A method for controlling a sorting device

A control method and technology of a sorting device, which are applied to conveyor control devices, transportation and packaging, mechanical conveyors, etc., can solve problems such as reduced production efficiency, stuck assembly lines, and inability to achieve high-precision functions, and achieve simple structure, The effect of preventing collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

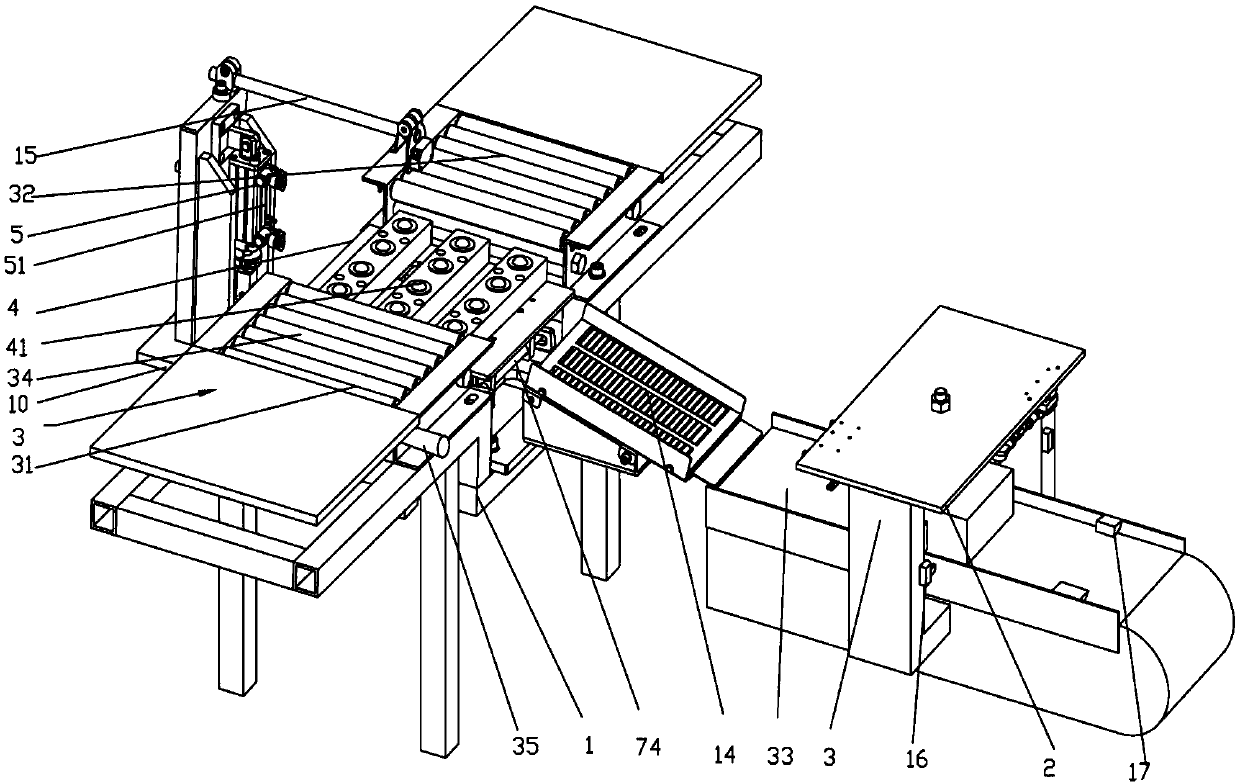

