Evaporative cooling type centrifugal chiller and system with same

An evaporative cooling and chiller technology, applied in refrigerators, refrigeration components, compressors, etc., can solve the problems of low energy efficiency, unfriendly surrounding environment, and large loss of circulating water in cooling towers, achieving less power consumption and energy saving. Significant, reduced drift loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

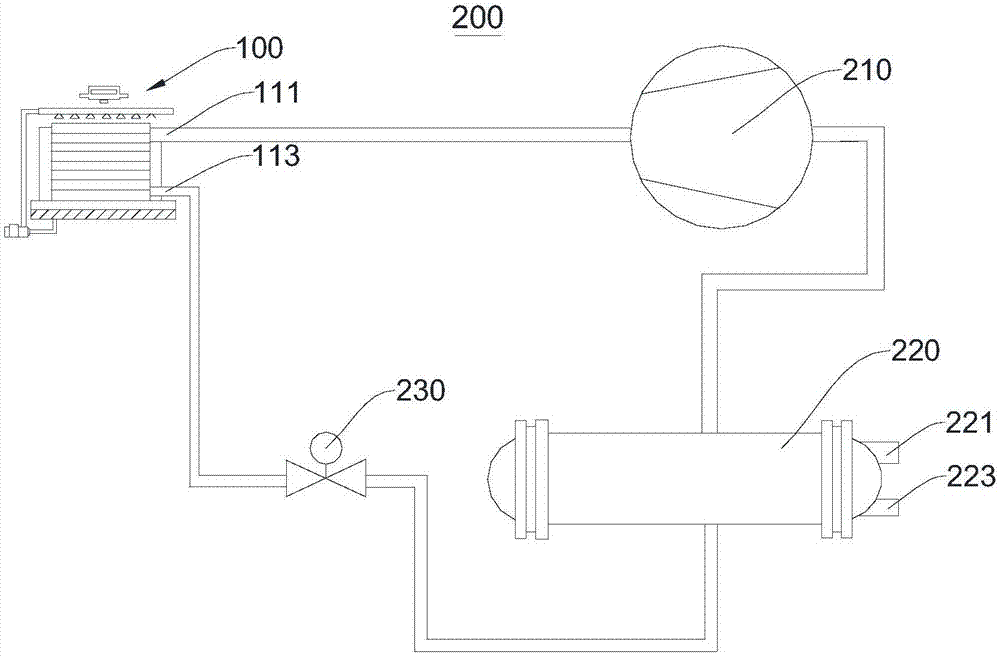

[0034] Please refer to figure 1 and figure 2 , this embodiment provides an evaporative cooling centrifugal chiller 200, including a compressor 210, an evaporative condenser 100, a throttling element 230, and an evaporator 220 connected in sequence, and the evaporator 220 is connected to the compressor 210 to form a refrigeration circuit .

