A composite photocatalytic diatom plate and its preparation method

A technology of composite photocatalytic diatom board and photocatalytic diatom board, which is applied in the field of photocatalysis, can solve the problems of easy falling off of nano photocatalyst particles and poor photocatalytic ability, and achieve strong binding force, low production cost and easy operation. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing a composite photocatalytic diatom plate, comprising the following steps:

[0036] (1) mixing alcohol, retarder and soluble titanium source to obtain the first mixed solution;

[0037] (2) mixing alcohol, water and soluble iron source, adjusting the pH value of the mixed solution to 1-3 with acid to obtain the second mixed solution;

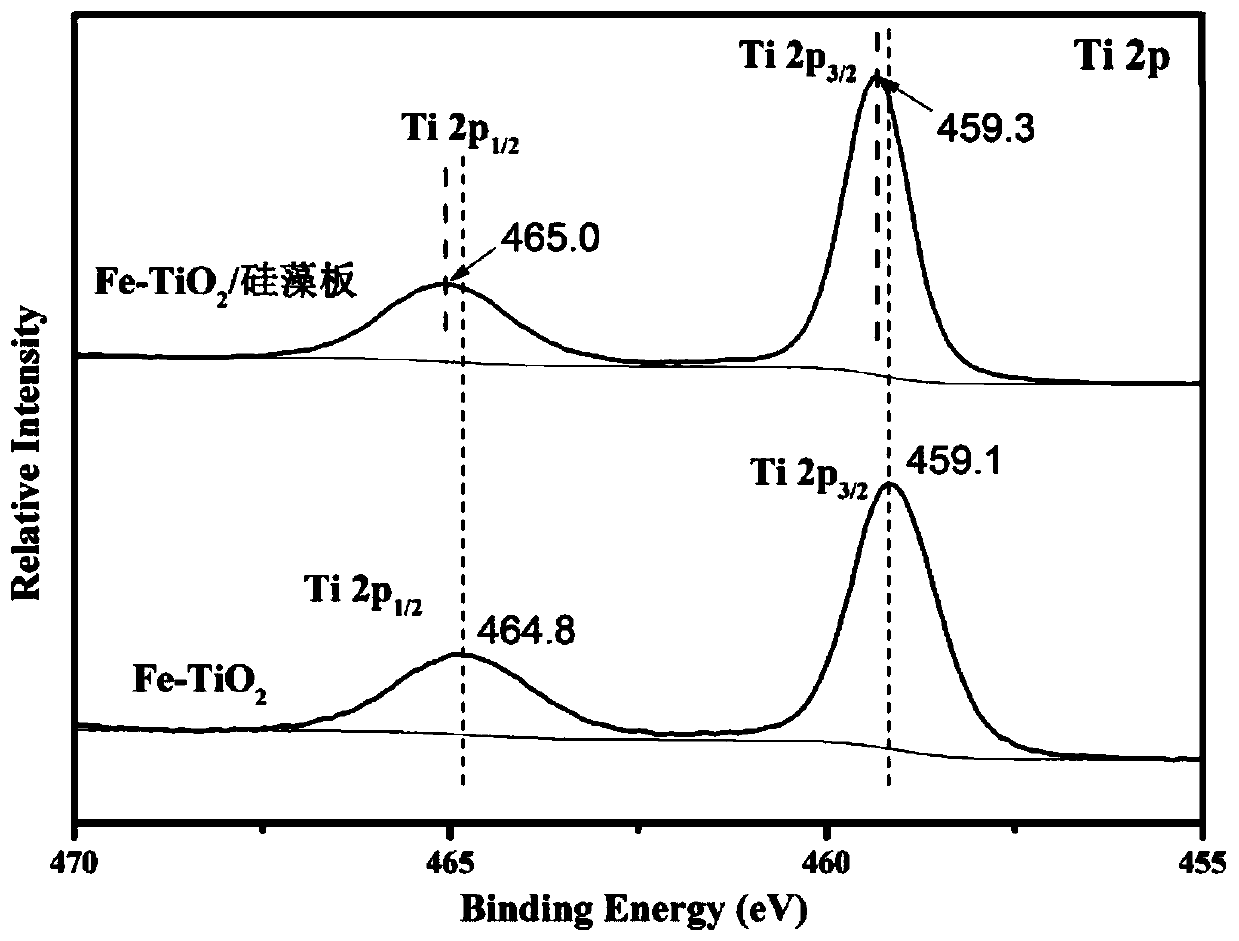

[0038] (3) adding the second mixed solution to the first mixed solution for sol-gelling reaction to obtain Fe-TiO 2 gel;

