Graded screening machine for live fishes

A technology for grading screening and live fish, applied in fish sorting and other directions, can solve problems such as low classification efficiency, limited separation grid area, fish body damage, etc., to achieve the effect of improving classification efficiency, wide application range and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. According to the following description, the purpose, technical solution and advantages of the present invention will be more clear. It should be noted that the described embodiments are preferred embodiments of the present invention, but not all embodiments.

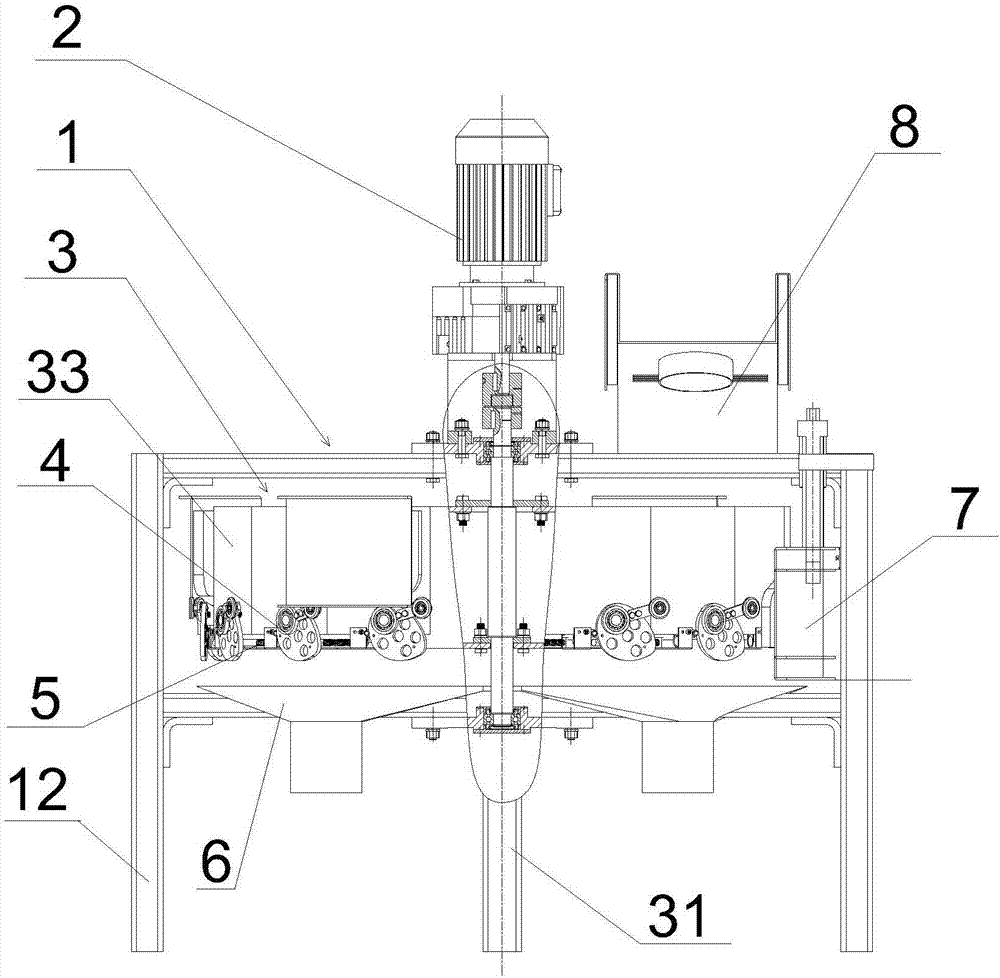

