Immersed type liquid cooling apparatus, blade type server and frame type server

A blade server, rack server technology, applied in cooling/ventilation/heating renovation, electrical components, electrical equipment structural parts, etc., can solve the problem of inconvenient maintenance of electronic components, high production costs Problems such as low heat dissipation efficiency, to achieve the effect of improving maintenance efficiency, facilitating maintenance, and improving heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

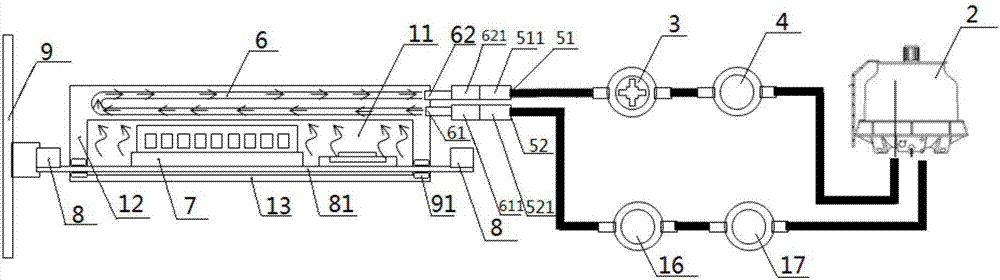

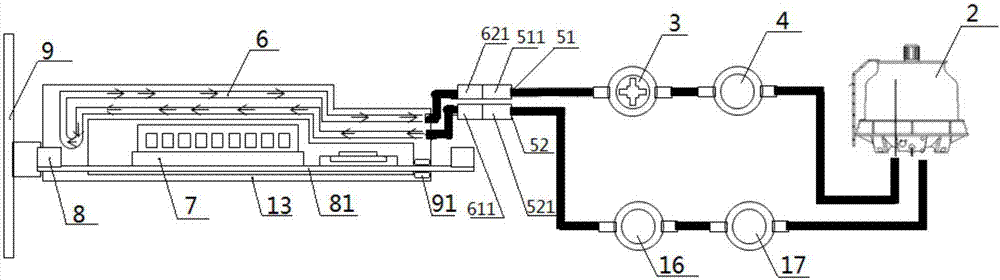

[0031] figure 1 It is a schematic diagram of a longitudinal section structure of a liquid cooling device provided in this application. like figure 1 As shown, the liquid cooling device includes a housing and an external cooling device 2 . Figure 4 Further shows the exploded structure of the shell, as Figure 4 As shown, the shell includes a hollow shell body 12 , a bottom plate 13 and a top plate 14 , the three are sealed and connected to form a closed cavity 11 , and a flow channel 6 is opened on the body of the top plate 14 .

[0032] The casing includes a closed cavity 11, and electronic components 7 to be dissipated are installed in the closed cavity 11. The first cooling liquid is filled in the airtight cavity 11 , is filled with the airtight cavity 11 , and is in direct contact with the electronic components 7 to be dissipated. exist figure 1 In the shown liquid cooling device, the flow channel 6 is not connected to the closed cavity 11 , but is connected to the ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com