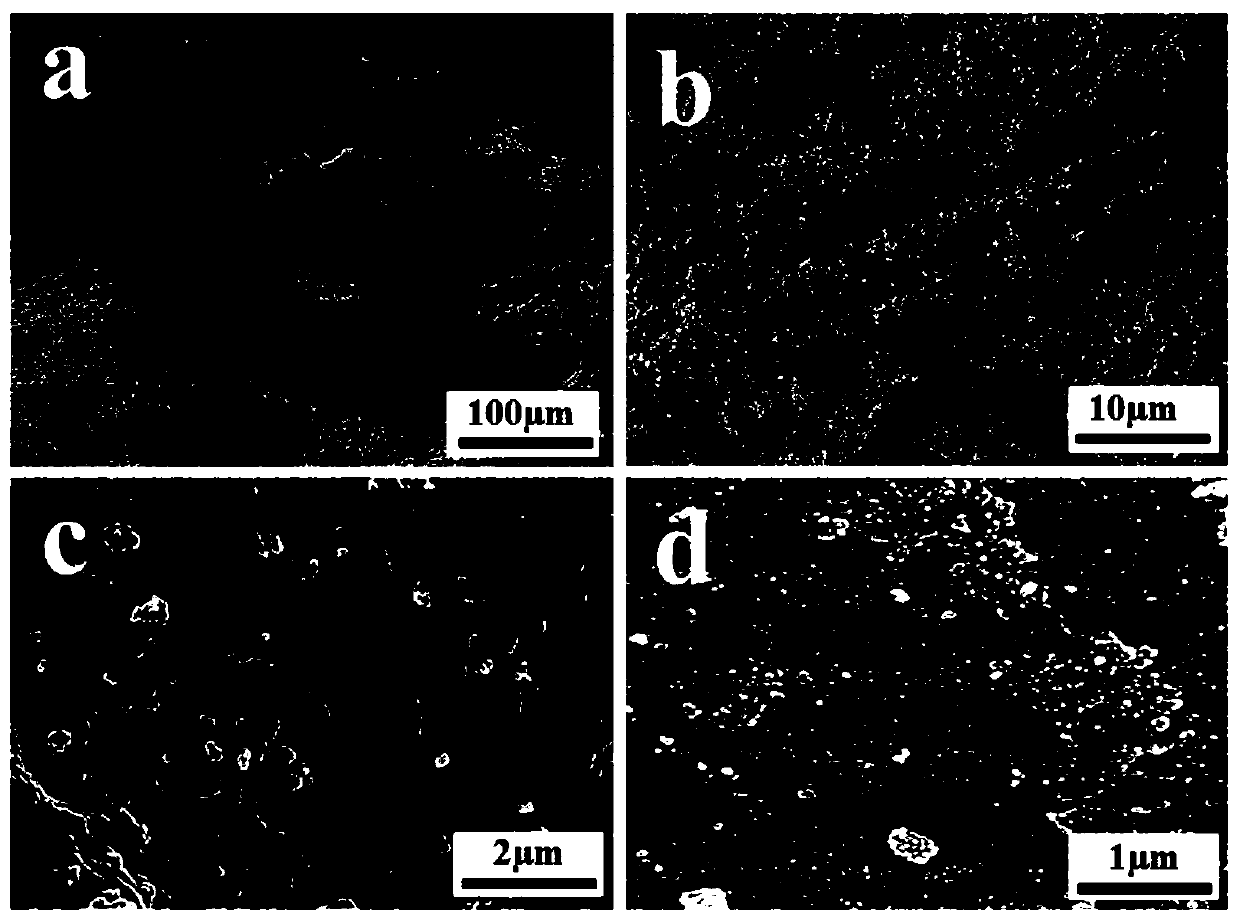

[0039] (4) the diatom plate in the Fe-TiO 2 impregnated and pulled in the gel to obtain Fe-TiO coated 2 Diatom sheets of gel films;

[0040] (5) Coating the Fe-TiO 2 The diatom plate of the gel film is dried and calcined in sequence to obtain a composite photocatalytic diatom plate;

[0041] The steps (1) and (2) are not limited by time sequence.

[0042] In the present invention, the alcohol, the retarder and the soluble titanium source are mixed to obtain the first ...

Embodiment 1

[0061] (1) At room temperature, mix 100 mL of absolute ethanol with 10 mL of acetic acid, stir magnetically for 15 minutes, and then add 5 mL of tetrabutyl titanate (TBOT) dropwise through a peristaltic pump to obtain the first mixed solution;

[0062] (2) At room temperature, mix 60mL of deionized water and 30mL of absolute ethanol, and after magnetically stirring for 15min, based on the molar amount of tetrabutyl titanate (TBOT) added in step (1), according to n(Fe) / n(Ti) is a ratio of 0.5%, 7.5mL ferric chloride solution (0.01mol / L) is added through a peristaltic pump, and then the pH value of the solution is adjusted to 2 with concentrated hydrochloric acid to obtain the second mixed solution;

[0063] (3) Slowly add the second mixed solution to the first mixed solution through a peristaltic pump, after the dropwise addition is completed, stir and react at room temperature for 1 h to form Fe-TiO 2 sol, and then carry out gelation reaction at room temperature, and form Fe-...

Embodiment 2

[0069] (1) At room temperature, mix 100 mL of absolute ethanol with 15 mL of acetic acid, stir magnetically for 15 minutes, and then add 7 mL of tetrabutyl titanate (TBOT) dropwise through a peristaltic pump to obtain the first mixed solution;

[0070] (2) At room temperature, mix 70mL of deionized water and 35mL of absolute ethanol, and after magnetically stirring for 15min, based on the molar amount of tetrabutyl titanate (TBOT) added in step (1), according to n(Fe) / n(Ti) is a ratio of 1.5%, 31.5mL ferric chloride solution (0.01mol / L) is added through a peristaltic pump, and then the pH value of the solution is adjusted to 2 with concentrated hydrochloric acid to obtain the second mixed solution;

[0071] (3) Slowly add the second mixed solution to the first mixed solution through a peristaltic pump, after the dropwise addition is completed, stir and react at room temperature for 1 h to form Fe-TiO 2 sol, and then gelatinized at room temperature to form Fe-TiO after 18 hour...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com