Plastic bottle fragment label paper separating machine

A label paper and separator technology, which is applied in the field of plastic bottle flake label paper separator, can solve the problems of poor separation effect, air pollution, and incomplete separation of PVC label paper, and achieve less deformation, less air pollution, and small friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

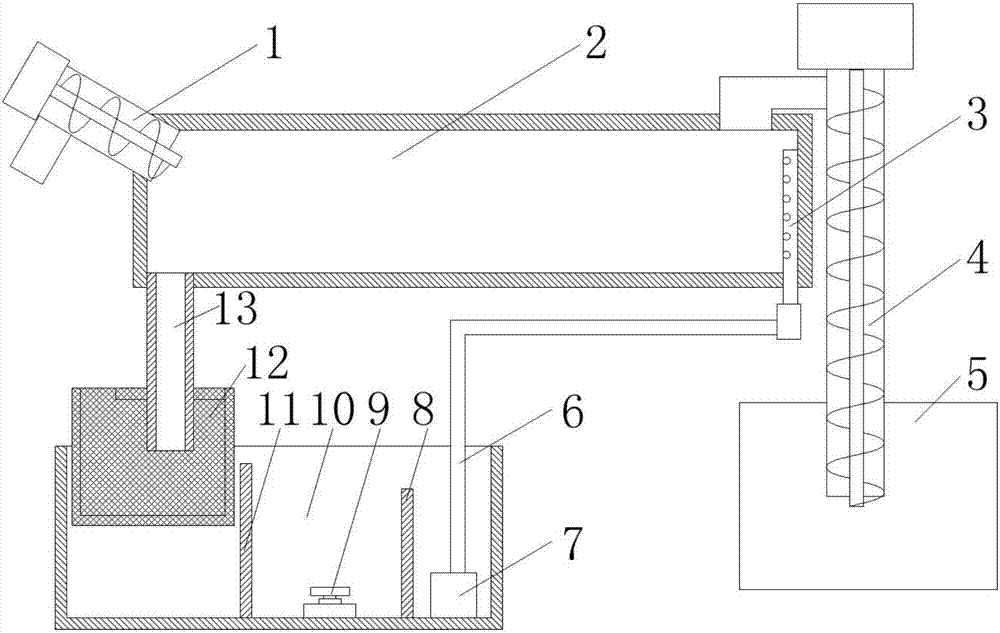

[0017] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

[0018] like figure 1 As shown, the plastic bottle flake trademark paper separator of the present invention includes a flotation box, a screw output device, a screw input device, a discharge pipe, a filter box, a water tank, a submersible pump, a water delivery pipe, a spray pipe and a feed box.

[0019] One end of the top of the flotation box is provided with a bottle flake floating outlet, and the other end of the top of the flotation box is provided with a feed port. The bottom inlet of the screw output device communicates with the bottle flake floating outlet, and the screw output device drives the screw shaft through the motor to roll out the PP bottle flakes and PE bottle flakes in the flotation tank. The top outlet of the screw input device communicates with the feed port, and the bottom inlet of the screw input device is set in the material box....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com