Silica gel inner lining teflon flexible pipe and manufacturing technology thereof

A production process, Teflon technology, applied in the direction of hoses, pipes, tubular objects, etc., can solve problems such as damage, thick hose thickness, cracking, etc., to improve toughness and strength, not easy to bend and rupture, and the effect is remarkable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with accompanying drawings and specific preferred embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. range is limited.

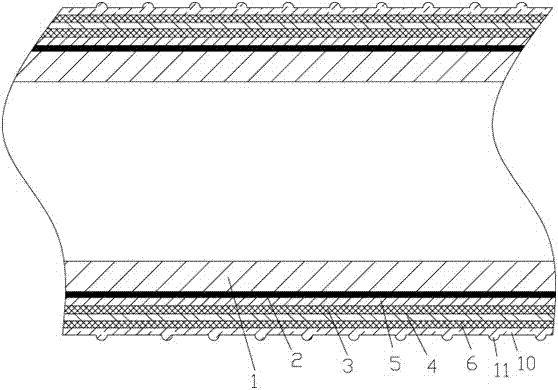

[0022] Examples, see e.g. figure 1 Shown, a kind of silica gel lining Teflon hose, comprises Teflon casing 1, is coated with coupling agent layer 2 on the outer wall of described Teflon casing 1, on the outer wall of coupling agent layer 2 A silica gel layer 5 is fixed, and a PET outer tube 10 is fixed on the outer wall of the silica gel layer 5, and the first adhesive plaster layer 3, the stainless steel wire layer 4 and the second adhesive plaster layer 6 are compounded in the PET outer tube 10, and the first adhesive plaster layer 6 of the PET outer tube 10 is A tape layer 3 is wound on the outer wall of the silica gel layer 5 , a stainless steel wire layer 4 is wound on the outer wall of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com