Display substrate, manufacturing method thereof, and display device

A technology for display substrates and base substrates, which is applied in semiconductor devices, electrical components, circuits, etc., and can solve problems such as easy fracture and large stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 3

[0057] Embodiment 3 of the present invention provides a display device. The display device includes: a display substrate. The display substrate adopts the display substrate provided in Embodiment 1 or Embodiment 2 above. For details, please refer to Embodiment 1 and Embodiment 2 above. The content of the second is not repeated here.

[0058] The display device can be a product or component with a display function such as a television, a monitor, a tablet computer, a mobile phone, an electronic paper, a navigator, a digital photo frame, a video camera, a camera, and the like.

Embodiment 4

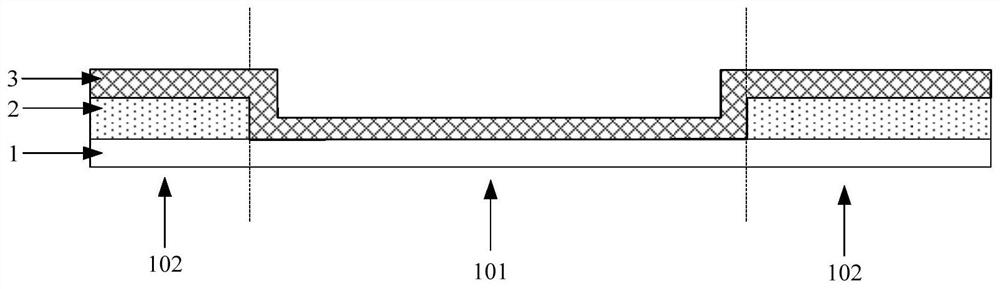

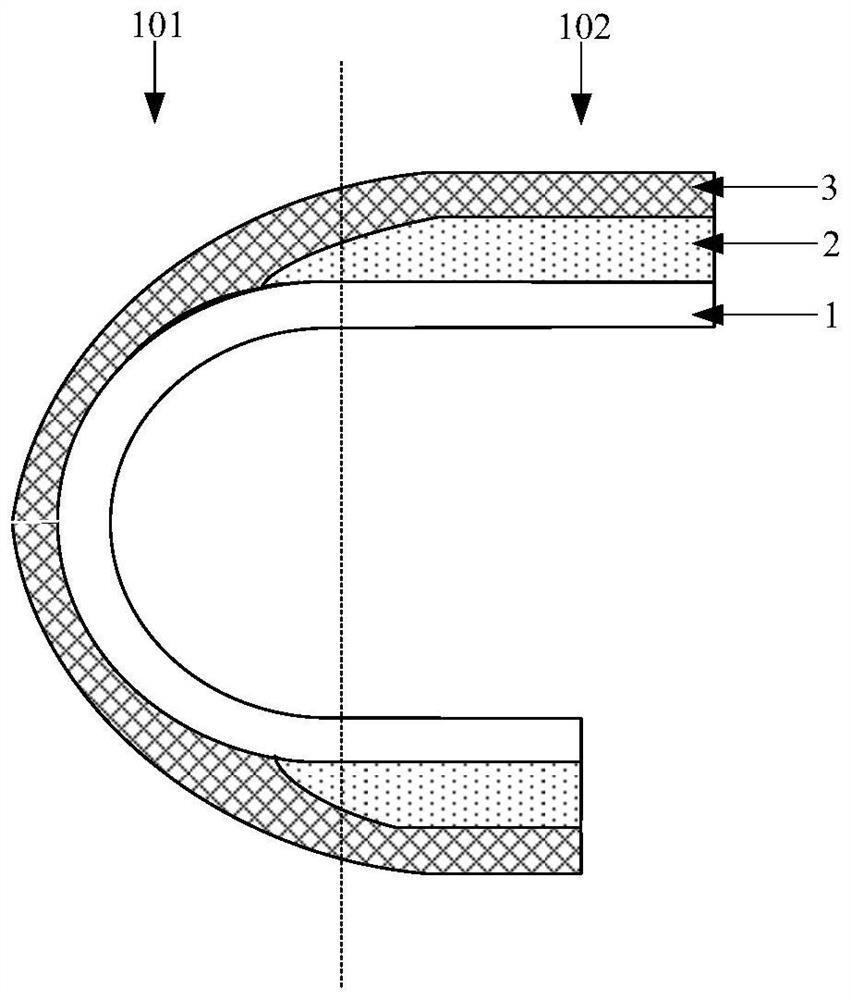

[0060] Figure 11 A flow chart of a method for preparing a display substrate provided in Embodiment 4 of the present invention, such as Figure 11 As shown, the preparation method is used to prepare the display substrates in the first and second embodiments above. The display substrate is divided into a display area and a non-display area surrounding the display area. A bending-resistant area and a frame area are set in the non-display area. The preparation method includes:

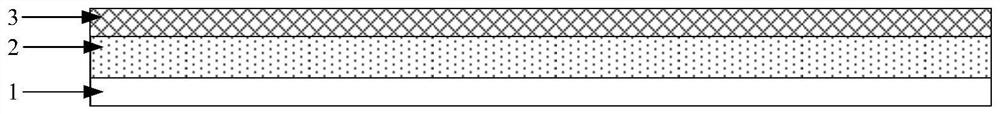

[0061] Step S1, forming an inorganic insulating layer on the base substrate at positions corresponding to the display area and the frame area.

[0062] Firstly, based on the existing thin film transistor technology, a whole-layer inorganic insulating layer is provided on the base substrate, and the inorganic insulating layer includes at least one of an inorganic buffer layer, a gate insulating layer, and an interlayer insulating layer. Then, the portion of the inorganic insulating layer corresponding to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com