Bonding method and bonding structure of semiconductor material

A bonding structure and semiconductor technology, applied in the direction of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as product failure, affecting device performance, and high heat treatment temperature requirements, so as to improve product reliability and ensure device performance, the effect of reducing bonding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

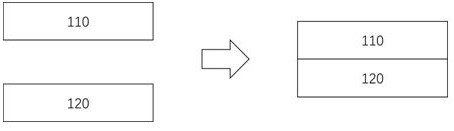

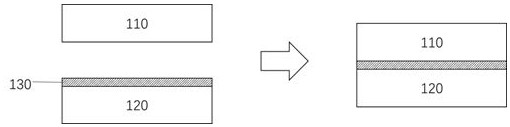

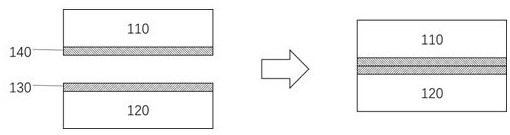

[0041] In order to solve the above-mentioned problems in the prior art, the present invention provides a bonding method and a bonding structure for semiconductor materials. By forming a mixed surface of a semiconductor medium and an insulating medium on at least one piece of semiconductor material, the bonding interface includes both semiconductor materials. The contact area between the medium and the semiconductor medium also includes the contact area between the semiconductor medium and the insulating medium and / or the contact area between the insulating medium and the insulating medium. The contact area between the semiconductor medium and the semiconductor medium is used for charge transfer to avoid problems such as arcing effect, product failure, and machine pollution caused by charge accumulation; the contact area between the semiconductor medium and the insulating medium and / or the contact area between the insulating medium and the insulating medium is used for It can ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com