Plastic deformation measuring system and method for austenitic stainless steel stamped seal head

A technology of austenitic stainless steel and plastic deformation, which is applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of easy loss of marks and easy damage to the surface of the head, and achieve low cost, enhanced traceability, The effect of reducing human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

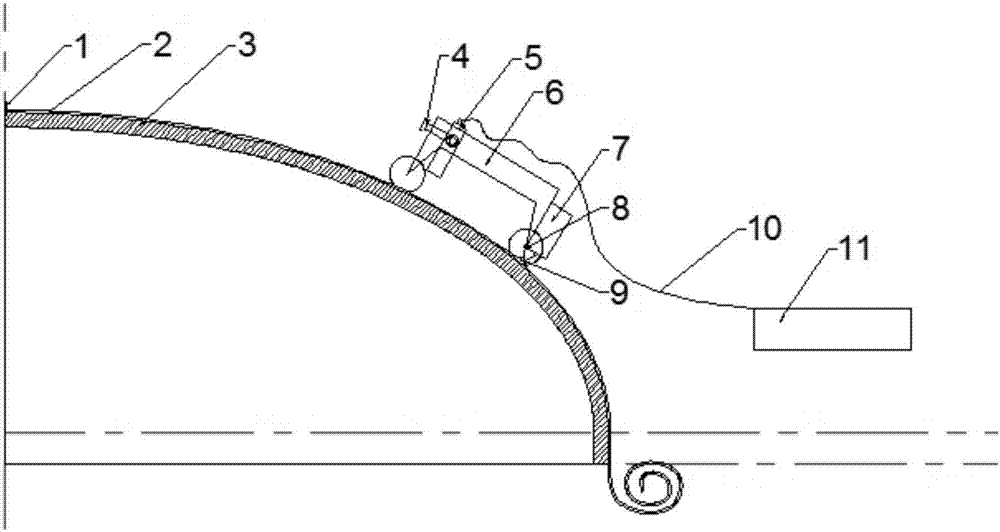

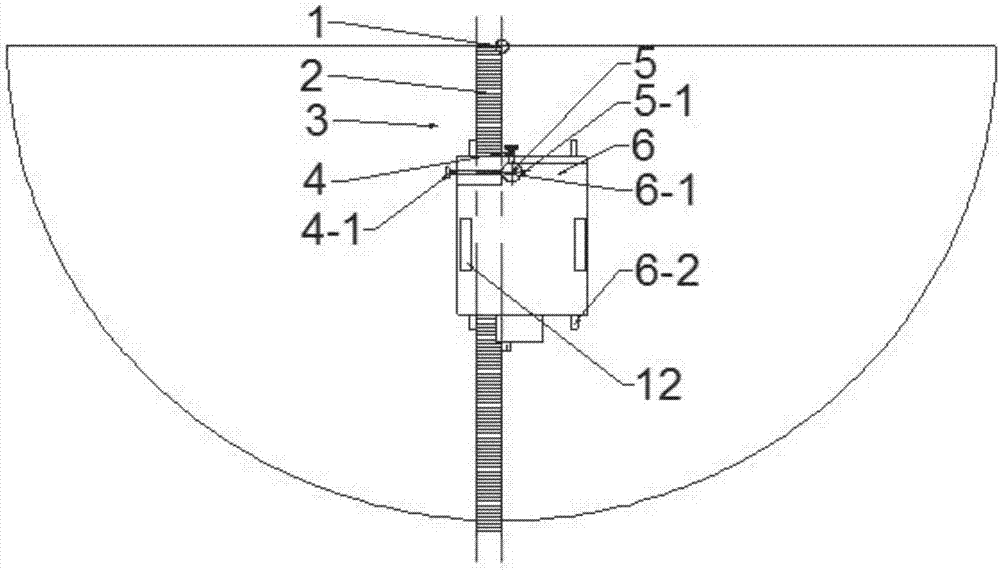

[0039]Aiming at the actual demand for measuring the plastic deformation of the austenitic stainless steel stamped and formed head, the present invention provides a system and method for measuring the plastic deformation of the austenitic stainless steel stamped and formed head, and realizes that the austenitic stainless steel head is stamped and formed High-efficiency, high-precision and non-destructive measurement of plastic deformation. The measurement system and method are suitable for measuring the plastic deformation of the outer surface of a convex head with a diameter not exceeding 5000mm.

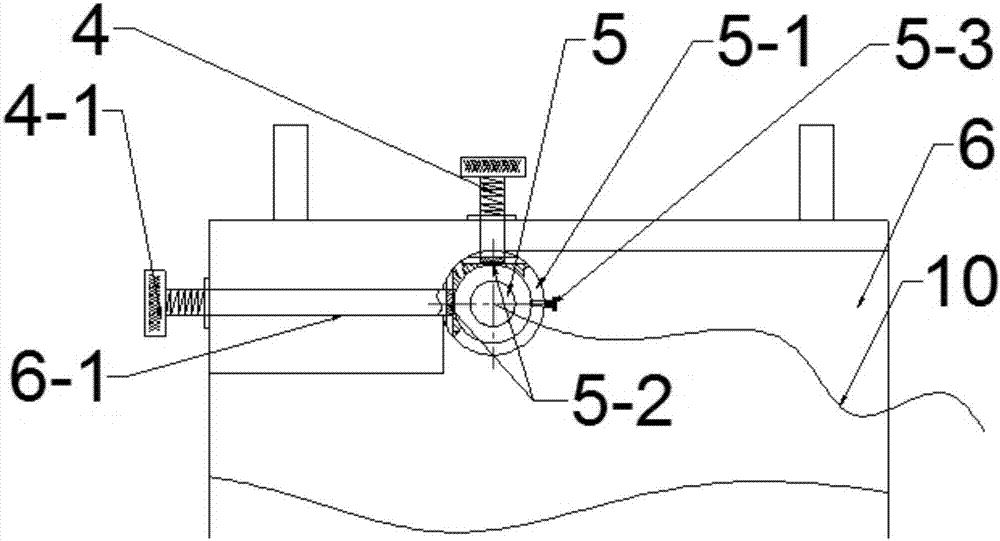

[0040] The plastic deformation measurement system of austenitic stainless steel stamped and formed heads includes a marker 1 located at the apex of the head, a guide tape 2 and a moving marking device; the moving marking device includes a measuring platform 6 with four guide wheels 6 at the bottom -2,), used for the support and quick guide positioning of the measuring platform 6. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com