Wood-based three-dimensional hollow composite plate

A composite sheet and composite material layer technology, which is applied in the direction of synthetic resin layered products, building components, layered products, etc., can solve the problems of matching functionality and structural strength, and achieve excellent vibration absorption, strong designability, and production The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

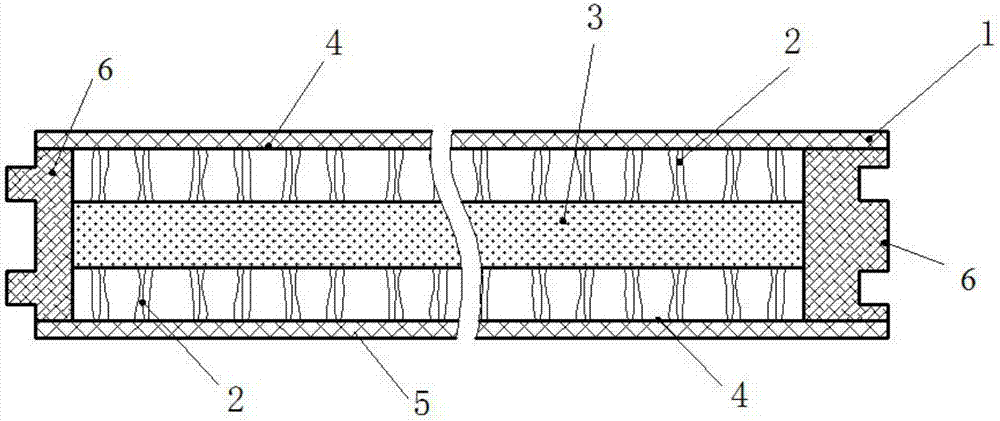

[0016] A wood-based three-dimensional hollow composite board, comprising an upper panel 1 and a lower panel 5, a foam layer 3 is arranged between the upper panel 1 and the lower panel 5, and a 3D hollow fabric reinforced composite material is arranged between the upper panel 1 and the foam layer 3 Layer 2, 3D hollow fabric reinforced composite material layer 2 is arranged between lower panel 5 and foam layer 3, between upper panel 1 and 3D hollow fabric reinforced composite material layer 2, 3D hollow fabric reinforced composite material layer 2 and foam layer 3 Adhesive layers 4 are provided between the lower panel 5 and the 3D hollow fabric reinforced composite material layer 2 .

[0017] The height of the 3D hollow fabric reinforced composite material layer 2 is less than 1 / 2 of the height of the foam layer 3 .

[0018] Both the upper panel 1 and the lower panel 5 are made of high-density recombined wood or density board or solid wood or wood-plastic or resin-based composit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com