A kind of preparation method of japonica rice noodle

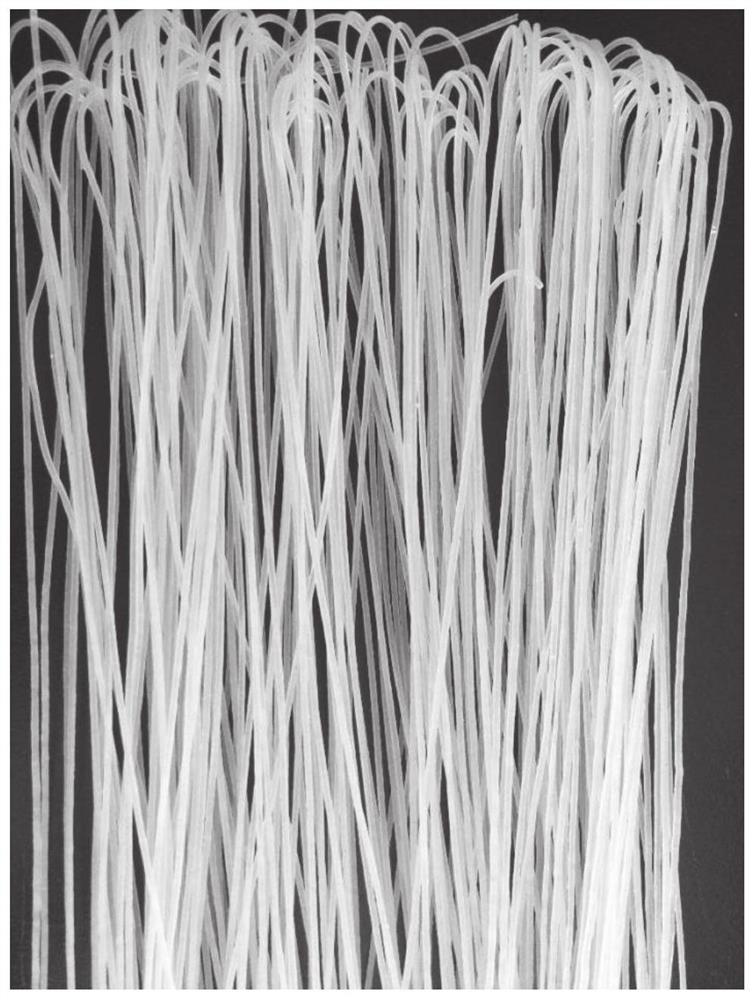

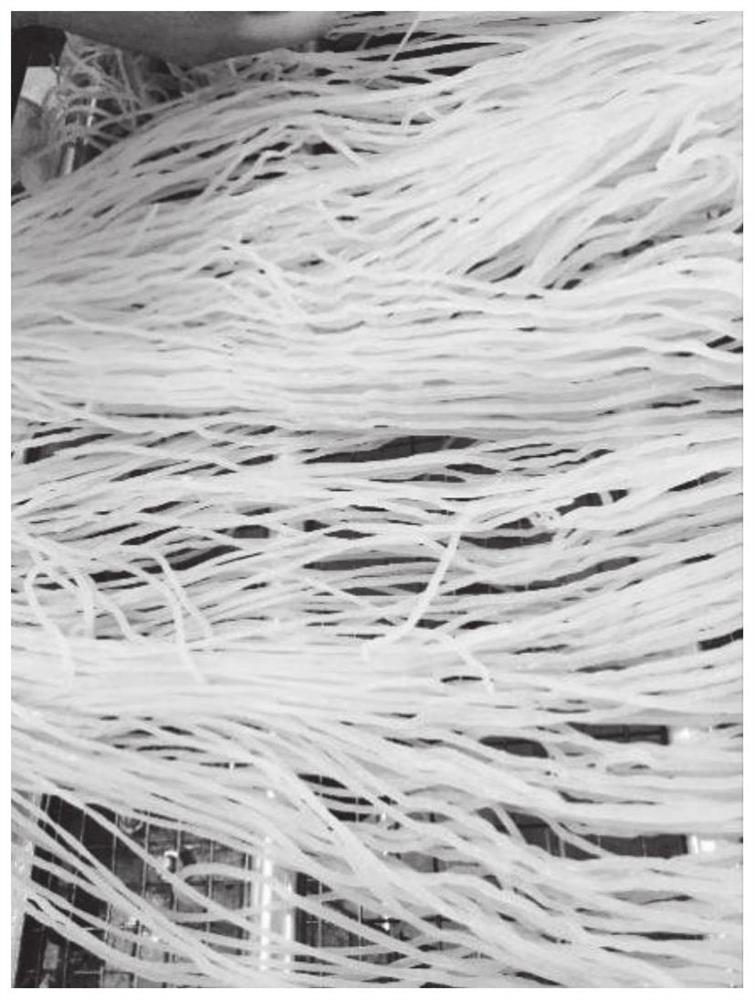

A technology of japonica rice noodle and production method, which is applied in food science and other fields, can solve the problems of affecting the taste of japonica rice, difficulty in shredding and aging, high viscosity of japonica rice, etc., and achieve the effects of easy shredding, reduced viscosity, and strong rice flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069]The preparation method of the glutinous rice niline of the present embodiment includes the following steps:

[0070](1) Bud glutinous rice preparation: Take a full japonica rice with grain, after the grain, remove impurities, mildew and different grains; after ozone sterilization, the germination temperature is controlled at 30 ° C (30 ± 2 ° C) , Moisture is 80%, the germination time is 48h, dry, and the mill is germinated;

[0071](2) Soak: Soak the germinated glutinous rice in the rice water than 1: 2, so that the rice particles are sufficiently absorbed and swelled, and the rice granules can be broken after soaking;

[0072](3) Centrifugation dehydration, spiral cutting: Put the raw material obtained by step (2) in centrifugation in the centrifugal dehydration machine (control the water content of 35 ~ 45%), then pulverized with a spin cutting machine, over 80 mesh Sieve, glutinous rice noodles;

[0073](4) Infrared pre-gelation: mixed the glutinous rice powder obtained by step (3) wit...

Embodiment 2

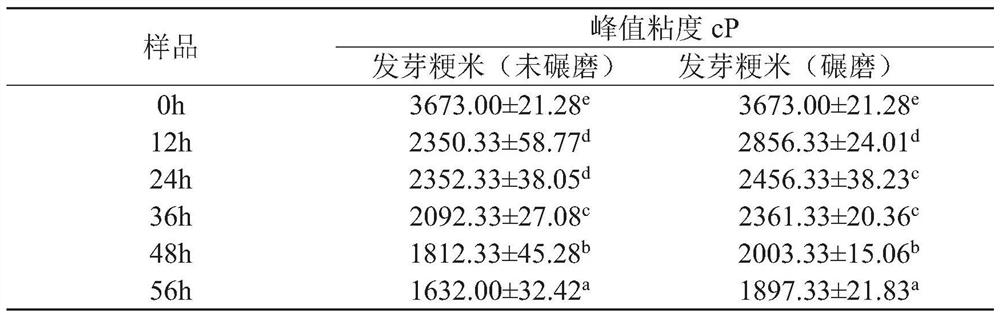

[0078]As compared with Example 1, the difference is only in that, in step (1), the milling rice is not performed; that is, the germination glutinous rice is directly obtained after germination. The present inventors pass the peak viscosity of germinated glutinous rice by testing Example 1 and Example 2, and data is shown in Table 1; Table 1

