Determination method for expansion degree of dry briquette

A measurement method and technology of expansion degree, which is applied in the field of coking coal, can solve problems such as the size of briquettes is too large and the inability to measure the expansion degree of Oya

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

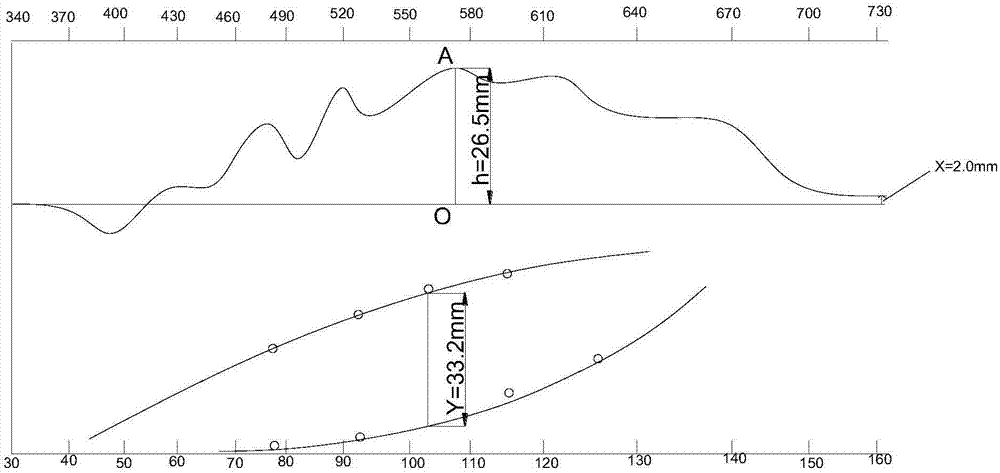

[0028] This embodiment discloses a method for measuring the swelling degree of dry briquettes, comprising the following steps:

[0029] 1) Get 50g dry coal powder and 50g crushed briquette and mix evenly, wherein, the average particle size of dry coal powder is controlled at about 0.4mm, and the particle size of briquette is controlled at about 10mm, and the briquette after described dry coal powder and crushing The coal is fat coal; put it into the coal cup;

[0030] 2) Put the coal cup in the brick coal hole of the electric furnace, install the colloid body volume curve recording paper on the drum, and display the colloid body volume curve on the computer terminal in real time through the computer, and start the electric furnace to start heating;

[0031] 3) Referring to GB / T479-2000 Determination Method of Bituminous Coal Colloidal Layer Index, draw the colloidal body volume curve, and measure the maximum thickness Y value and shrinkage X value of the colloidal layer of dry...

Embodiment 2

[0035] This embodiment discloses a method for measuring the swelling degree of dry briquettes, comprising the following steps:

[0036] 1) Get 40g of dry coal powder and 60g of crushed briquettes and mix evenly, wherein, the average particle size of dry coal powder is controlled at about 0.35mm, and the particle size of briquette is controlled at about 10mm. All the coals are gas-rich coal; put them into the coal cup;

[0037] 2) Put the coal cup in the brick coal hole of the electric furnace, install the colloid body volume curve recording paper on the drum, and display the colloid body volume curve on the computer terminal in real time through the computer, and start the electric furnace to start heating;

[0038] 3) Referring to GB / T479-2000 Determination Method of Bituminous Coal Colloidal Layer Index, draw the colloidal body volume curve, and measure the maximum thickness Y value and shrinkage X value of the colloidal layer of dry briquettes, and wait for the temperature ...

Embodiment 3

[0042] This embodiment discloses a method for measuring the swelling degree of dry briquettes, comprising the following steps:

[0043] 1) Mix 60g of dry coal powder with 40g of crushed briquettes evenly, wherein the average particle size of dry coal powder is controlled at about 0.32mm, and the particle size of briquette is controlled at about 5mm. The coal is gas coal; put it into the coal cup;

[0044] 2) Put the coal cup in the brick coal hole of the electric furnace, install the colloid body volume curve recording paper on the drum, and display the colloid body volume curve on the computer terminal in real time through the computer, and start the electric furnace to start heating;

[0045] 3) Referring to GB / T479-2000 Determination Method of Bituminous Coal Colloidal Layer Index, draw the colloidal body volume curve, and measure the maximum thickness Y value and shrinkage X value of the colloidal layer of dry briquettes, and wait for the temperature of the electric furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com