Turning machining parameter optimization method considering uncertain parameters,

A technology of processing parameters and optimization methods, applied in the fields of electrical digital data processing, design optimization/simulation, special data processing applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

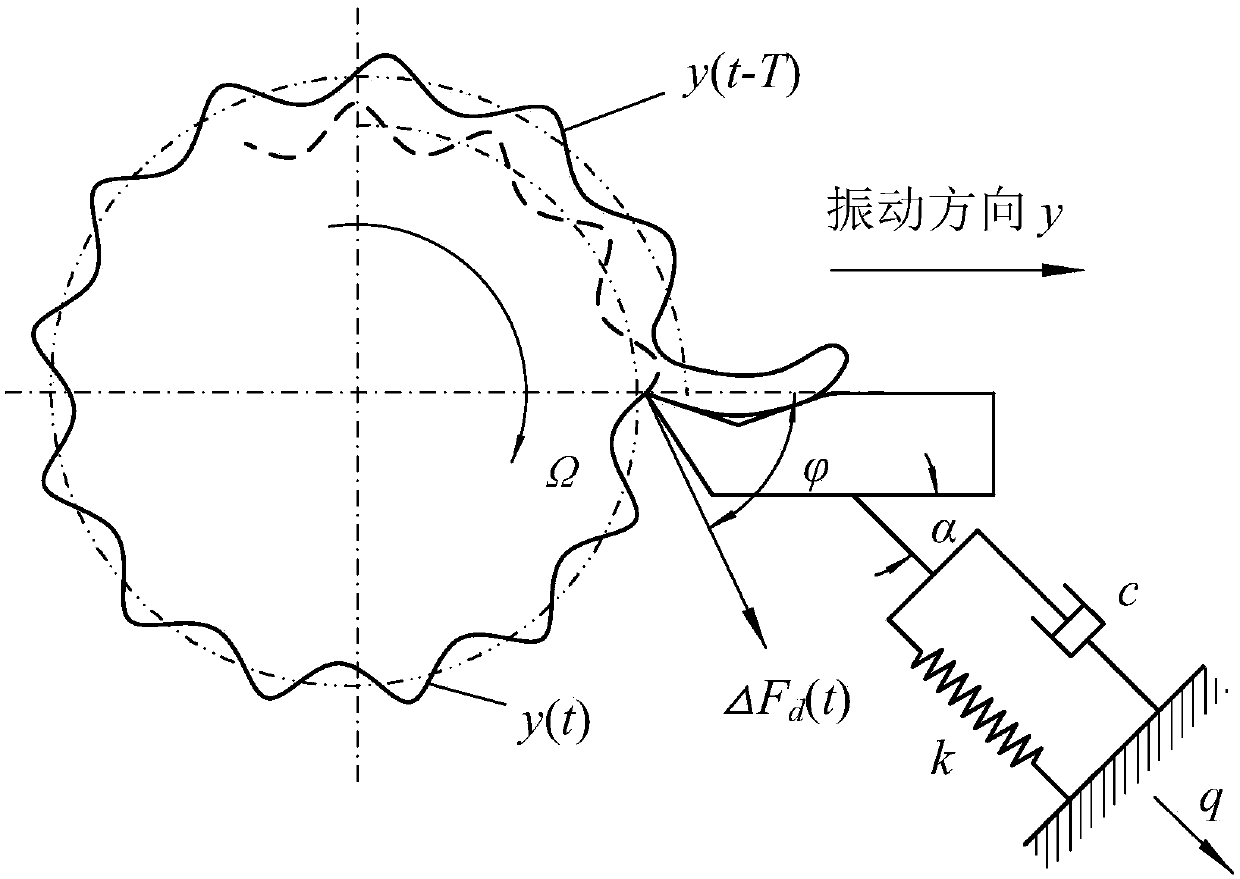

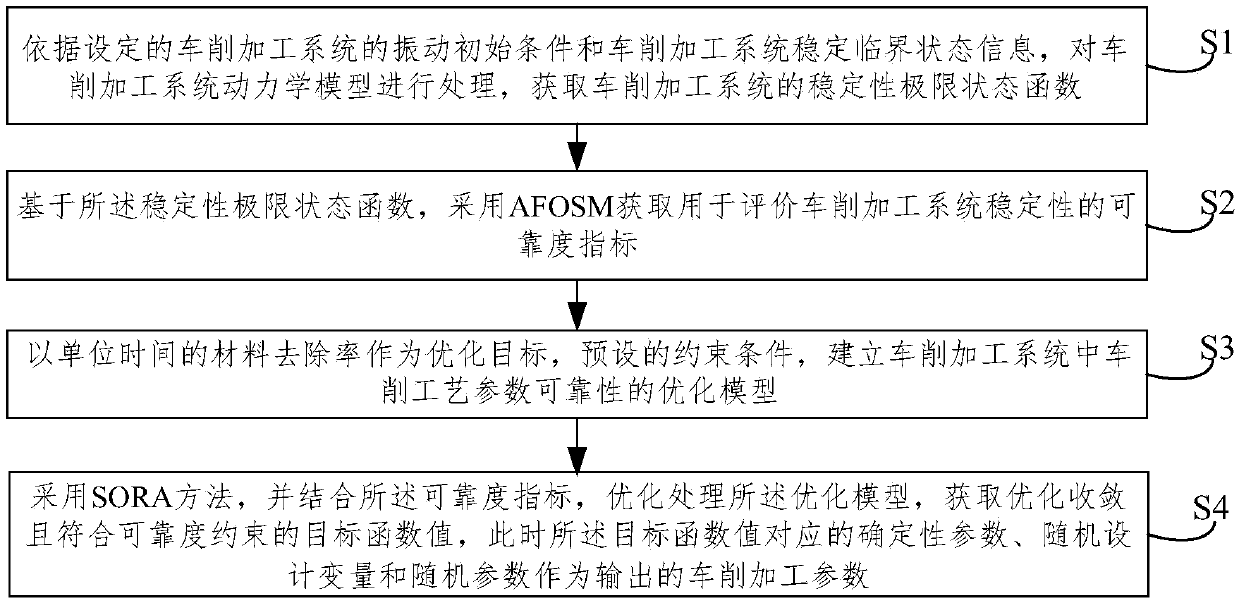

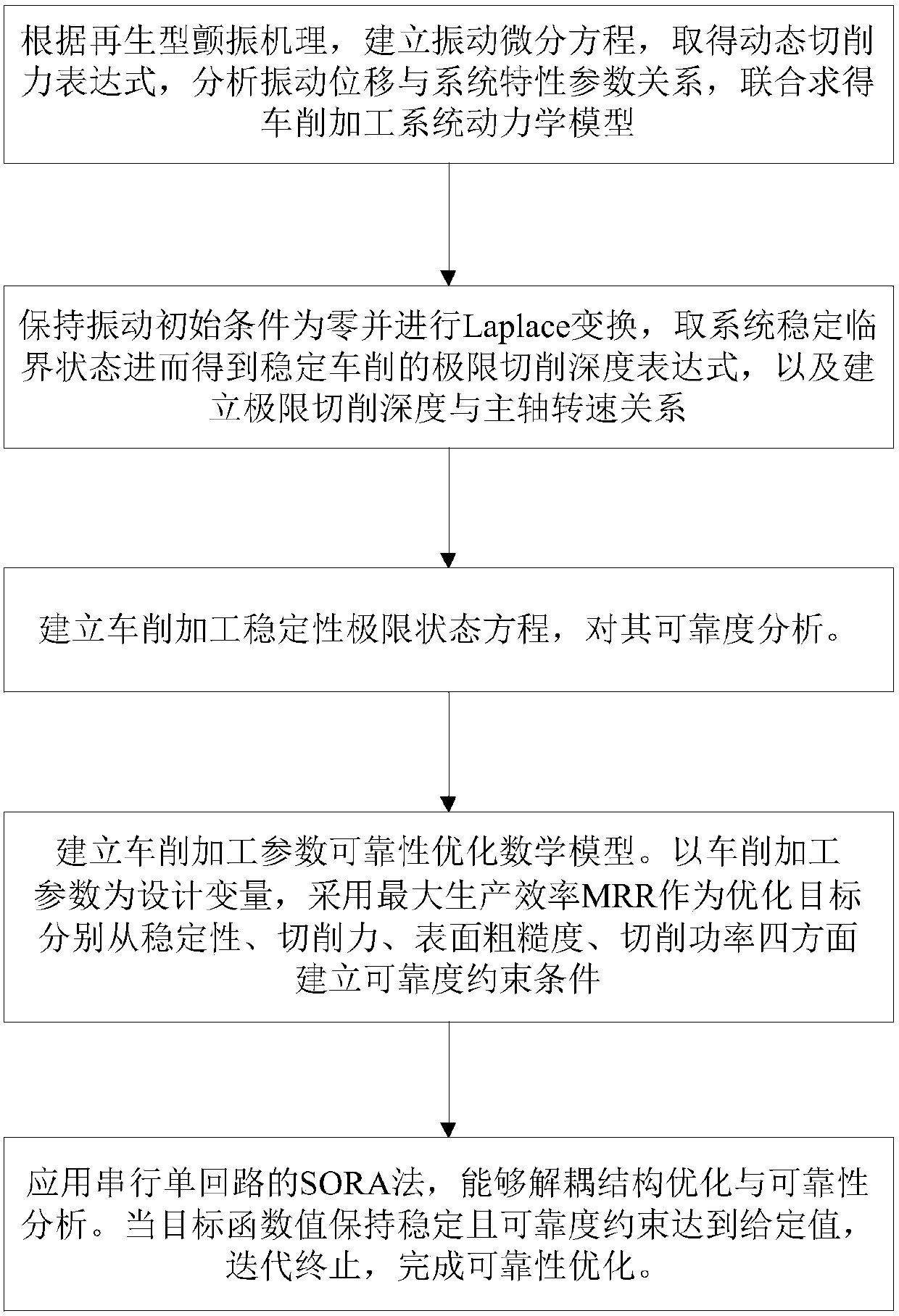

Method used

Image

Examples

Embodiment 1

[0216] Table 1 shows the design variable parameters and probability distribution characteristics of random parameters of a CNC lathe.

[0217] Table 1 Probability distribution characteristics of basic parameters

[0218]

[0219] Put the above turning dynamic parameters into the above formulas (6), (7), and (8), and different speed Ω corresponds to different limit cutting depth aplim, and the turning stability lobe diagram is obtained, as shown in Figure 4 shown. The curve divides the space into two parts, the unstable area and the stable area. If the value point is above the curve, there will be flutter phenomenon, and the point on the lobe curve is a critical state.

[0220] Apply the SORA method in step 05 to solve the reliability optimization problem. The objective function of this example is nonlinear. In the programming optimization, the MATLAB programming language can be used, and the above deterministic optimization and the deterministic optimization in the relia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com