Efficient making method for packaging boxes

A production method and packaging box technology, applied in the field of packaging boxes, can solve problems such as difficulty in meeting high-efficiency requirements, slowing down efficiency, and small mechanical processing procedures, saving pre-processing time, reducing time and procedures, and preventing products. unqualified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

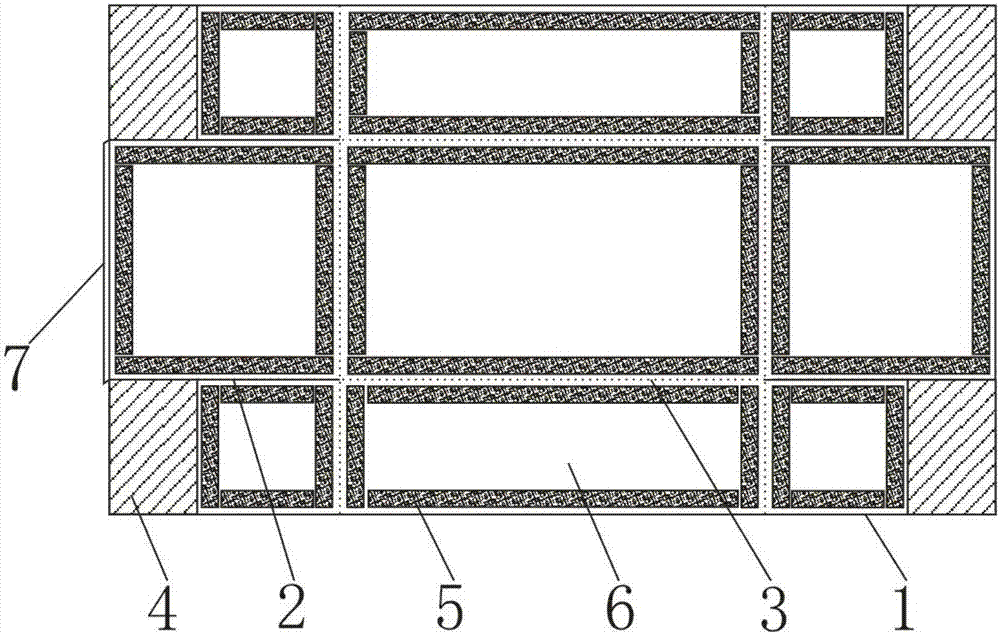

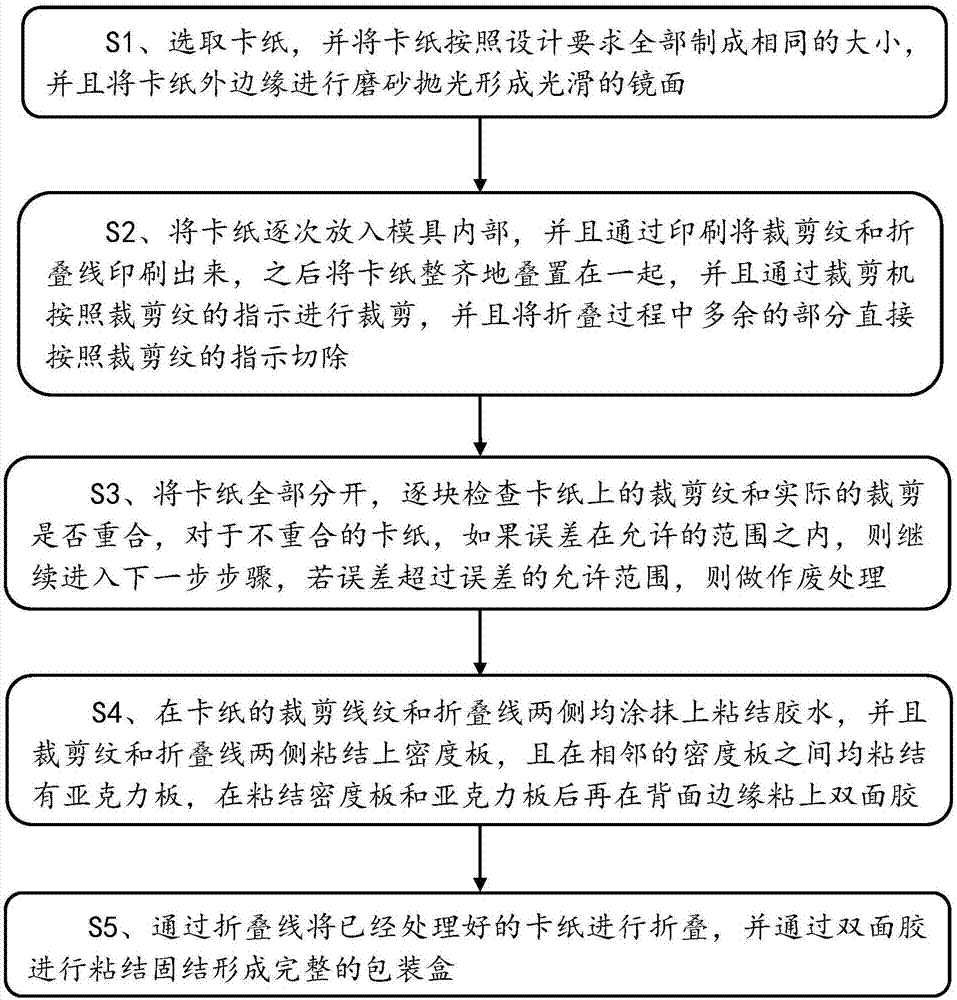

[0023] like figure 1 and figure 2 Shown, a kind of high-efficiency manufacturing method of packing box comprises the following steps:

[0024] S1. Select the cardboard, and make all the cardboards into the same size according to the design requirements, and grind and polish the outer edge of the cardboard to form a smooth mirror surface. You can also paste colored decorative paper on the edge of the polished cardboard. After the cardboard is made into the same size, the unified follow-up operation can be carried out, and the marking and cutting can be realized in one operation, which improves the efficiency in the actual production process;

[0025] S2. Put the cardboard into the mold one by one, and print the cutting pattern and folding line through printing, and then stack the cardboard neatly together. The purpose of making the cutting pattern and folding line through printing is to facilitate the inspection in the subsequent steps , and can be conveniently folded or tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com