Rope driving automation stereoscopic warehouse storing and taking device and method capable of avoiding obstacles

A three-dimensional warehouse and access device technology, which is applied to storage devices, transportation and packaging, etc., can solve the problems of complex transportation routes, high equipment costs, and bulky equipment, and achieve the effects of high flexibility, simple composition and structure, and shortened layout cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

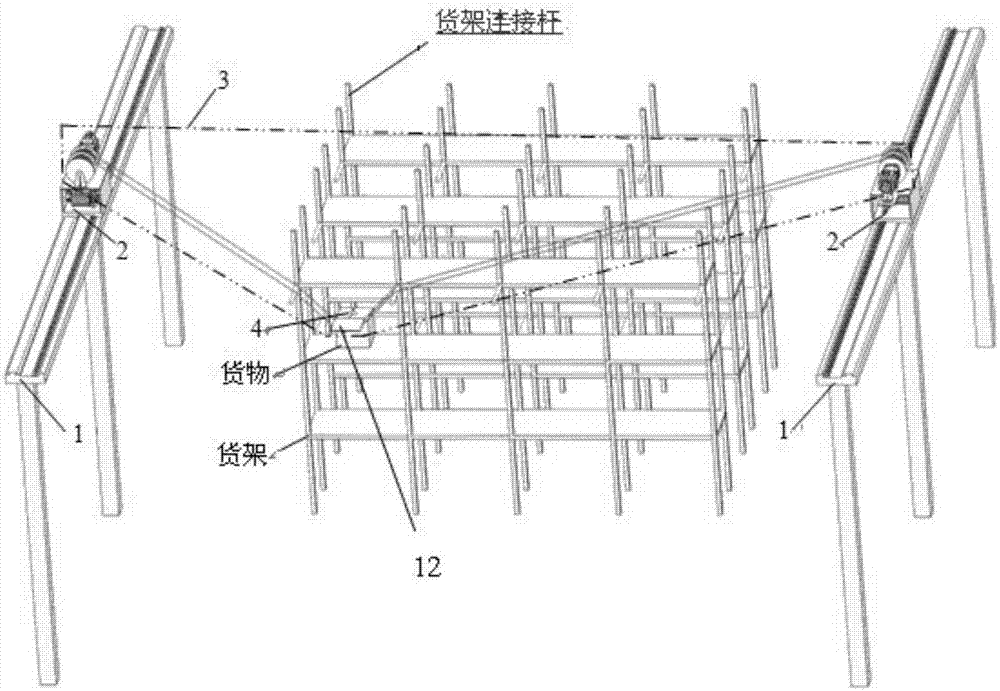

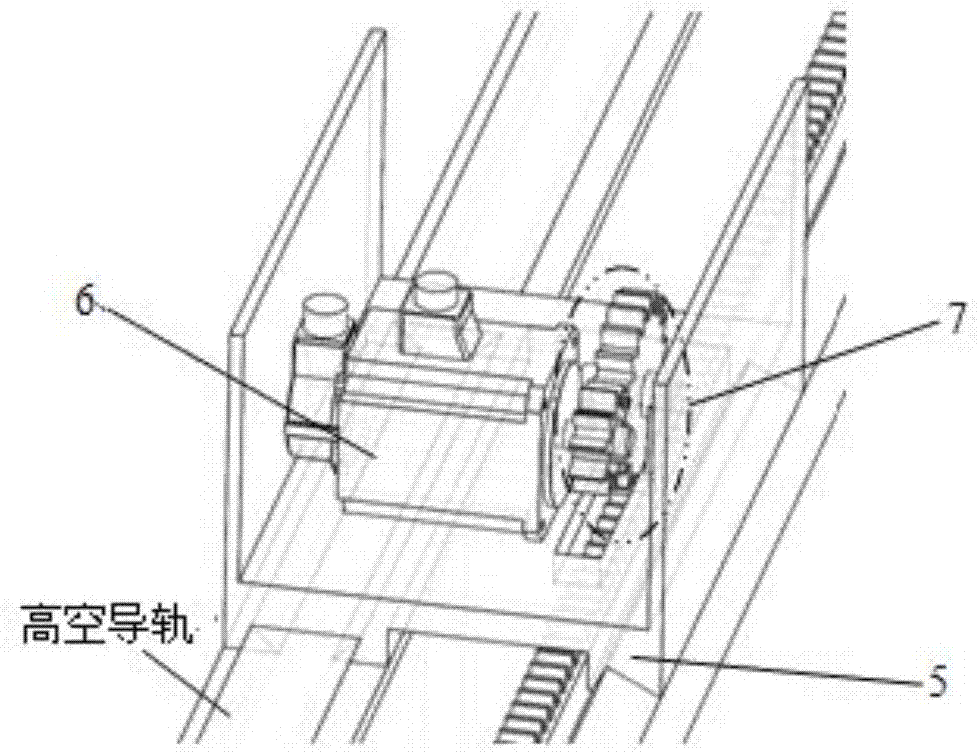

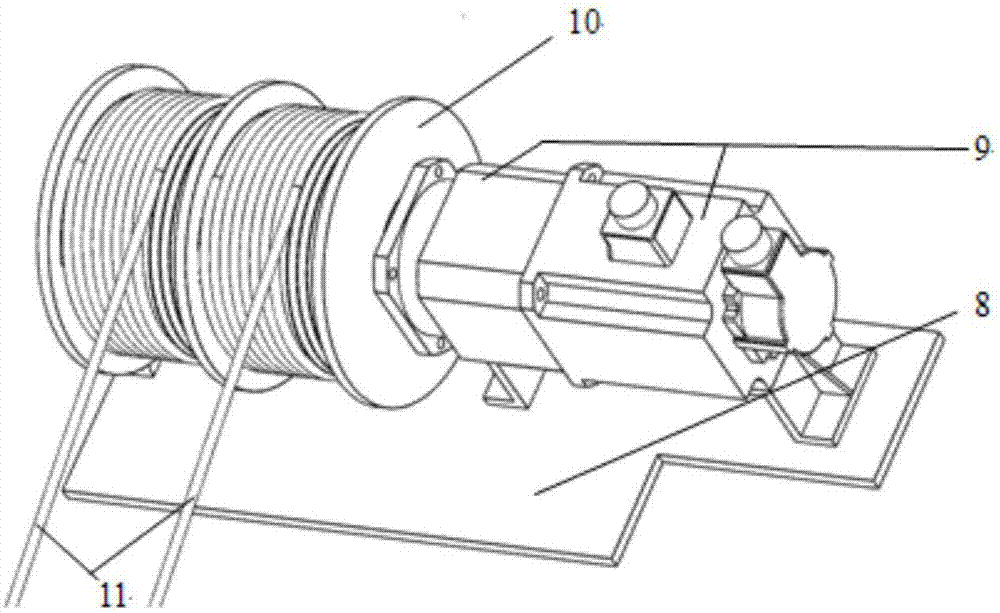

[0034] Such as figure 1 As shown, the obstacle-avoidable cable-driven automatic three-dimensional warehouse quick access device of the present invention consists of a high-altitude guide rail 1, a high-altitude mobile platform 2, a cable-driven parallel mechanism 3 and a cargo push rod 4. The two high-altitude guide rails 1 are parallel and symmetrically fixed on the left and right column groups, and the two high-altitude mobile platforms 2 move synchronously at high altitude along the left and right high-altitude guide rails 1, providing the whole device with a degree of freedom of movement along the direction of the guide rails. The bases of the two cable-out reels of the cable-driven parallel mechanism 3 are fixed on the two high-altitude mobile platforms 2, and each of the two rollers draws out two cables to pull ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com