Vehicle brake cable

A technology for brake lines and automobiles, which is applied in the field of auto parts, can solve the problems of easy breakage and insufficient tensile elasticity of the outer casing of the brake line, and achieves the effects of not easy to break, good flexibility, and increased tensile elasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

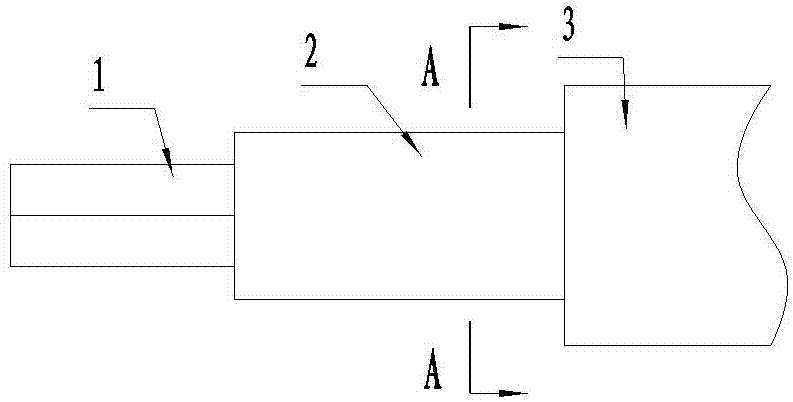

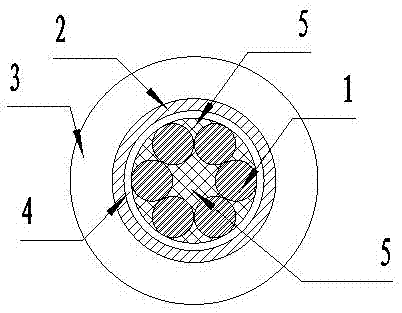

[0011] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

[0012] Such as figure 1 , figure 2 The automobile brake wire shown includes a wire core and a rubber outer sleeve 3 set outside the wire core. The wire core is composed of multiple strands of steel wire 1 whose cross-section is arranged in a plum blossom shape. The steel wire is a high-carbon steel wire with a diameter of 3 mm. There is a metal inner casing 2 between the wire core and the outer sleeve, and an internal thread 4 is provided on the inner wall of the inner casing. AB glue 5 is filled between the inner sleeve 2 and the wire core; when assembling, the outer wall of each strand of steel wire is first coated with AB glue, and then put into a quincunx shape and squeezed into the inner sleeve so that the AB glue is completely embedded. Into the internal thread, so that the inner sleeve and the steel wire are tightly combined, and then fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com