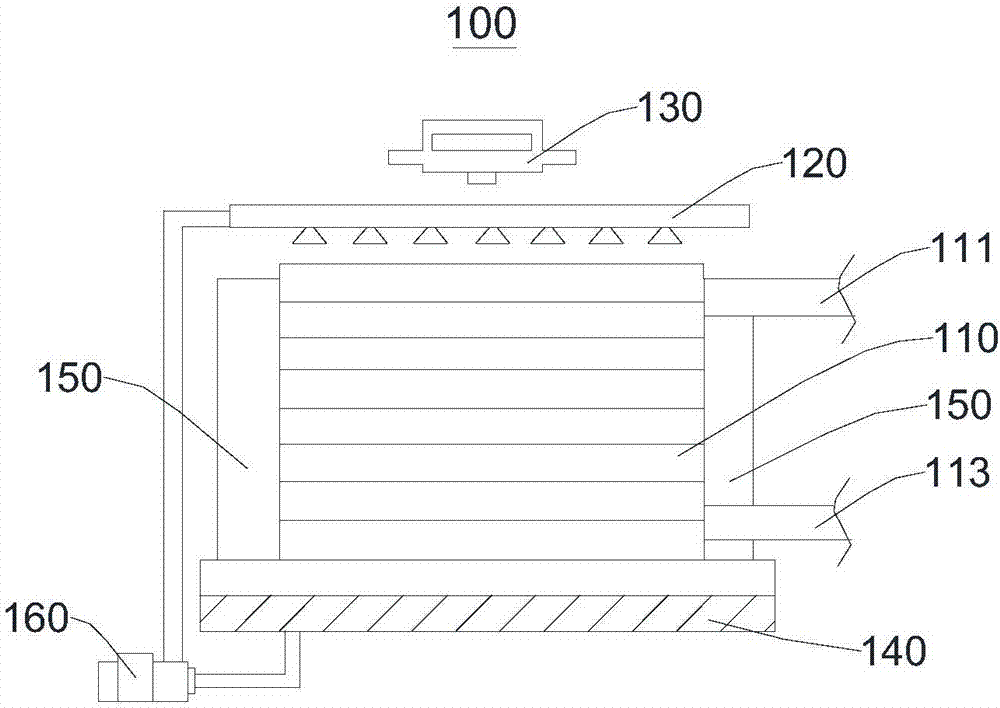

[0035] The evaporative condenser 100 includes a heat exchanger 110 , a water sprayer 120 , a cooling fan 130 , a water receiving tray 140 , a water blocker 150 and a water pump 160 . The water sprayer 120 is disposed on the top of the heat exchanger 110 , that is, above. The cooling fan 130 is disposed on a side of the sprinkler 120 away from the heat exchanger 110 . The water receiving tray 140 is arranged at the bottom of the heat exchanger 110 , and the water blocker 150 is arranged at the left and right sides of the heat exchanger 110 . The water sprayer 120, the water pump 160, the water receiving tray 140 and the heat exchanger 1...

Embodiment 2

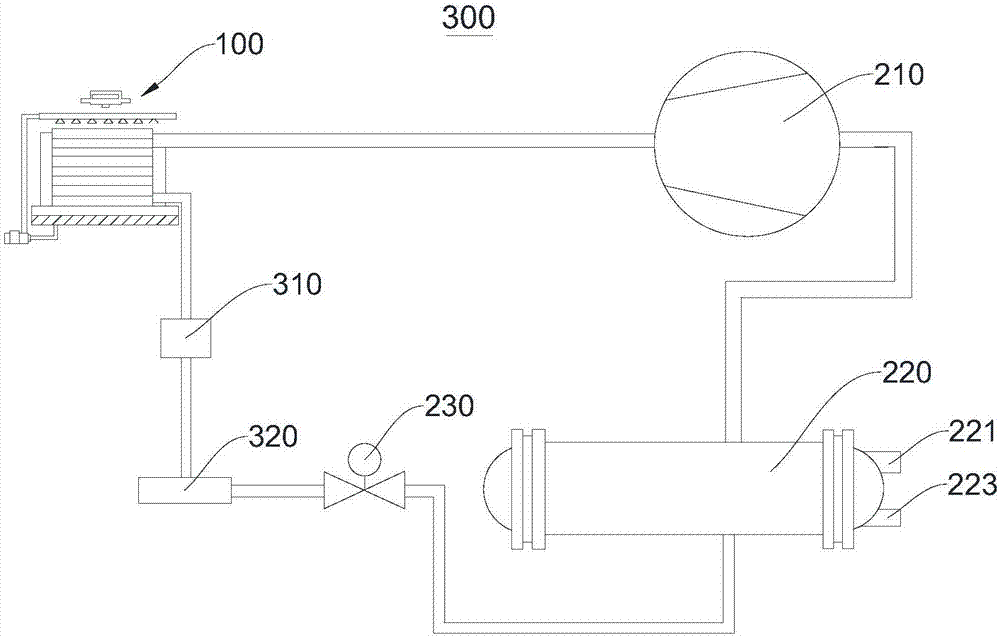

[0046] Please refer to image 3 , this embodiment provides an evaporative cooling centrifugal chiller 300 .

[0047] The difference between the evaporative cooling centrifugal chiller 300 and the evaporative cooling centrifugal chiller 200 mainly lies in:

[0048] The evaporative cooling centrifugal chiller 300 includes an accumulator 310 for storing refrigerant, and the accumulator 310 is respectively connected with the evaporative condenser 100 and the throttling element 230 . The accumulator 310 is configured to receive the refrigerant flowing out of the evaporative condenser 100 and input the refrigerant to the throttling element 230 .

[0049] The evaporative cooling centrifugal chiller 300 also includes a filter 320 for filtering the refrigerant output from the accumulator 310 . When there are impurities and other precipitated substances in the refrigerant, it will affect the normal operation of the evaporative cooling centrifugal chiller 300 . The filter 320 filters o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com