Machining method for tapered shaft sleeve

A processing method and technology of tapered shafts, which are applied in metal processing equipment, manufacturing tools, grinding machine parts, etc., can solve problems such as affecting the health of operators, and achieve the advantages of reducing scrap rate, simple process and reducing production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0037] Embodiment: A processing method of a tapered bushing in this scheme includes the following steps: (1) cutting the wire blank into several sections of bar blanks;

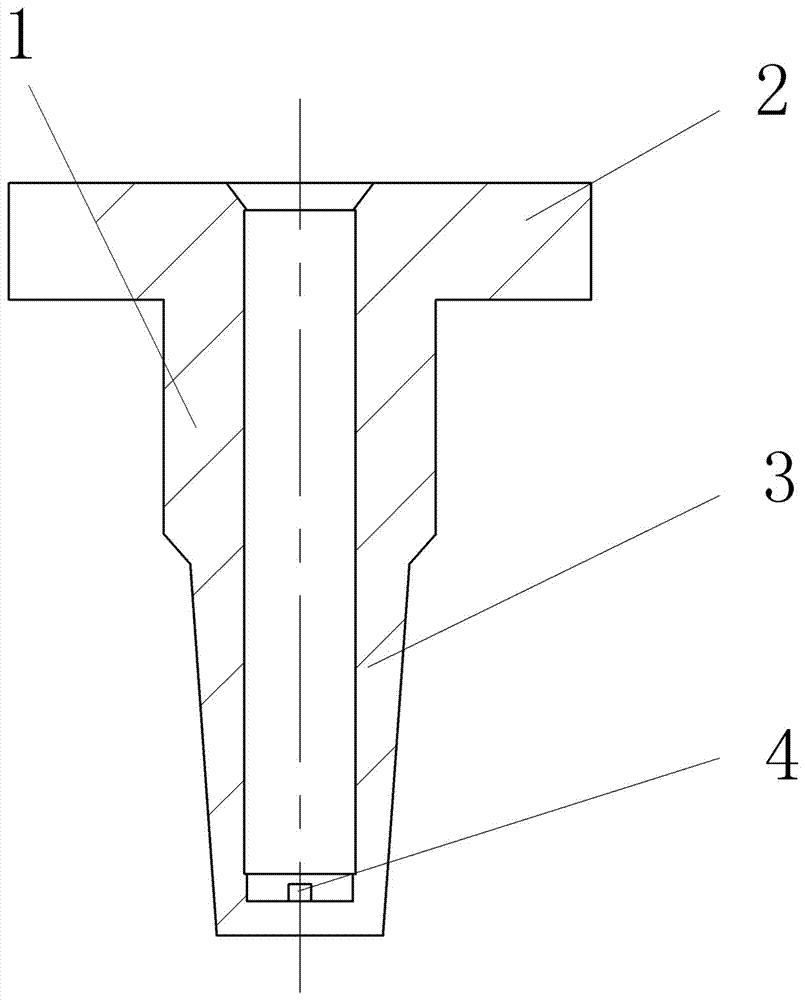

[0038] (2) if figure 1 As shown, one end of the rod blank is upset, and the other end is stretched to expand the diameter. The upsetting part on the rod blank forms the third rod body blank 2, and the reduced diameter part on the rod body blank forms the first rod body blank 3. A second rod body blank 1 is formed at the part between the upsetting part and the diameter reduction part on the piece blank, and a chamfer is processed between the first rod body blank 3 and the second rod body blank 1, and the outer end of the first rod body blank 3 is also Process a chamfer first;

[0039] (3) Flatten the outer surface of the third rod blank 2 first, and then stretch a round hole on the outer end of the third rod blank 2, and the round hole extends to the intersection position of the second rod blank 1 and the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com