Engineering door gluing hot-pressing production line and material distribution method thereof

A distribution method and production line technology, applied to conveyor objects, lighting and heating equipment, roller tables, etc., can solve the problem that the feeding efficiency cannot meet the processing efficiency of automatic lines, the hot pressing processing line cannot work at full load, and the surface of engineering doors is covered with film. damage and other problems, to achieve the effect of reducing the floor space of the production line, enriching the possibilities, and a good working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The technical solutions of the present invention are further described in detail below with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following.

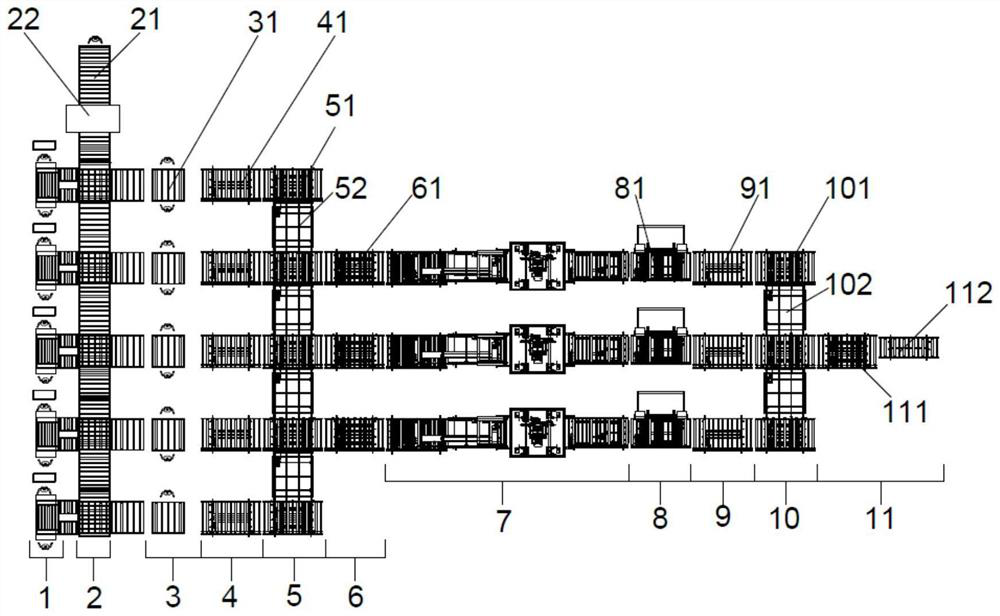

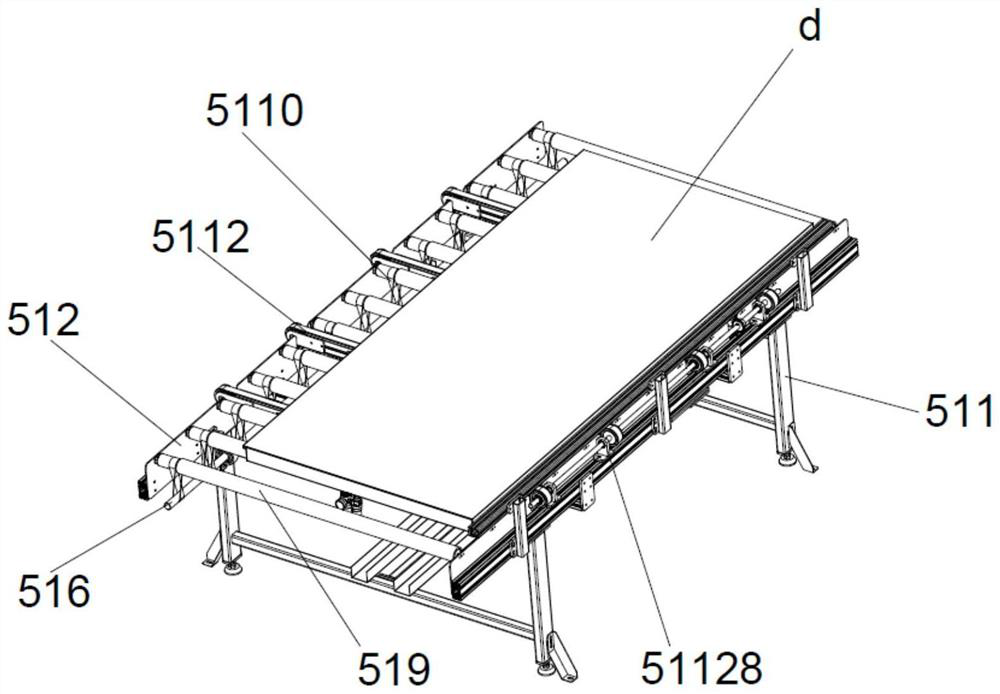

