A kind of titanium base amorphous fiber and preparation method thereof

An amorphous and fibrous technology, applied in the field of titanium-based amorphous fibers and their preparation, can solve the problems of inability to make Ti-based fibers, and achieve the effects of good mechanical properties, good thermal stability, and avoiding direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

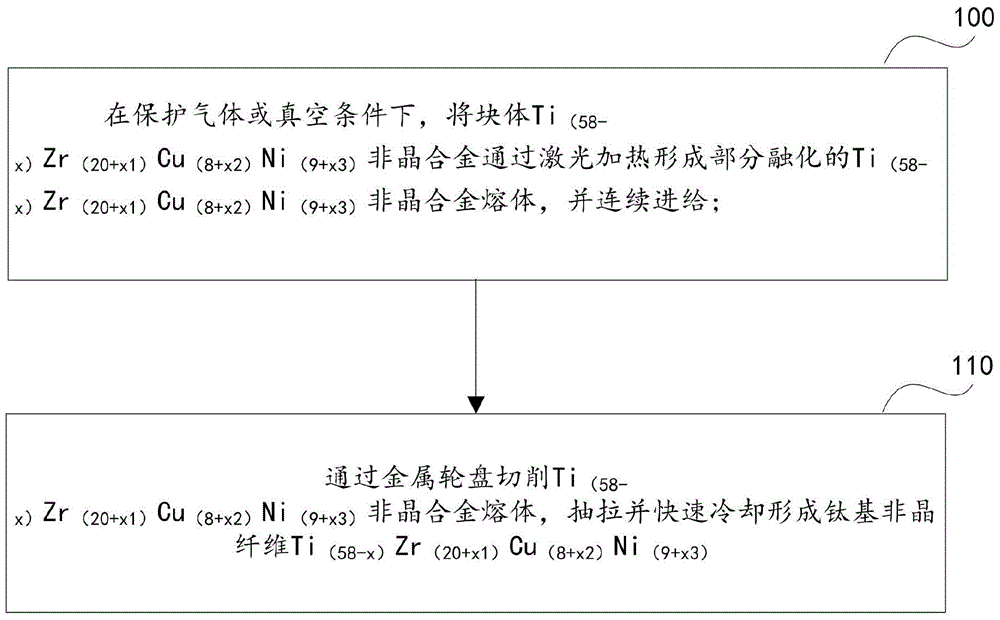

[0020] refer to figure 1 As shown, the preparation method of the above-mentioned titanium-based amorphous fiber provided in the embodiment of the present invention specifically includes the following steps:

[0021] Step 110: under protective gas or vacuum conditions, the bulk Ti (58-x) Zr (20+x1) Cu (8+x2) Ni (9+x3) Alloy is heated by laser to form partially melted Ti (58-x) Zr (20+x1) Cu (8+x2) Ni (9+x3) Alloy melt, and continuous feeding.

[0022] Specifically, under protective gas or vacuum conditions, the continuously fed bulk Ti (58-x) Zr (20+x1) Cu (8+x2) Ni (9+x3) Alloy is heated by laser to form partially melted Ti (58-x) Zr (20+x1) Cu (8+x2) Ni (9+x3) Before alloying the melt, also include steps:

[0023] The mixing is carried out according to the atomic percentage of 58-x for the simple substance of Ti, 20+x1 for the simple substance of Zr, 8+x2 for the simple substance of Cu and 9+x3 for the simple substance of Ni.

[0024] The mixture obtained aft...

Embodiment 1

[0032] Example 1, (1) Configure elemental Ti, Zr, Ni, and Cu as Ti according to the ratio of setting the atomic percentage to 58, 25, 8, and 9 58 Zr 25 Cu 8 Ni 9 Alloy, and in the magnetron tungsten arc melting furnace suction casting forms alloy rod-shaped material, in this embodiment 1 Ti 58 Zr 25 Cu 8 Ni 9 Alloys are called master alloys. (2) Cut the prepared master alloy rods into 3-7cm long columns by wire electric discharge cutting, polish them with sandpaper, clean them with ultrasonic waves, dry them, and place them in the crucible of the melt drawing equipment. (3) Vacuum the melt drawing device to 10 -3 Pa, fill in high-purity argon until the air pressure in the melt drawing device is -0.5MPa; continue to evacuate the air pressure in the melt drawing device to 10 -3 Pa, filled with high-purity argon. (4) Set the rotational speed of the copper wheel to 2800r / min, and the feeding speed of the master alloy to 5mm / min. (5) The metal roller is copper alloy, star...

Embodiment 2

[0034] Example 2, (1) According to the ratio of setting the atomic percentage to 50, 30, 10, 10, the elemental Ti, Zr, Ni, and Cu are configured as Ti 50 Zr 30 Cu 10 Ni 10 Amorphous alloy, and in magnetron tungsten electric arc melting furnace suction casting forms alloy rod-shaped material, in this embodiment 2 Ti 50 Zr 30 Cu 10 Ni 10 Amorphous alloys are called master alloys. (2) Cut the prepared master alloy rods into 3-7cm long columns by wire electric discharge cutting, polish them with sandpaper, clean them with ultrasonic waves, dry them, and place them in the crucible of the melt drawing equipment. (3) Vacuum the melt drawing device to 10 -3 Pa, fill in high-purity argon until the air pressure in the melt drawing device is -0.5MPa; continue to evacuate the air pressure in the melt drawing device to 10 -3 Pa, filled with high-purity argon. (4) Set the rotational speed of the copper wheel to 3000r / min, and the feeding speed of the master alloy to 7mm / min. (5) T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com