Plasma sheath curvature measurement method of ion thruster

An ion thruster and plasma technology, applied in the directions of plasma and electrical components, can solve the problem of not considering the curvature of the plasma sheath, and achieve the effect of ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below with reference to the accompanying drawings and examples.

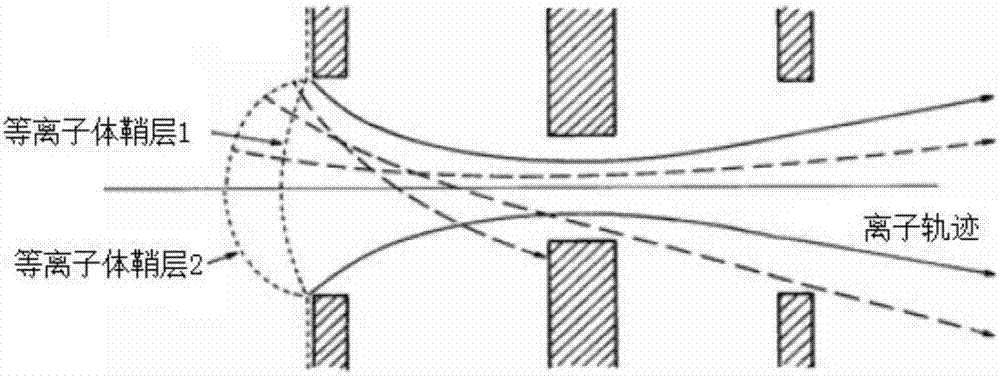

[0022] The invention provides a method for measuring the curvature of the plasma sheath of an ion thruster. The basic principle is to measure the plasma density based on the fact that the plasma density on the curved surface of the sheath is everywhere equal and the plasma density at the downstream adjacent position changes abruptly, so as to find out Sheath surface, and get the sheath curvature.

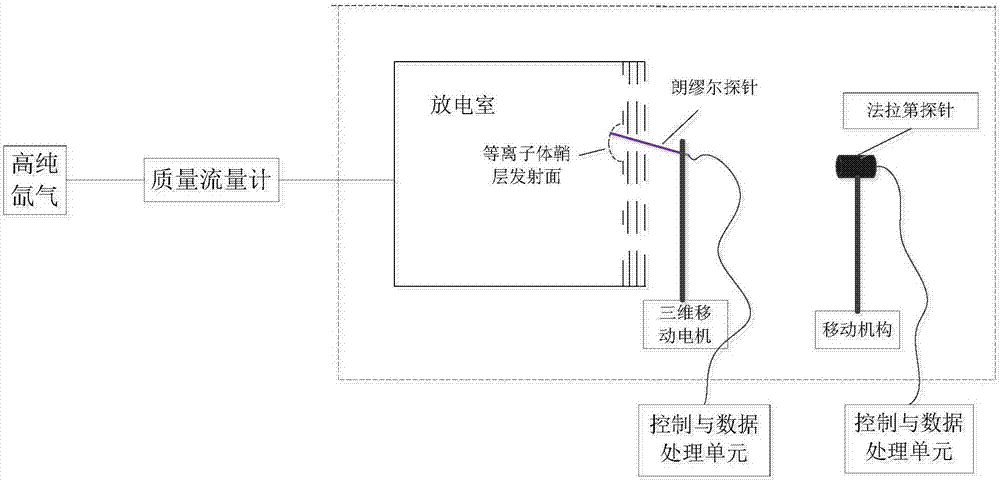

[0023] Such as figure 2 Shown is the plasma sheath curved surface measuring device of the present invention. The measuring device consists of a gas supply device, a mass flow meter, a Langmuir probe, a Faraday probe, a three-dimensional precision moving motor, and a control and data processing unit.

[0024] The measurement implementation steps are as follows:

[0025] Step 1. Change the gas flow rate of the high-purity xenon gas provided externally and dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com