Rosewood dehumidifying process based on inhibition of cell activity

A technology for inhibiting cells and mahogany, applied in the manufacture of tools, wood processing equipment, impregnated wood, etc., can solve the problems of long drying time, shortening the drying time of mahogany, and the difficulty of drying in the drying process, and achieve the effect of reducing expansion and contraction movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

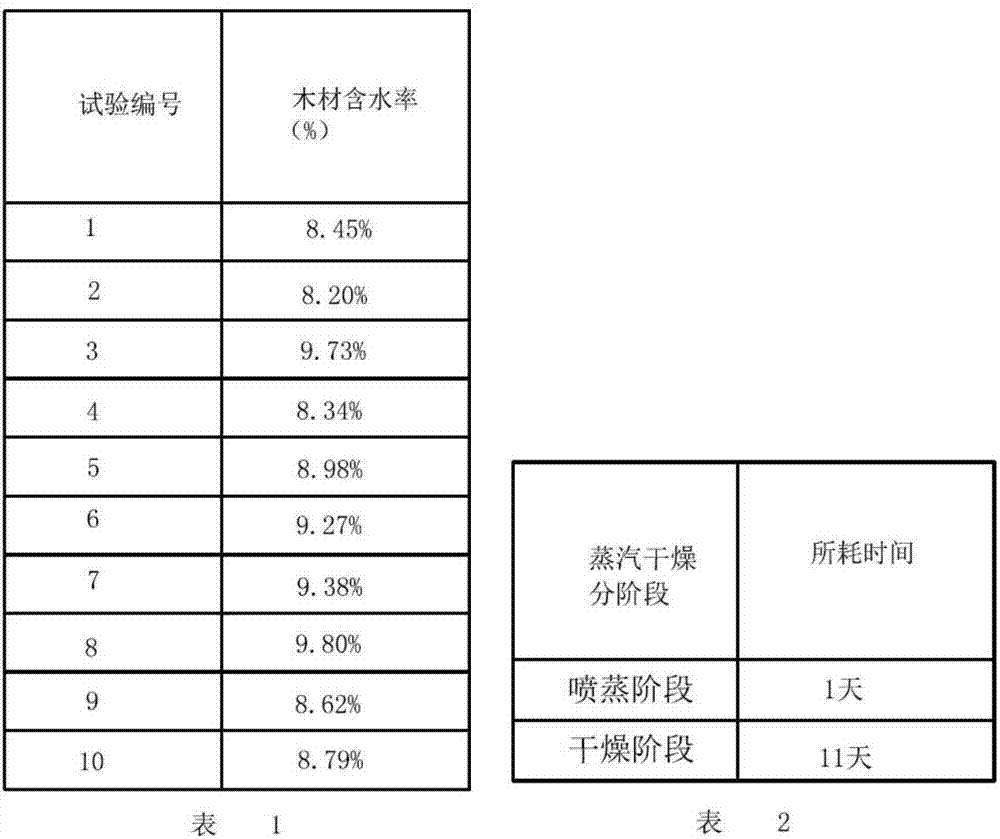

[0028] The current steam drying in wood drying was used as a comparison, and the test objects were 10 purple elms purchased from Guangdong.

[0029] Steam drying includes spray steaming stage (preheating), drying stage, and humidity control stage (drying follow-up adjustment stage, not for comparison), and the time spent in spray steaming stage and drying stage is mainly compared.

[0030] As shown in Table 1 and Table 2.

[0031]

[0032] As shown in Table 1 and Table 2, the moisture content of wood obtained from 10 purple elms by the steam drying method is 8.2%-9.8%, and the time spent is 12 days (excluding the humidity-conditioning stage).

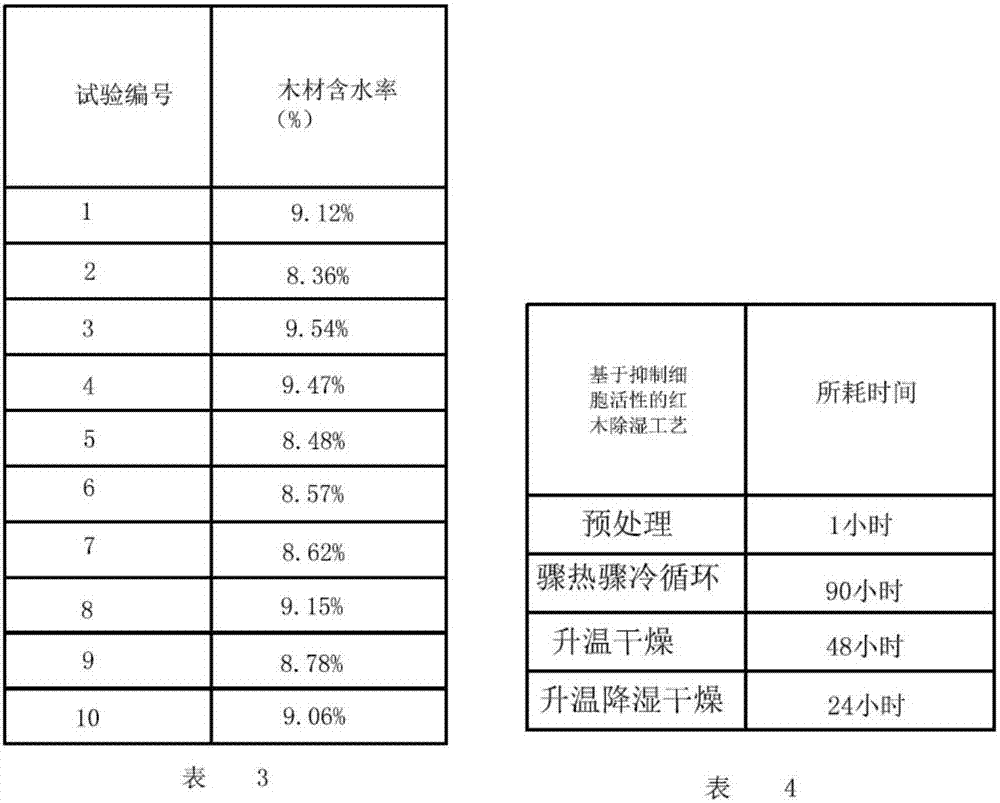

[0033] The test object of this mahogany dehumidification process based on the inhibition of cell activity is also 10 purple elms purchased from Guangdong, including the following steps:

[0034] a, pretreatment, remove the branches and leaves of the felled mahogany, and then rinse the mahogany surface with a high-pressure water gun ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com