A Method for Preparing Large-area Periodic Structures Induced by Line Spots

A periodic structure and large-area technology, which is applied in the manufacture of microstructure devices, microstructure technology, microstructure devices, etc., can solve the problems of unfavorable large-area processing, change of film performance, and small focus spot, so as to simplify the surface processing technology, Improvement of processing efficiency and reduction of energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, a method for preparing a large-area periodic structure with line spot induction, comprising the following steps:

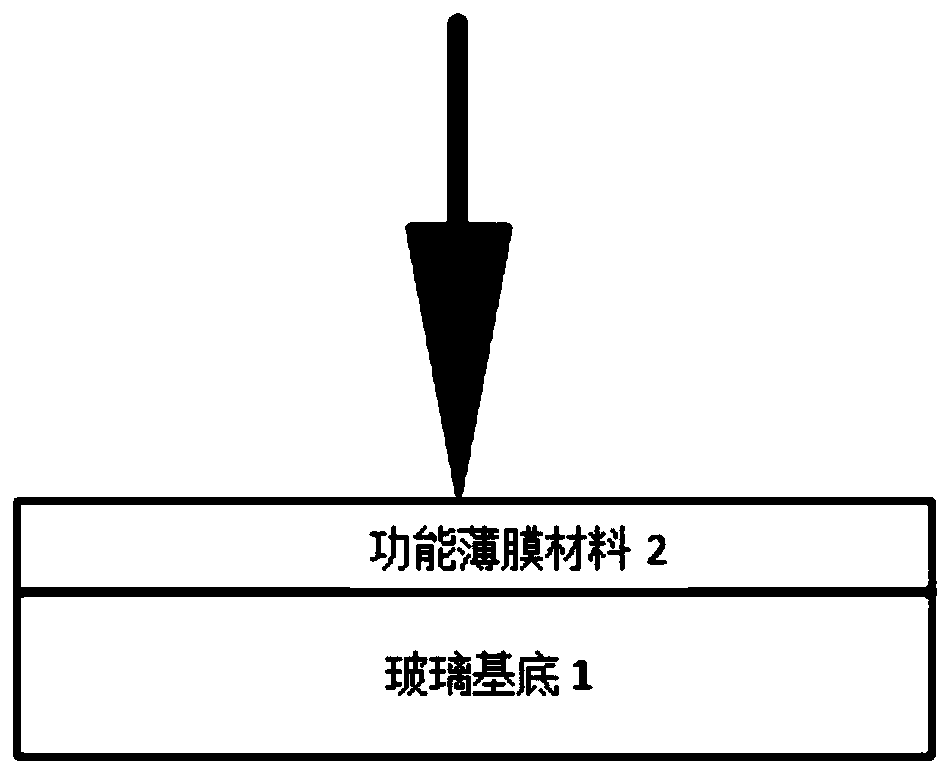

[0025] 1) Sputtering a layer of CIGS light-absorbing functional film material 2 with a thickness of 1.2 μm on the glass substrate 1;