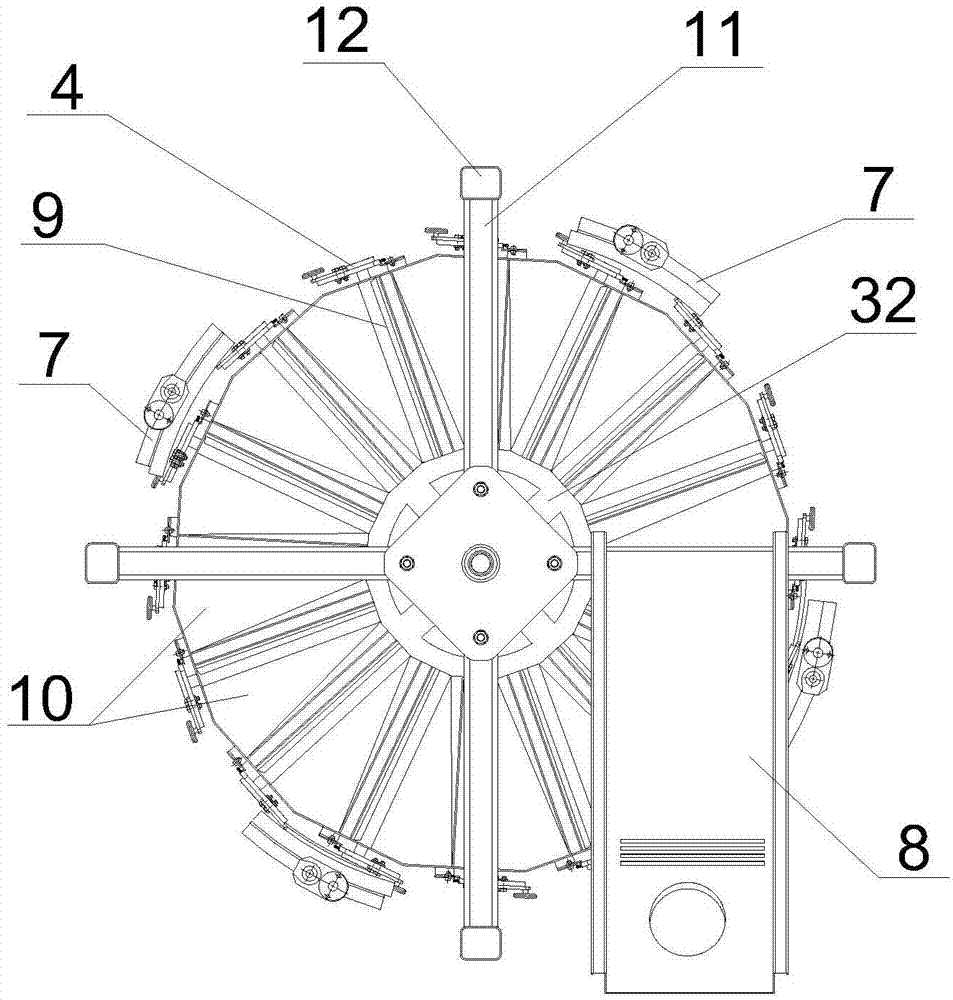

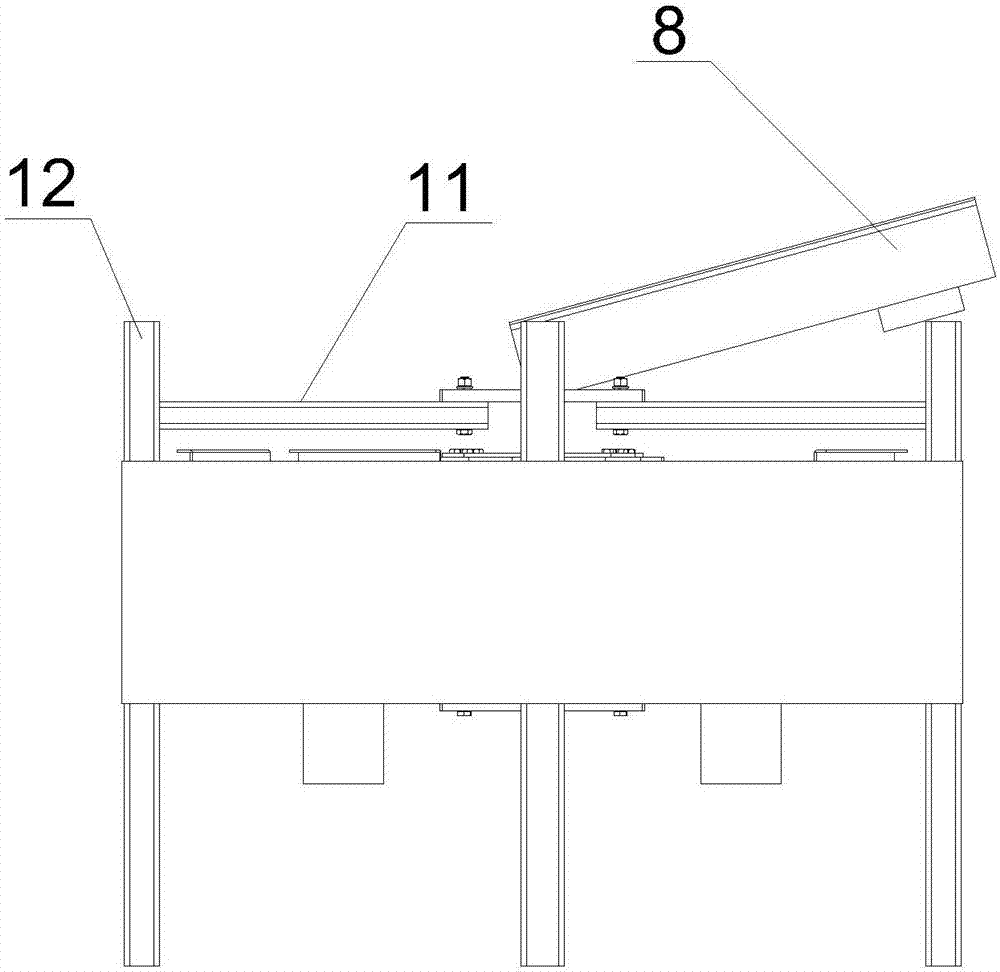

[0032] combine figure 1 , figure 2 with image 3 As shown, a live fish grading and screening machine includes a frame 1, on which a horizontal rotary mechanism 3 driven by a motor 2, a fish feeding bucket 8 and a horizontal rotary mechanism installed above the horizontal rotary mechanism 3 are installed on the frame 1 4 below water-filled fish buckets 6 and 4 cam adjustment plates 7 positioned at the outside of the horizontal slewing mechanism 3 . The frame 1 includes two horizontal bars 11 connected in a cross shape and a vertical bar 12 connected at the ends of the horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com