A kind of resin decorative board and preparation method thereof

A decorative board and resin technology, applied in the field of interior decoration, can solve the problems of not being able to meet the diverse needs of customers, affecting the structure and molding of decorative boards, and easy displacement or deformation of decorative materials, so as to achieve protection against breakage and improve beautification Function, improve the effect of three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

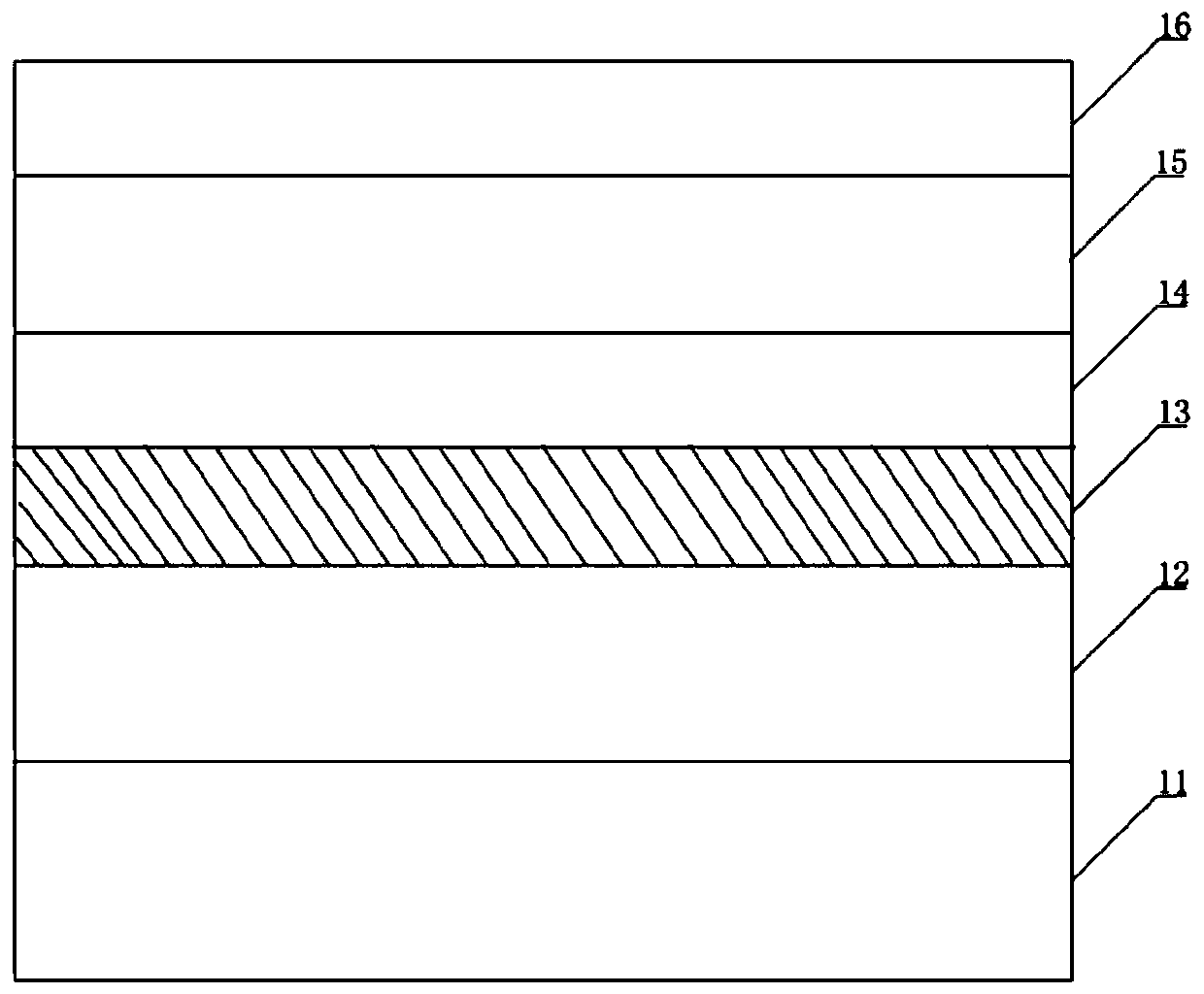

[0047] A resin decorative board, comprising a 5mm thick first glass layer, the surface of the first glass layer is sequentially provided with a 3mm thick first resin decorative layer, a 2mm thick decorative material layer, and a 1mm thick light-transmitting layer from the inside to the outside. Resin cured layer, a 3mm thick second glass layer and a 1mm thick second resin decorative layer; the first resin decorative layer and the second resin decorative layer include stone powder, aluminum powder, unsaturated polyester resin, and the light-transmitting The cured resin layer is transparent unsaturated polyester resin, and the decorative material layer includes stones and shells.

