Cotton topping machine based on drone carrier

A technology of unmanned aerial vehicle and topping machine, which is applied to unmanned aerial vehicles, motor vehicles, botanical equipment and methods, etc., can solve the problems of inaccurate detection of the height of the top of cotton beads, and reduce the load and energy. The effect of consumption and efficient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

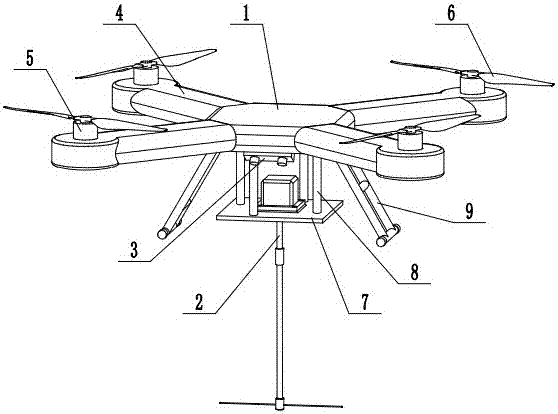

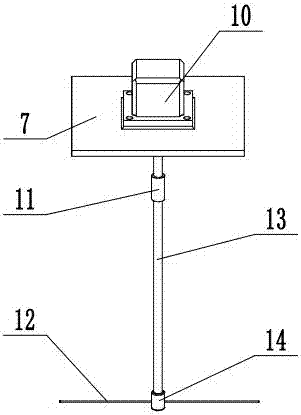

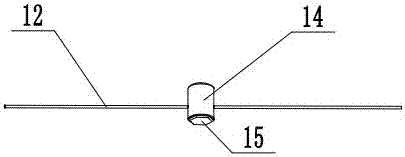

[0017] Embodiment 1: with reference to attached Figure 1~4 , the present invention includes a UAV body, a flight height control system, a topping power device, and a wire fixing device. The flight height control system is located inside the UAV body, and the topping power device is located below the UAV body and fixed on a fixed On the plate 7, the steel wire fixing device is located below the topping power device and is connected to the connecting shaft 13; Drop frame 9, above-mentioned four wings 4 are fixed on the four directions of main body 1, four driving motors 5 are respectively fixed on the ends of wing 4, and four propellers 6 are respectively arranged on the motor shaft of driving motor 5, and above-mentioned four A strut 8 is fixed below the main body 1, one end is connected with the main body 1, and the other end is connected with the fixed plate 7, the above-mentioned landing gear 9 is arranged under the two sides of the main body 1, and is respectively located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com