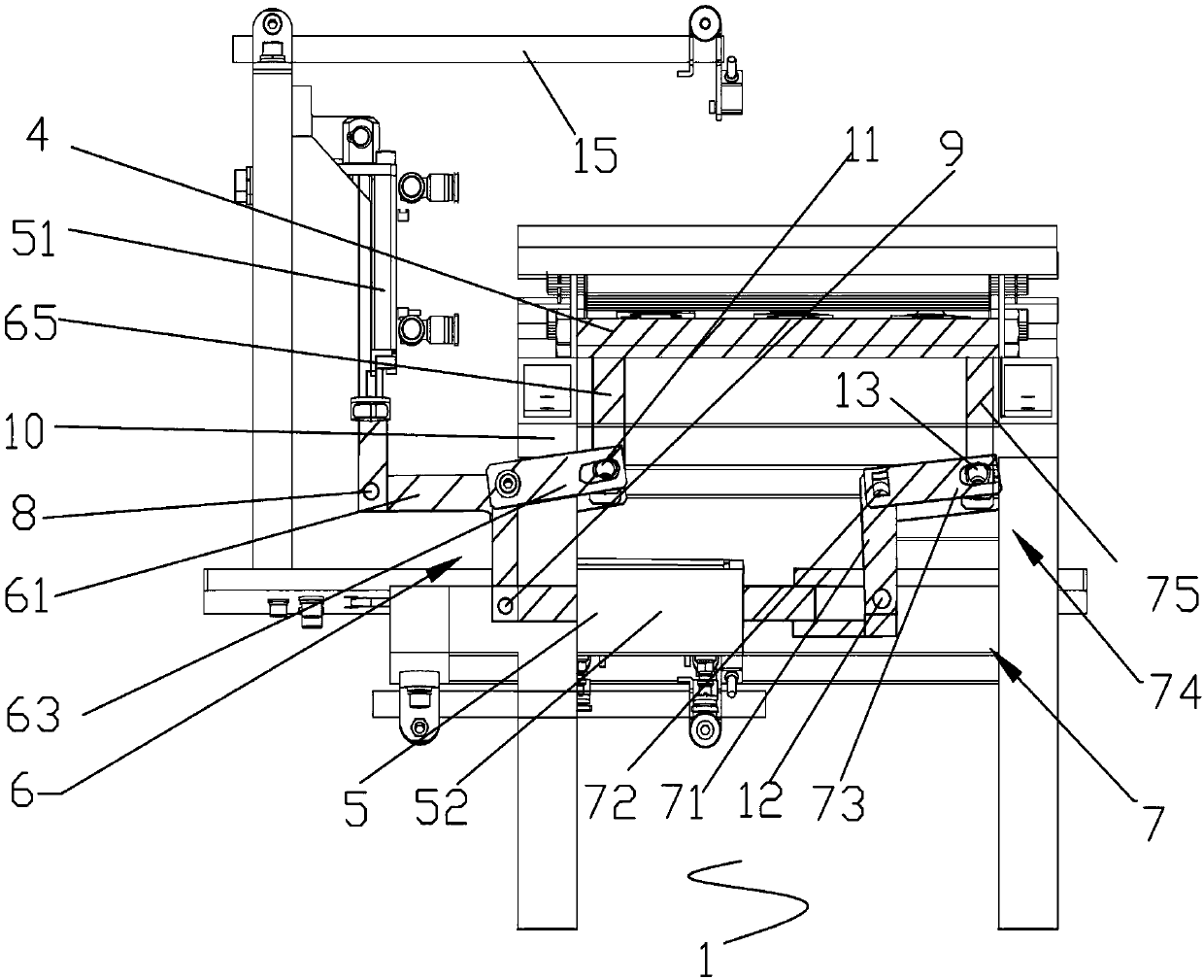

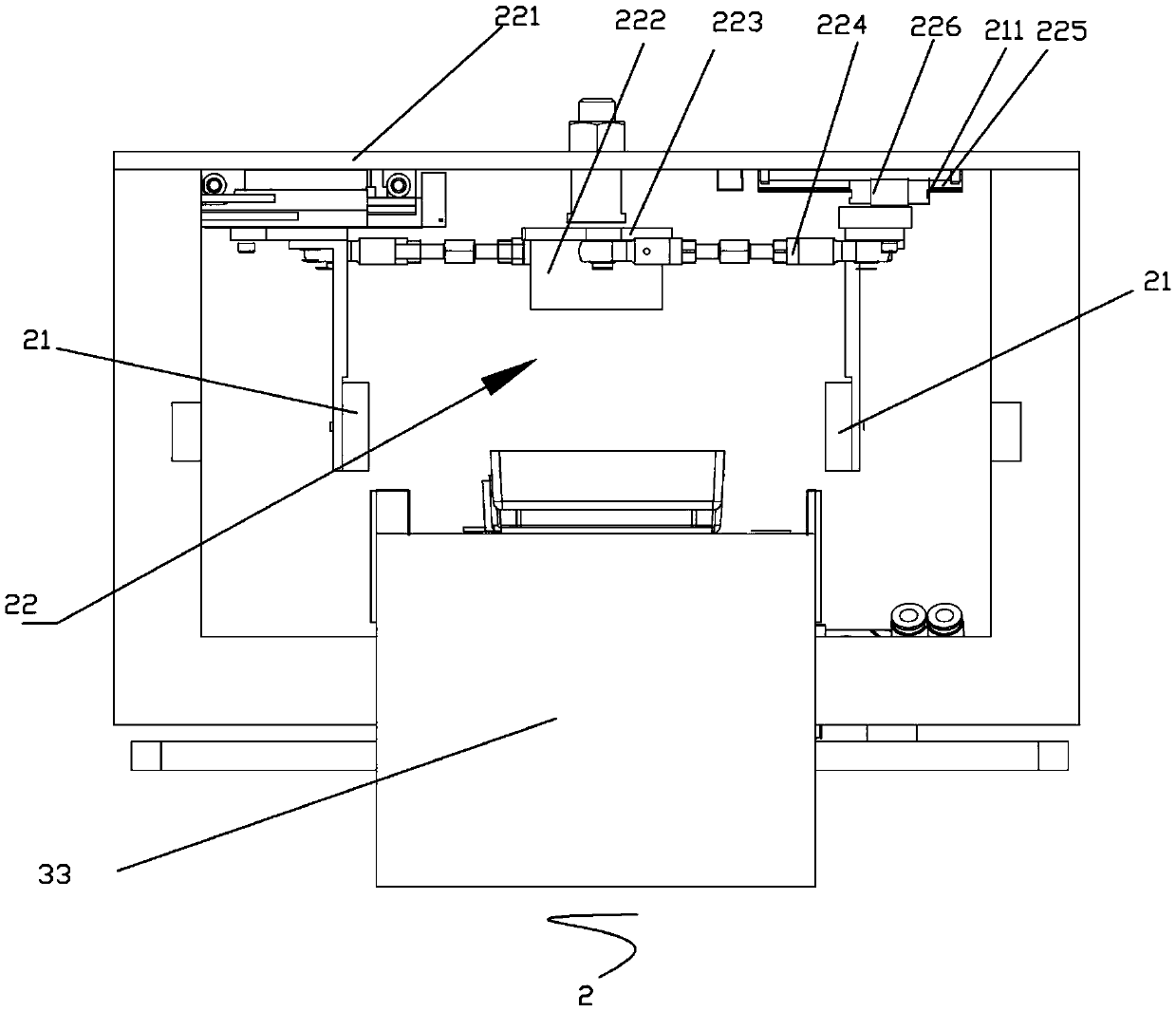

[0028] according to figure 1 , the sorting device includes a frame 10, a separation mechanism 1, a centering mechanism 2, and a conveying mechanism 3, and the separation mechanism 1 includes a movable slideway 4, a driving device 5 for driving the movable slideway 4 to lift and tilt, and the The driving device 5 includes a vertically arranged longitudinal cylinder 51, a horizontally arranged horizontal cylinder 52 connected to the output shaft of the longitudinal cylinder 51 through a first connection structure 6, and the horizontal cylinder 52 is connected to the movable slideway 4 through a second connection structure 7. The bottom end is attached.

[0029] Such as Figure 4 As shown, the first connecting structure 6 includes an "L" shaped rod 61, a first rotating sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com