Flexible fixture device for machining aviation complex thin-walled parts and fabrication method of flexible fixture device

A technology of flexible fixtures and fixture devices, applied in the field of processing and manufacturing, can solve problems such as inability to meet assembly requirements, and achieve the effects of simple structure, convenient operation, high interchangeability and modularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

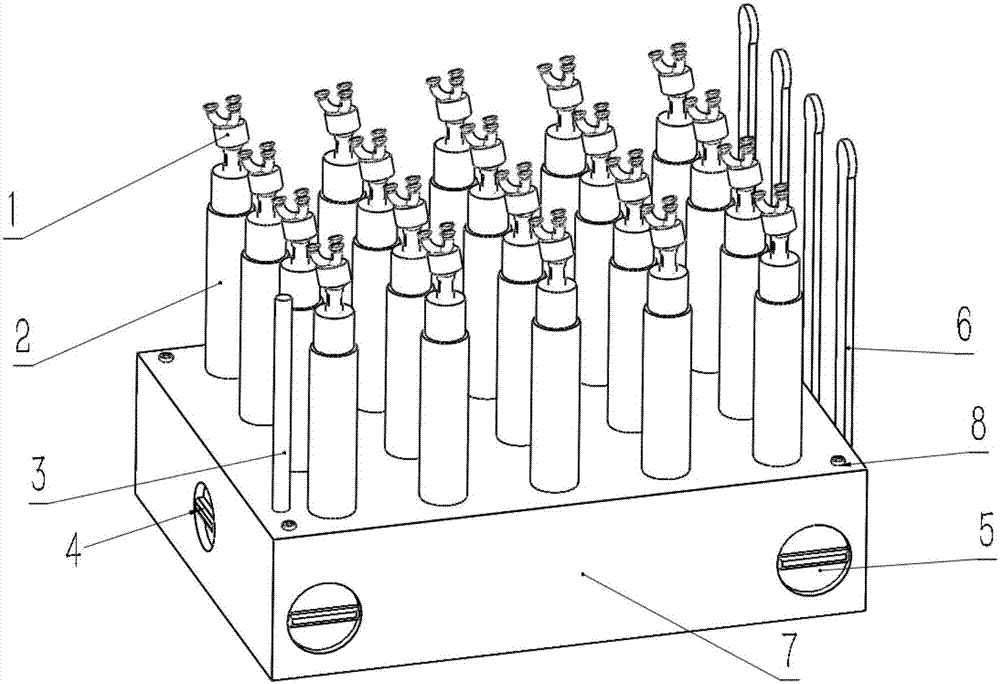

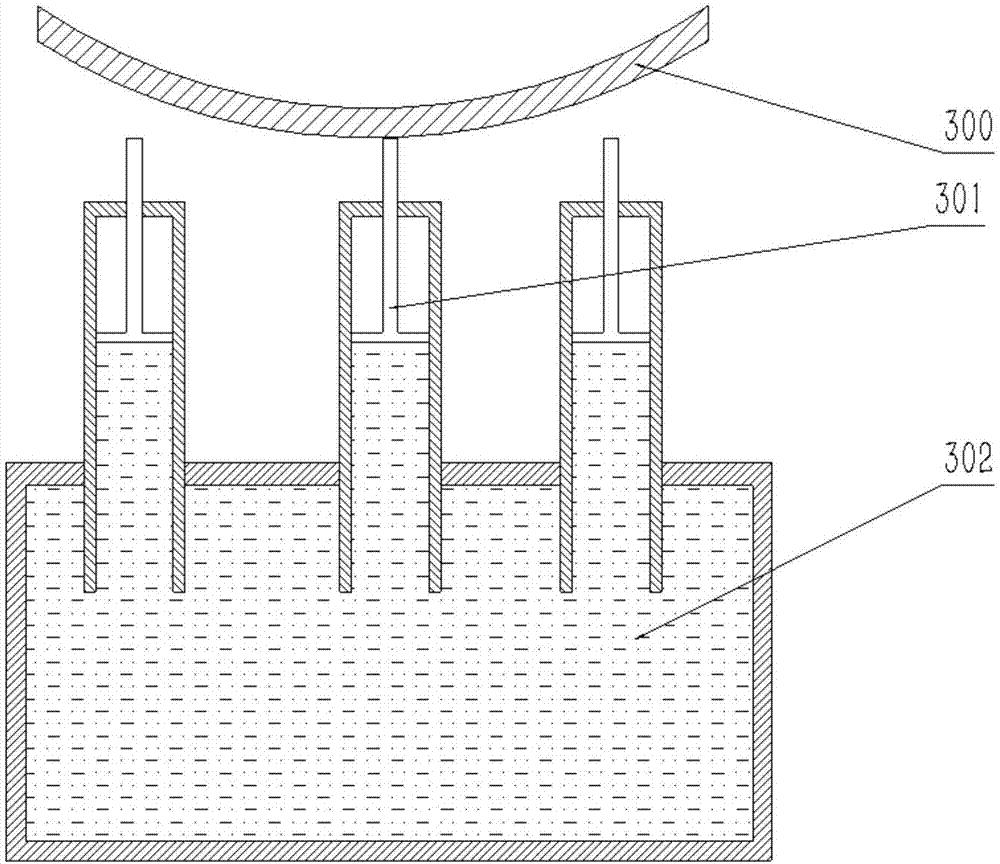

[0027] In the drawings: 1--Universal head; 2--Piston; 3--Auxiliary support rod; 4--Electromagnetic locking device; 5--Manual electromagnet; 6--Detection device; 7--Clamp box; 8--Machining reference zero mark; image 3 Middle 300--thin-walled workpiece; 301--piston