[0048] The preparation method of resin decorative board comprises the following steps:

[0049] 1) Put the first glass layer into the cooling pool desktop;

[0050] 2) Add stone powder, aluminum powder, unsaturated polyester resin, curing agent and adhesive to the rotary machine, set the rotation spe...

Embodiment 2

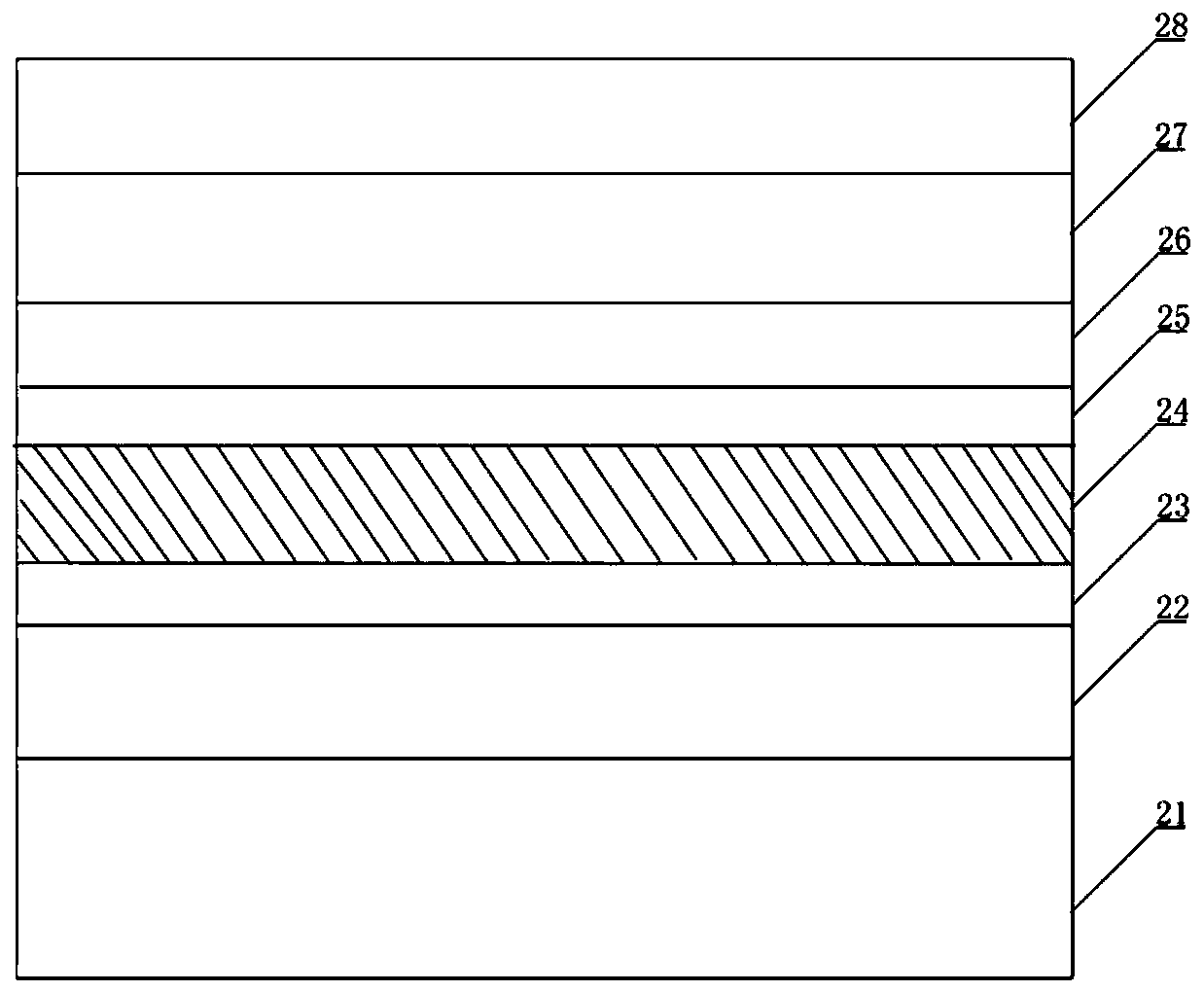

[0057] A resin decorative board, comprising a 3mm thick first glass layer, the surface of the first glass layer is sequentially provided with a 2mm thick first resin decorative layer, a 1mm thick first transparent film layer, a 2mm thick Decorative material layer, 1mm thick second transparent film layer, 1mm thick light-transmitting resin cured layer, 5mm thick second glass layer and 3mm thick second resin decorative layer; the first resin decorative layer and the second resin The decoration layer includes stone powder, aluminum powder, transparent epoxy resin and pigments, the light-transmitting resin cured layer is transparent epoxy resin, and the decoration material layer includes stone and wood.

[0058] The preparation method of resin decorative board comprises the following steps:

[0059] 1) Put the first glass layer into the cooling pool desktop;

[0060] 2) Add stone powder, aluminum powder, transparent epoxy resin, pigment, curing agent and adhesive to the rotary ma...