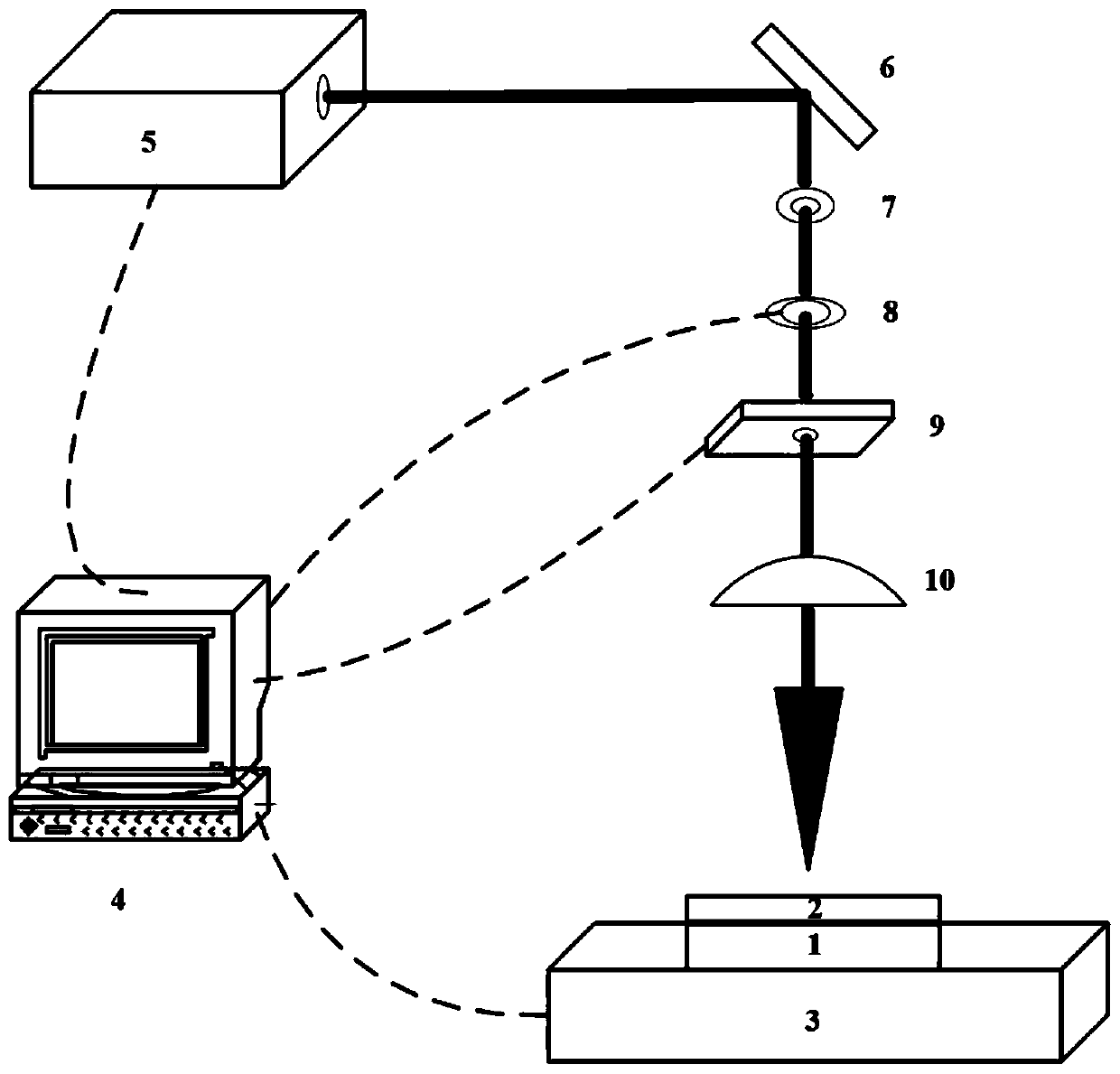

[0026] 2) Fix the glass substrate 1 sputtered with the CIGS light-absorbing functional thin film material 2 on the three-coordinate workbench 3, the three-coordinate workbench 3 cooperates with the processing optical path system, and the processing optical path system includes femtosecond laser 5, femtosecond laser 5 After being reflected by the reflector 6, the output laser light can be vertically irradiated on the CIGS light-absorbing functional thin film material 2 after passing through the aperture diaphragm 7, the attenuation plate 8, the shutter 9 and the focusing cylindrical mirror 10 in sequence. The femtosecond laser 5, The attenuation sheet 8, the shutter 9 and the three-coordinate table 3 are control...

Embodiment 2

[0030] Embodiment 2, a method for preparing a large-area periodic structure with line spot induction, comprising the following steps:

[0031] 1) Sputtering a layer of CIGS light-absorbing functional film material 2 with a thickness of 1.2 μm on the glass substrate 1;

[0032] 2) Fix the glass substrate 1 sputtered with the CIGS light-absorbing functional thin film material 2 on the three-coordinate workbench 3, the three-coordinate workbench 3 cooperates with the processing optical path system, and the processing optical path system includes femtosecond laser 5, femtosecond laser 5 After being reflected by the reflector 6, the output laser light can be vertically irradiated on the CIGS light-absorbing functional thin film material 2 after passing through the aperture diaphragm 7, the attenuation plate 8, the shutter 9 and the focusing cylindrical mirror 10 in sequence. The femtosecond laser 5, The attenuation sheet 8, the shutter 9 and the three-coordinate table 3 are control...

Embodiment 3

[0036] Embodiment 3, a method for preparing a large-area periodic structure induced by a line spot, comprising the following steps:

[0037] 1) Sputtering a layer of CIGS light-absorbing functional film material 2 with a thickness of 1.2 μm on the glass substrate 1;

[0038] 2) Fix the glass substrate 1 sputtered with the CIGS light-absorbing functional thin film material 2 on the three-coordinate workbench 3, the three-coordinate workbench 3 cooperates with the processing optical path system, and the processing optical path system includes femtosecond laser 5, femtosecond laser 5 After being reflected by the reflector 6, the output laser light can be vertically irradiated on the CIGS film 2 after passing through the aperture diaphragm 7, the attenuation sheet 8, the shutter 9 and the focusing cylindrical mirror 10. The femtosecond laser 5, the attenuation sheet 8, The shutter 9 and the three-coordinate table 3 are controlled by being connected with the computer 4;

[0039] 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com