Remaining life prediction method based on two-stage random degradation modeling

A life prediction and degradation model technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as difficult remaining life prediction, and analytical life probability density function has not been given

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0063] In order to help understand the present invention and demonstrate its effect on fault detection, an example will be described in detail below. This example is based on the MATLAB tool, using actual battery degradation data to illustrate the present invention, and demonstrates the effect of the present invention in conjunction with the accompanying drawings.

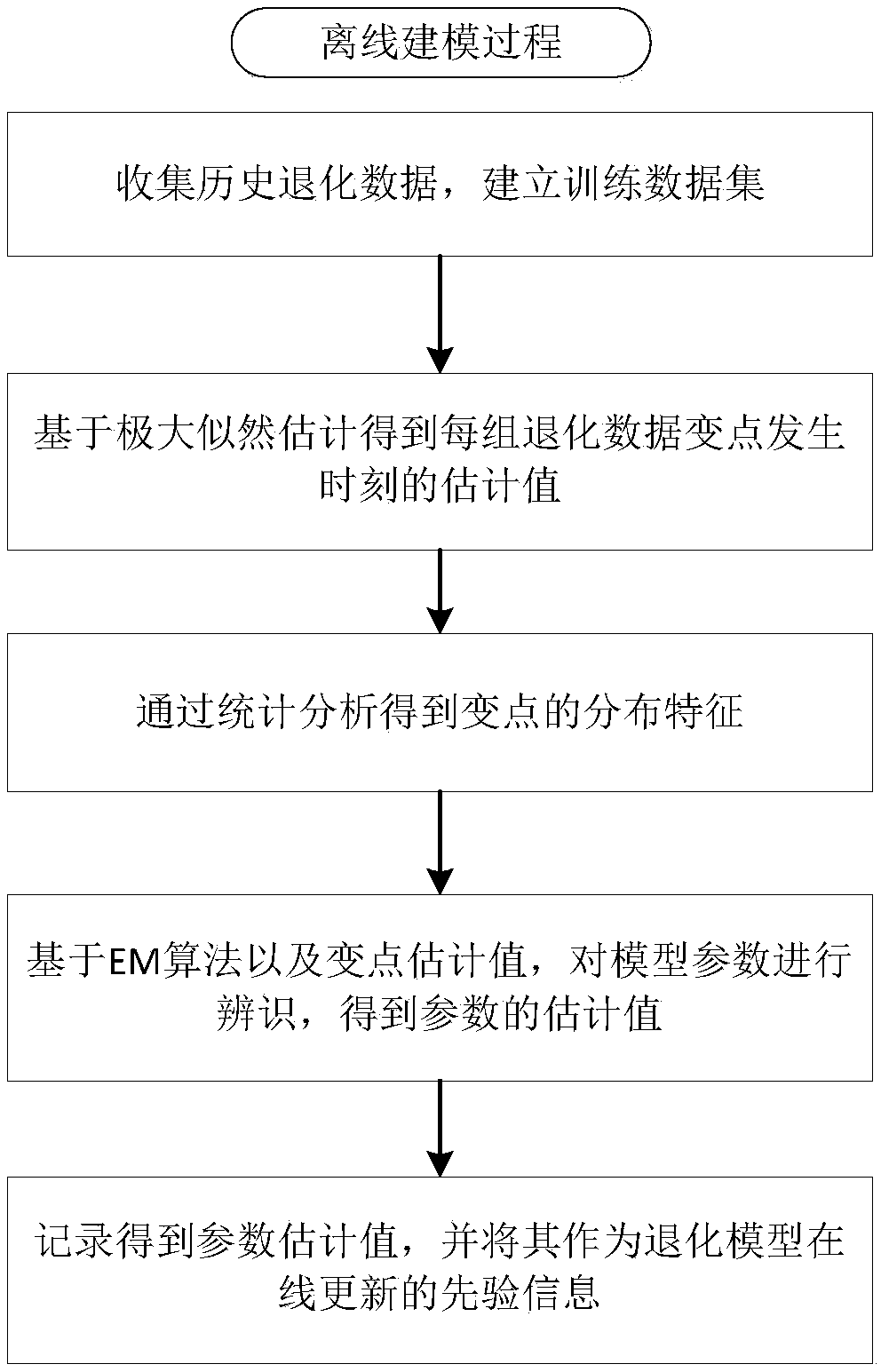

[0064] 1. The flow of the offline modeling process is as follows: figure 1 As shown, specific to this example, the specific steps are as follows:

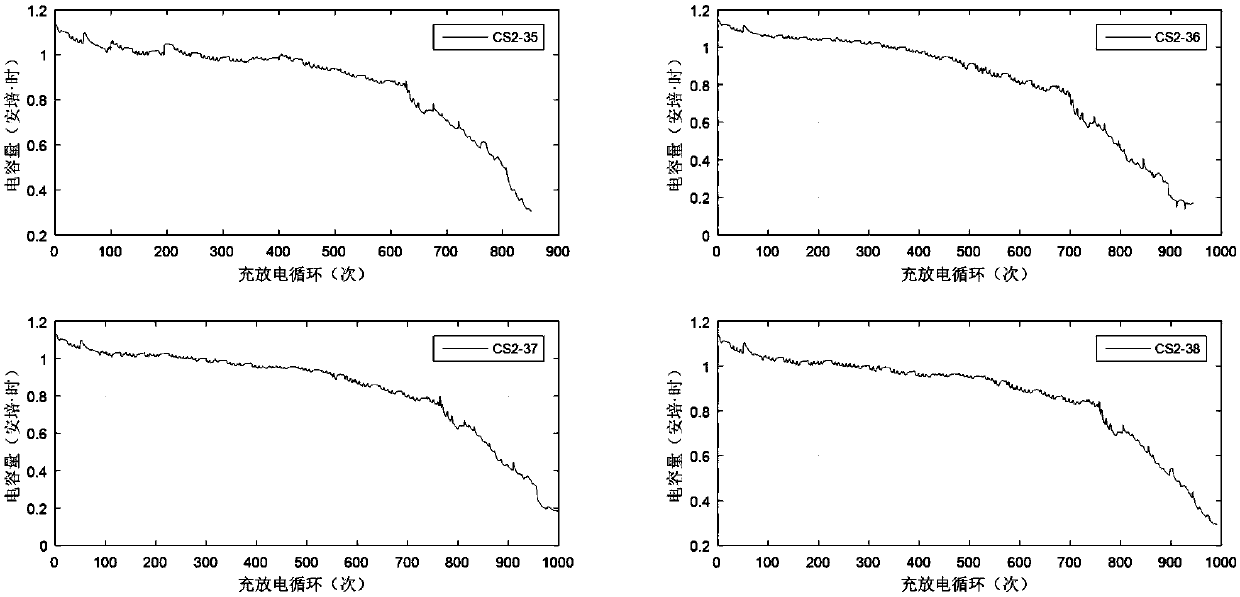

[0065] Step 1.1: Collect four sets of battery degradation data such as image 3 As shown, select three groups (CS2-35, CS2-37, CS2-38) for offline model identification;

[0066] Step 1.2: Define the two-stage degradation model as follows:

[0067]

[0068] Among them, in order to describe the difference between different samples, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com