rod; 302--liquid; 400--solenoid valve in Figure 4; 401--valve body; 402--connecting rod in X direction; 403--connecting rod in Y direction; 404—overflow hole; A, B, and C are three selected detection points in Fig. 5, a, b, and c are each point in the detection device 6, and L1, L2, and L3 are obtained after measurement and processing The relative height of each point.

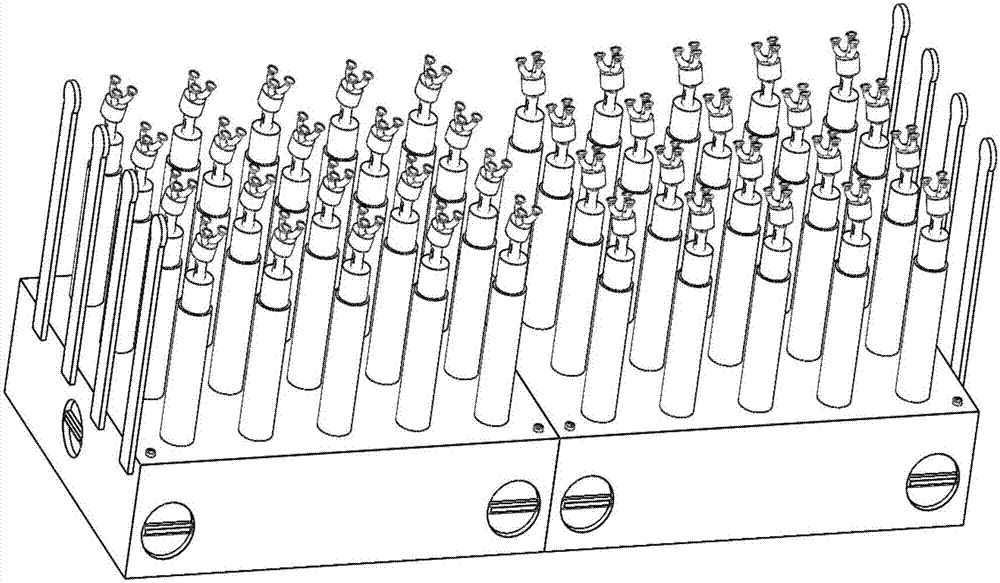

[0028] The present invention is a kind of flexible fixture device for processing aviation complex thin-walled parts, such as figure 1 As shown, the flexible fixture device consists of 2 flexible fixture modules.

[0029] A single flexible fixture module such as figure 2 As shown, three small rubber suction cups are fixed on the upper end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com