Interactive lifting formwork device and construction method

A technology of lifting rods and lifting units, which is applied in the field of interactive lifting formwork devices, can solve the problems of high labor intensity, poor quality perception, and large investment in turnover materials, so as to reduce labor intensity, excellent quality perception, and high modularization degree Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

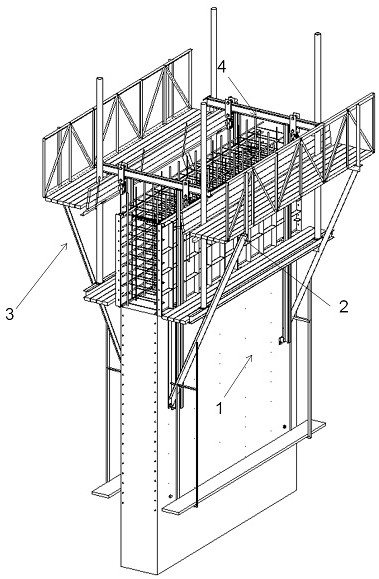

[0046] Embodiment one: by Figure 1 to Figure 11 Given, an interactive lifting formwork device, including an attachment unit 1, a formwork unit 2, a triangular truss operating platform unit 3 and a lifting unit 4, such as figure 1 shown;

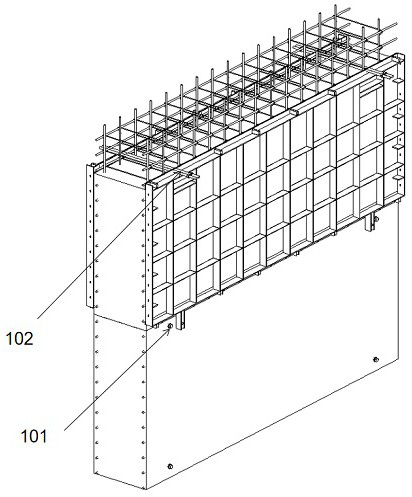

[0047] The attachment unit 1 includes a climbing cone 101 and a pair of drawing rods 102, such as figure 2 shown;

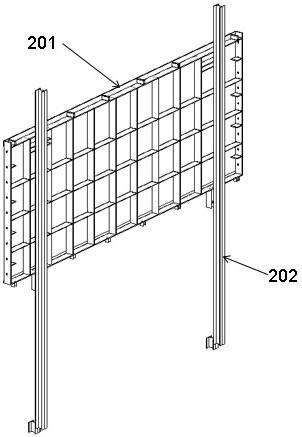

[0048] The template unit 2 includes a template 201 and a platform lifting rod 202, and the platform lifting rod 202 is attached to the template 201, such as image 3 shown;

[0049] The triangular truss operating platform unit 3 (see Figure 4 and Figure 5 ) includes a lower operating platform, a middle operating platform and an upper operating platform, the lower operating platform includes a hanger 301 and a lower aisle plate 302, the middle operating platform includes a middle tripod structure 303 and a middle aisle plate 304, the upper operating platform The platform includes an upper tripod structure 305, an upper ...

Embodiment 2

[0056] Embodiment 2: An interactive lifting construction method:

[0057] S1: Carry out the construction of the first plate tube wall (see Figure 8 ): first set up the inner and outer fastener type steel pipe scaffolding as the operating frame (5), bind the first steel frame (6) and pre-bury the climbing cone 101 in the first steel frame (6), and then hang the formwork (201) and the filling formwork (9) at the bottom, set the leveling steel pipe (7) through the operation frame (5), and support and level the formwork 201 through the leveling steel pipe (7), and further use the climbing cone bracket (8), to The drawing rod (102) fixes the template 201 and the supplementary template (9), and then pours the first slab of concrete;

[0058] S2: After the first slab of concrete reaches the design strength, remove the formwork (201), bind the steel skeleton of the second slab, remove the operating frame (5), and install and fix the triangular truss inside and outside the first slab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com