A kind of semiconductor device and its manufacturing method

A manufacturing method, semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., to avoid sticking and product failure problems, and avoid electrostatic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

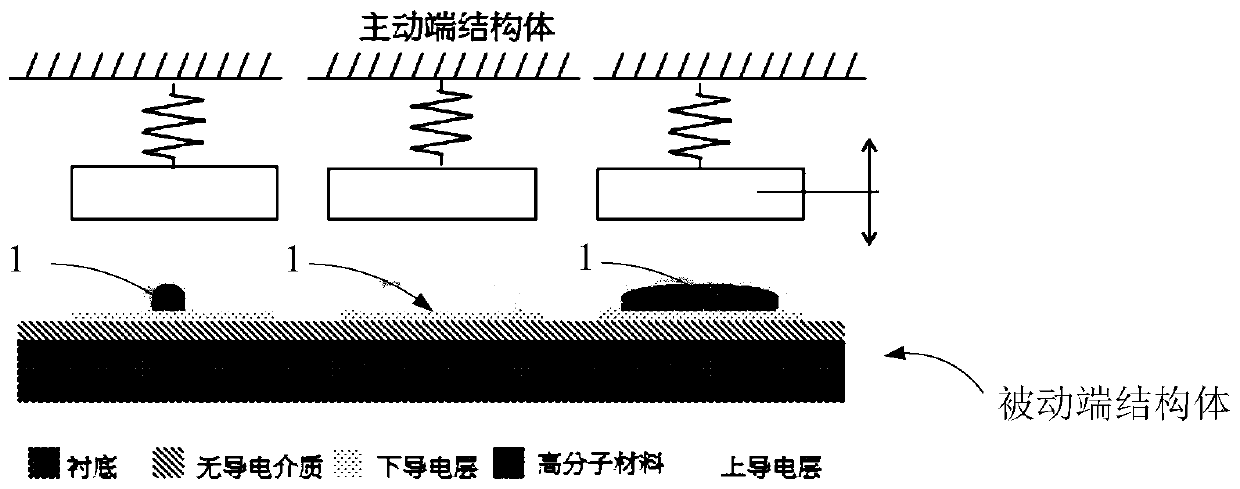

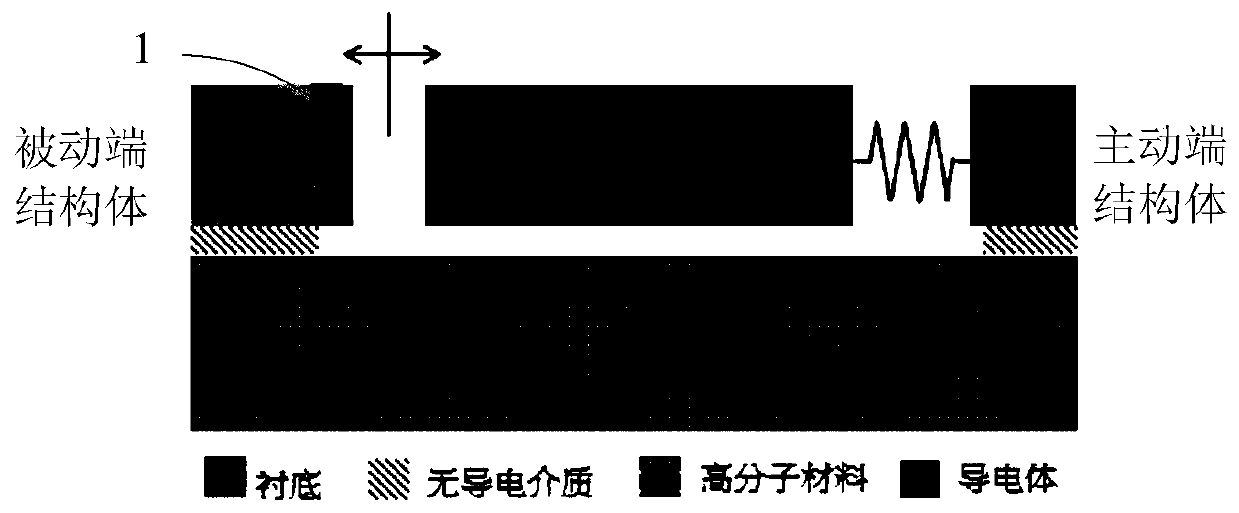

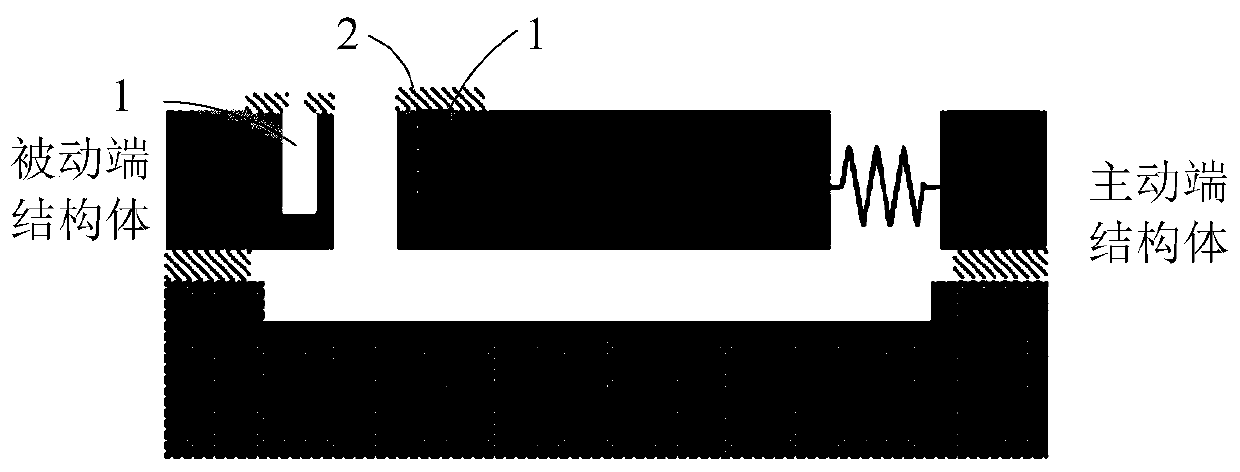

[0063] Embodiment 1 of the present application provides a semiconductor device, figure 1 is a schematic diagram of the semiconductor device of this embodiment.

[0064] Such as figure 1 As shown, the semiconductor device may have an active end structure and a passive end structure, and the active end structure and the passive end structure can move relative to each other and contact each other.

[0065] In this example, if figure 1 As shown, at least one of the active end structure and the passive end structure has a cavity 1, and the cavity is formed as an accommodating space. The cavity can be surrounded by a bottom and an outer wall, and both the outer wall and the bottom are conductive. material, wherein the outer wall is the upper conductive layer in the figure, and the bottom is the lower conductive layer in the figure. Wherein, the outer wall protrudes in the direction of relative movement relative to the bottom, and the part where the active end structure and the pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com