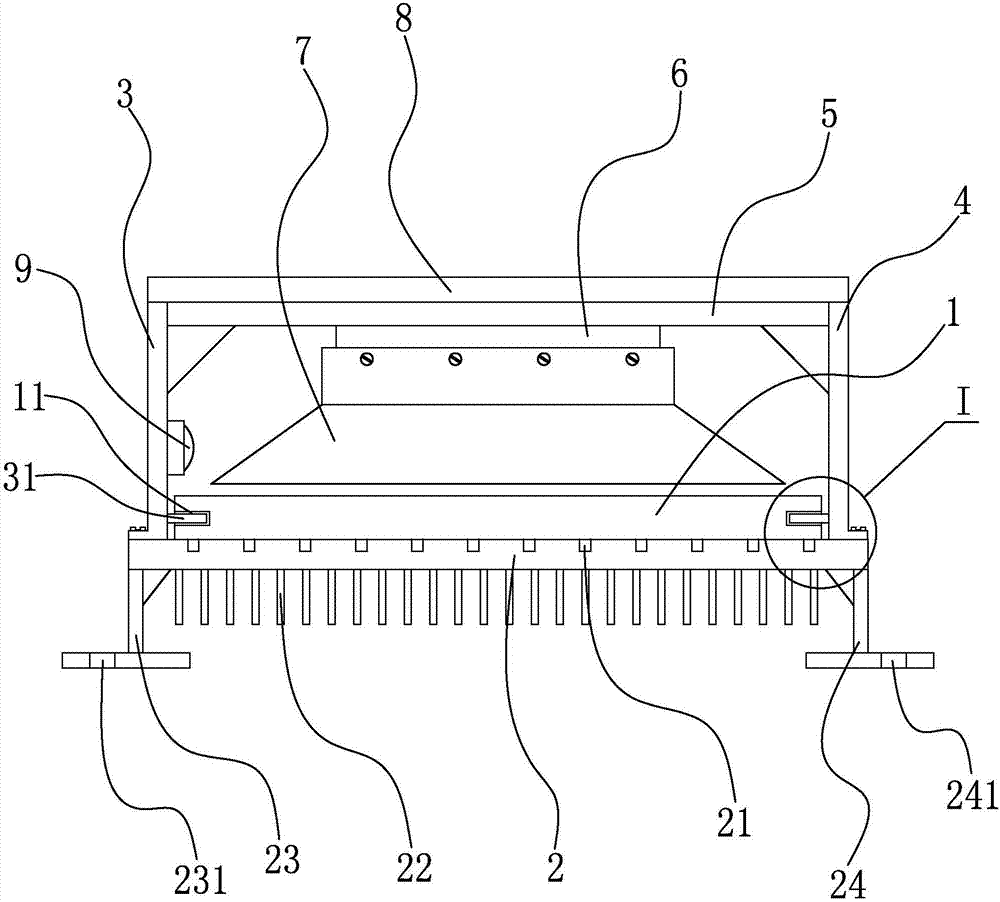

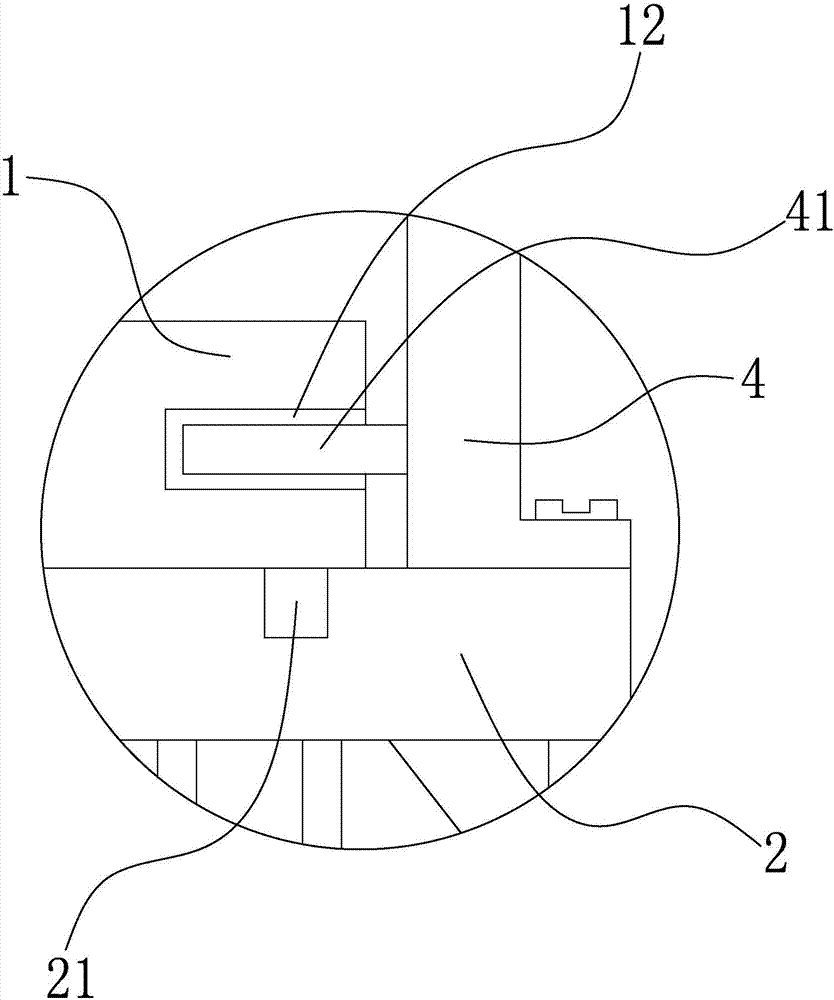

[0020] Example: such as figure 1 with figure 2 As shown, a new baby carriage circuit board includes a circuit board body 1, a heat dissipation plate 2 is fixedly bonded to the lower end surface of the circuit board body 1, and a plurality of heat dissipation grooves are arranged on the upper end surface of the heat dissipation plate 2. 21. The lower end surface of the heat dissipation plate 2 is integrally provided with a plurality of heat sinks 22; the left end of the heat dissipation plate 2 is integrally provided with several left support feet 23, and the right end of the heat dissipation plate 2 is integrally provided with several right support feet 24; The left end of the circuit board body 1 is detachably provided with a left vertical support plate 3, the right end of the circuit board body 1 is detachably provided with a right vertical support plate 4, and the upper ends of the left vertical support plate 3 and the right vertical support plate 4 are fixedly provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com