[0079]

[0080]Note: The data is averaged ± standard deviation of three measurements; different letters in the same column indicate significant differences (P <0.05)

[0081]As can be seen from Table 1, germination can significantly reduce the viscosity of glutinous rice flour. The germination treatment has a large effect on the peak viscosity of the glutinous rice powder, and the peak viscosity is characterized by the thermal processing of glutinous rice. This peak viscosity will decrease significantly with the increase in sprouting time.

Embodiment 3

[0083]The preparation method of the glutinous rice niline of the present embodiment includes the following steps:

[0084](1) Soaking: Soak the glutinous rice in the rice water than 1: 2, so that the rice particles are sufficiently absorbed and swelled, and the rice granules can be broken after soaking;

[0085](2) Centrifugation dehydration, spiral crushing: The raw material obtained by step (1) in centrifugation was dehydrated in the centrifugal dehydration machine, and then pulverized with a spin cutting mill, over 80 mesh sieve, and glutinous rice noodles;

[0086](3) Infrared preframetization: mix the glutinous rice powder obtained by step (2) with 30% of the water equivalent to the glutinous rice flour, still 20min a balanced moisture at normal temperature, then placed in an infrared drying box, temperature 100 ° C Infrared power 16KW processing 3min

[0087](4) Squeeze and ripening and a silk: The glutinous rice powder treated by step (3) is placed in an auto-crushing rogue machine, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com