Embodiment 3

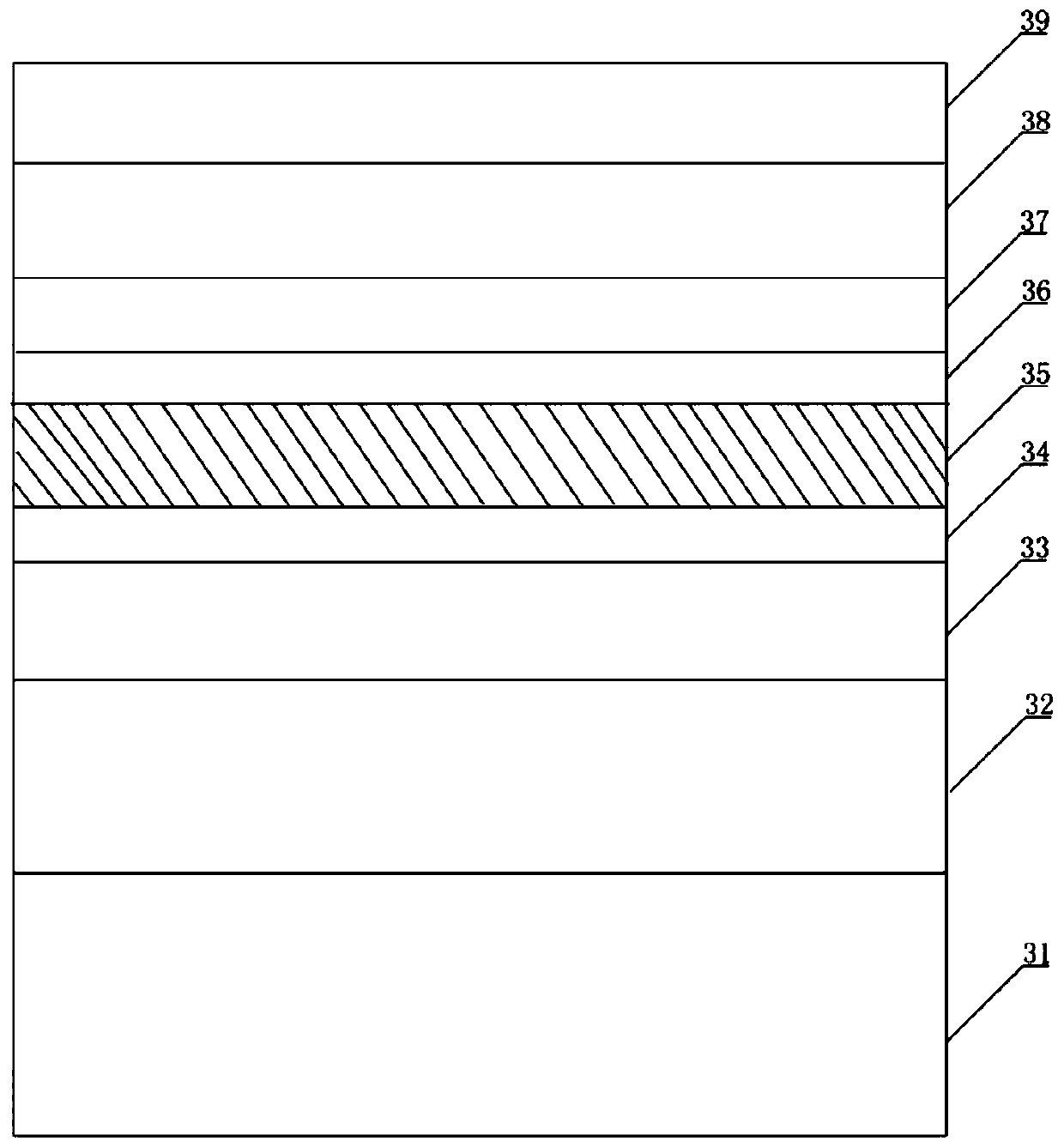

[0069] A resin decorative board, comprising a 0.5cm thick wood layer, the surface of the wood layer is sequentially provided with a 6mm thick first glass layer, a 4mm thick first resin decorative layer, and a 1mm thick first transparent film from the inside to the outside layer, a 2mm thick decorative material layer, a 1mm thick second transparent film layer, a 1mm thick light-transmitting resin cured layer, a 6mm thick second glass layer and a 2mm thick second resin decorative layer; the first resin decoration The layer and the second resin decoration layer include stone powder, aluminum powder, unsaturated polyester resin, pigment and pearl powder, the light-transmitting resin solidified layer is transparent unsaturated polyester resin, and the decorative material layer is animal and plant specimens.

[0070] The preparation method of resin decorative board comprises the following steps:

[0071] 1) Put the plank layer into the cooling pool desktop;

[0072] 2) Lay the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com