Semiconductor laser light source module for realizing circular light spot and side surface pumping apparatus

A light source module, laser technology, applied in the direction of semiconductor lasers, lasers, laser parts, etc., can solve the problems of long system volume, energy loss, cost increase, etc., to achieve the effect of small size, small stray light influence, easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The application of side pumping of semiconductor lasers will be described in detail below in conjunction with the accompanying drawings.

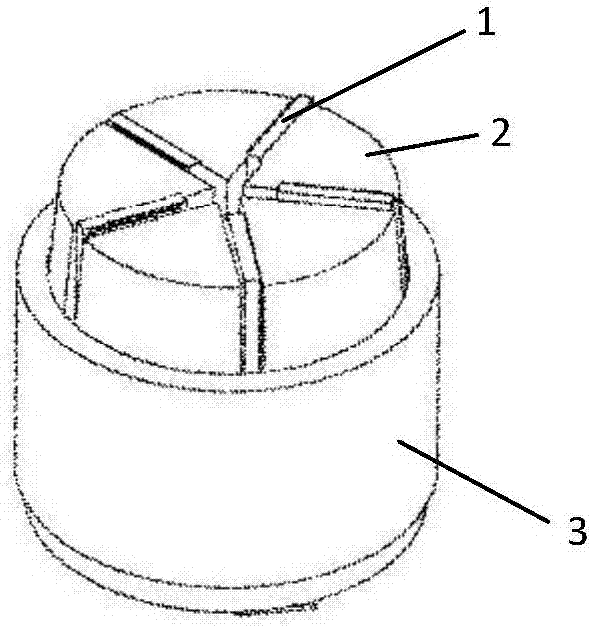

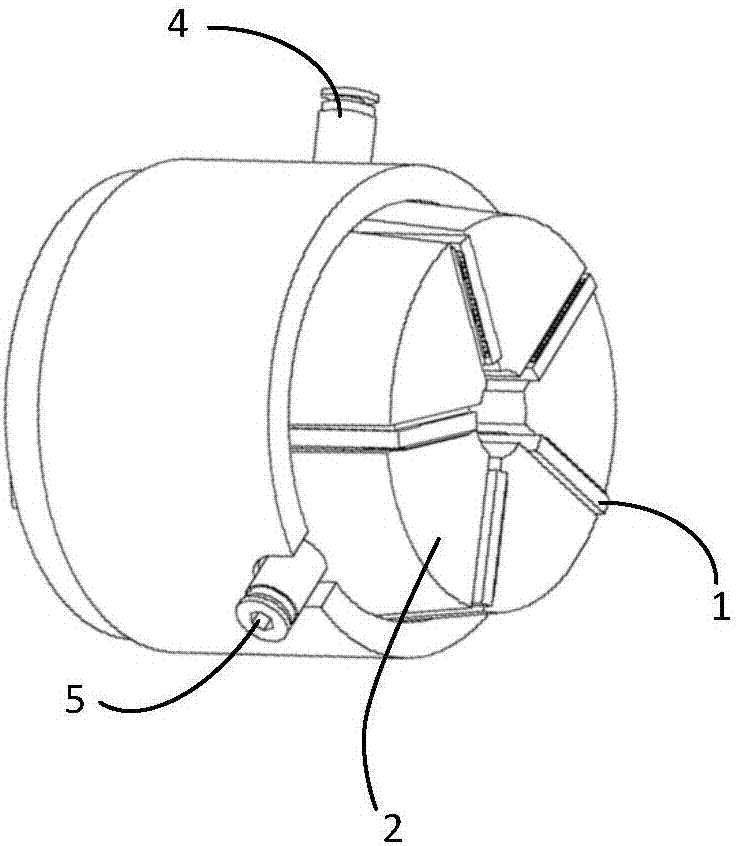

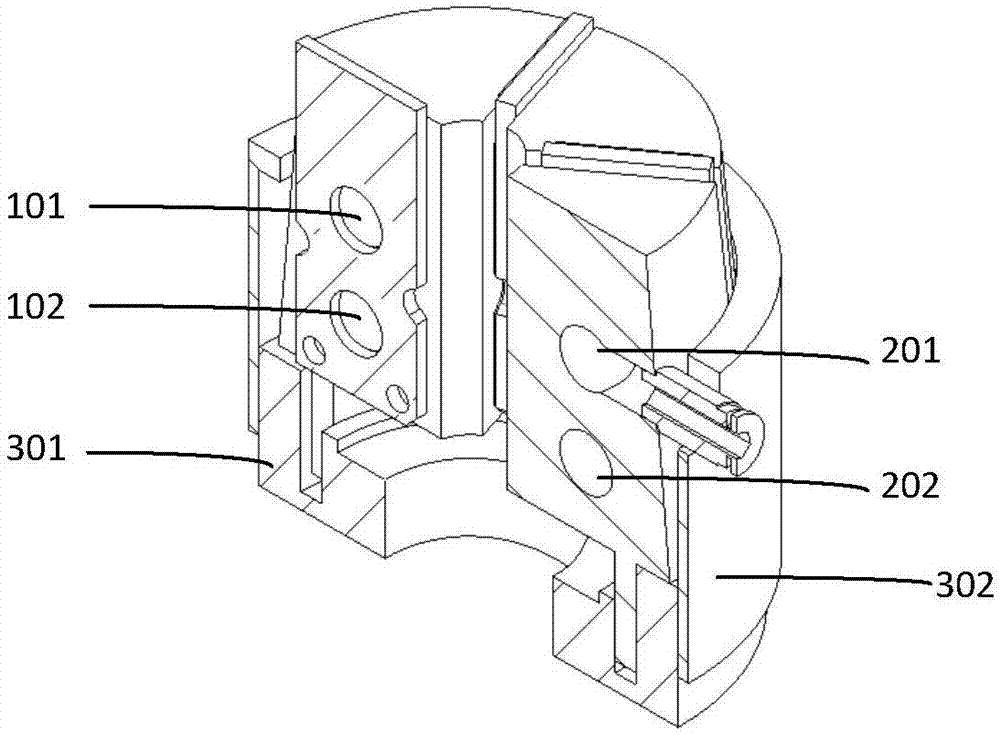

[0042] Such as figure 1 As shown, the semiconductor laser light source module includes a plurality of semiconductor lasers 1. The semiconductor lasers 1 include a chip cooler and a laser chip bonded thereon. These semiconductor lasers are arranged in a ring as a whole, and the light output direction is parallel to the central axis of the ring structure. Between the adjacent semiconductor lasers, the segmented clamping block 2 is filled, so that the overall end face formed by the plurality of semiconductor lasers 1 and the segmented clamping block 2 is a circular surface; A locking device 3 is provided for tightening and fixing all semiconductor lasers toward the center.

[0043] Among all the fan-shaped clips, at least one is an insulating clip, and the others are conductive clips. Each semiconductor laser conducts electricity in se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com