Conveying structure for drill bit of electric drill

A drill bit and electric drill technology, which is applied in the field of conveying structures for electric drill bits, can solve the problems of high labor intensity, inconvenience, and consumption of many workers, and achieve the effect of reducing manual labor and energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

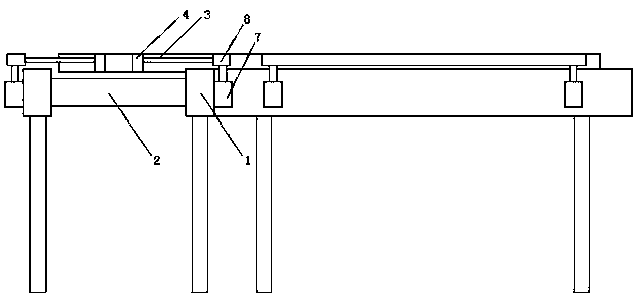

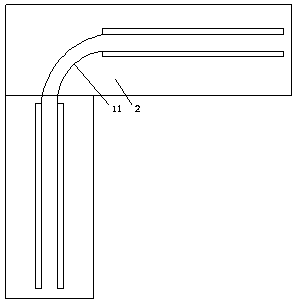

[0019] Such as figure 1 , figure 2 A delivery structure for an electric drill bit is shown, which is used to transport the drill bit of an electric tool during the processing process between different processes, including

[0020] A conveying unit, the conveying unit includes a pair of vertically distributed conveying brackets 1, each of which is equipped with a conveyor belt 2, and the conveying directions of the two conveyor belts 2 are perpendicular to each other.

[0021] A blocking unit, which includes a pair of blocking plates 4 arranged above the conveyor belt 2, the blocking plates 4 extend along the conveying direction of the conveyor belt 2, and the outer sides of the two ends of the blocking plates 4 are fixed by a The rod 3 is fixed on the conveying bracket 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com