Processing technology for combining silica gel and metal

A treatment process, silica gel technology, applied in the field of silica gel and metal combined treatment process, can solve the problems of metal crushing, irregularity, metal scrapping, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail, should be understood that structure of the present invention is not limited to following embodiment:

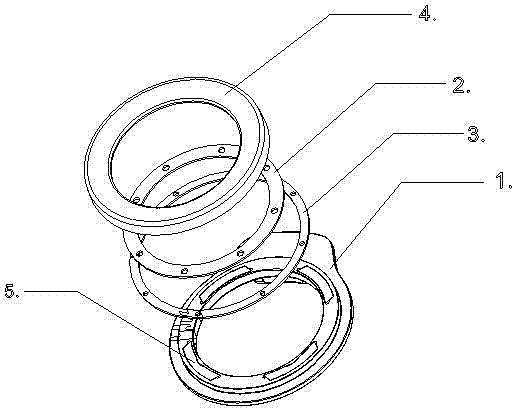

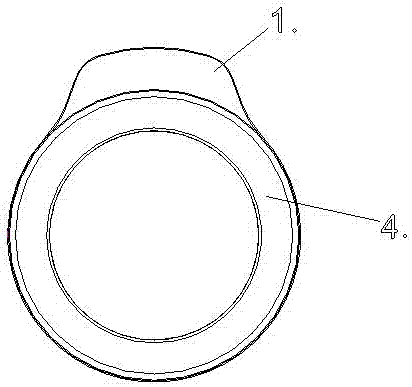

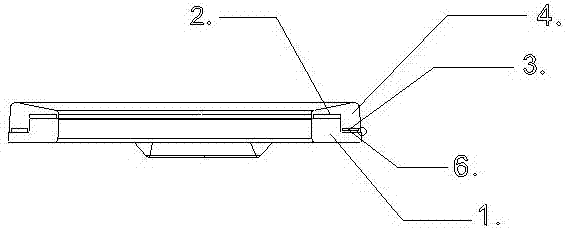

[0014] This program provides a combination treatment process of silica gel and metal, such as Figure 1-2 As shown, it includes: upper and lower molds, appearance metal parts 1, transition piece A2, transition piece B3, silica gel 4 and magnet 5, and the transition piece A2 and transition piece B3 are inner and outer annular shapes with different diameters. Transition piece 2,3 is metal material, and described magnet 5 is installed on appearance metal part 1, comprises the following steps: a, transition piece A2, transition piece B4 are marked with glue, are fixed in the lower mold by fixture, the transition of this moment Sheet A2 and transition piece B3 are concentric circles inside and outside, and the height of transition piece A2 on the inside is hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com