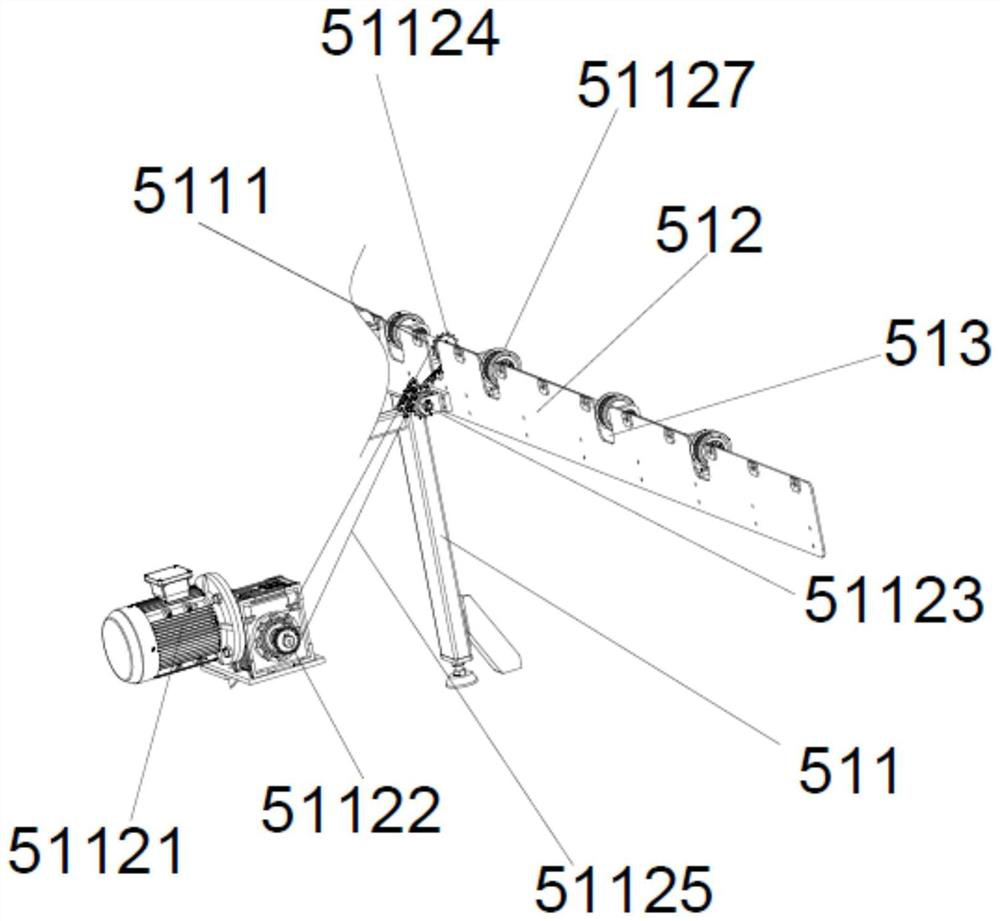

[0063] see Figure 1 to Figure 10 , in the embodiment of the present invention, an engineering door gluing hot pressing production line is provided, which includes a gluing line 2 for applying gluing to the material and a plurality of hot pressing processing lines 7 for hot pressing the material after gluing, The gluing line 2 includes an automatic gluing conveyor line 21 for conveying materials and a gluing equipment 22 for applying gluing to the materials. One side of the gluing line 2 is provided with a plurality of core material filling stations 1. The other side of the gluing line 2 is provided with a preliminary welding station 3 corresponding to the core material filling station 1 one-to-one. Between the preliminary welding station 3 and the hot-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com