Automatic exhaust method of electronic unit pump

A technology of automatic exhaust and unit pump, which is applied to engine components, combustion engines, machines/engines, etc., and can solve problems such as time-consuming and cumbersome operation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with embodiment the present invention is described in further detail:

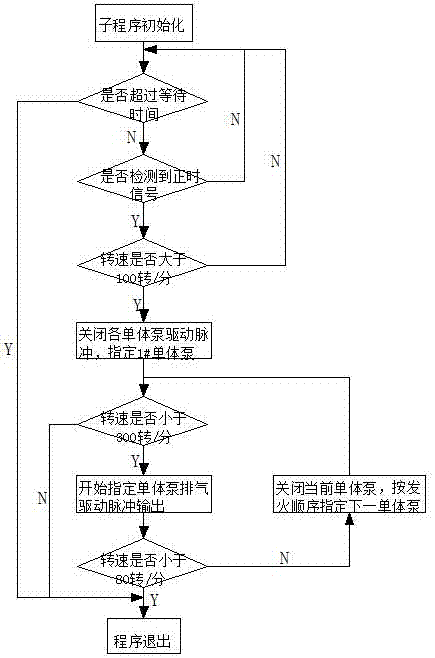

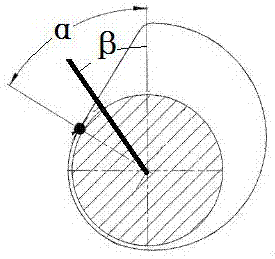

[0022] The electronically controlled unit pump automatic exhaust method, by adding an exhaust subroutine to the existing electronic control system, when the unit pump intake occurs, enter the exhaust subroutine, under the control of the exhaust subroutine The engine moves over 120 rpm under the drag of the starter motor. The starter motor drives the engine flywheel and crankshaft, and then drives the oil supply camshaft through the gear. During the ascending stage, the driving pulse covering the entire ascending stage of the piston is output to the solenoid valve of the unit pump, and the solenoid valve is in the closed state, among which figure 2 As shown, in normal operation, it is only necessary to give the solenoid valve a narrow driving pulse corresponding to the rotation angle β of the oil supply cam in the rising stage. correspond. The unit pump sends the fuel sucked i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com