A kind of preparation method of high-purity Jinggang mycamine

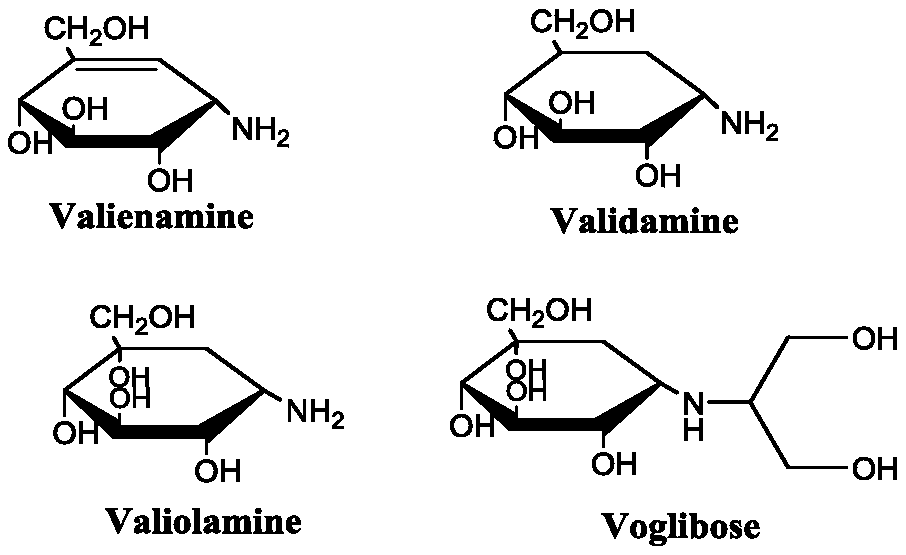

A technology of Jinggangmycolamine and Jinggangmycolamine, which is applied in the field of new preparation of high-quality Jinggangmycolamine, can solve the problems of inability to large-scale production and huge separation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

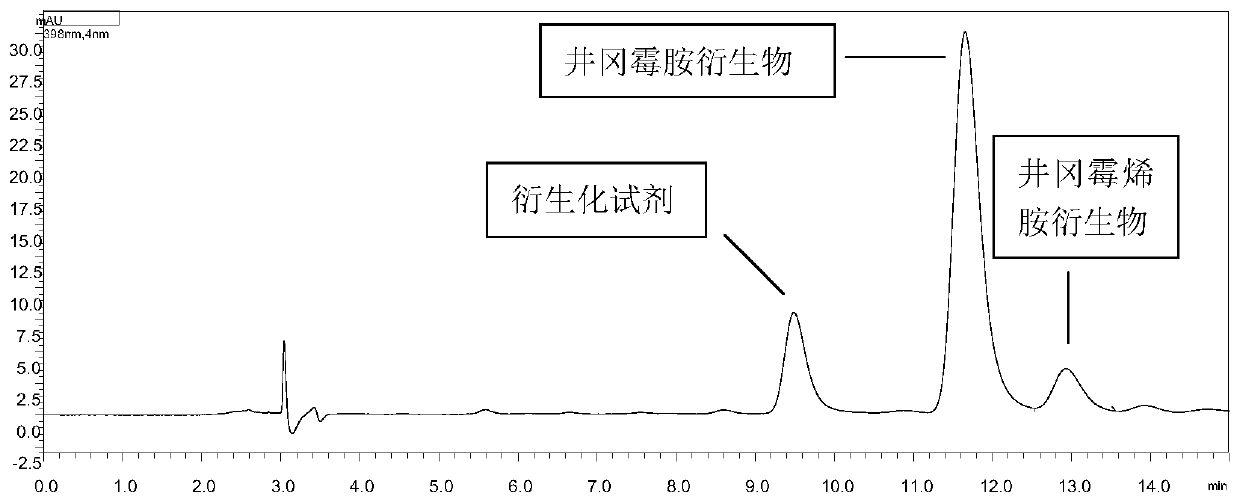

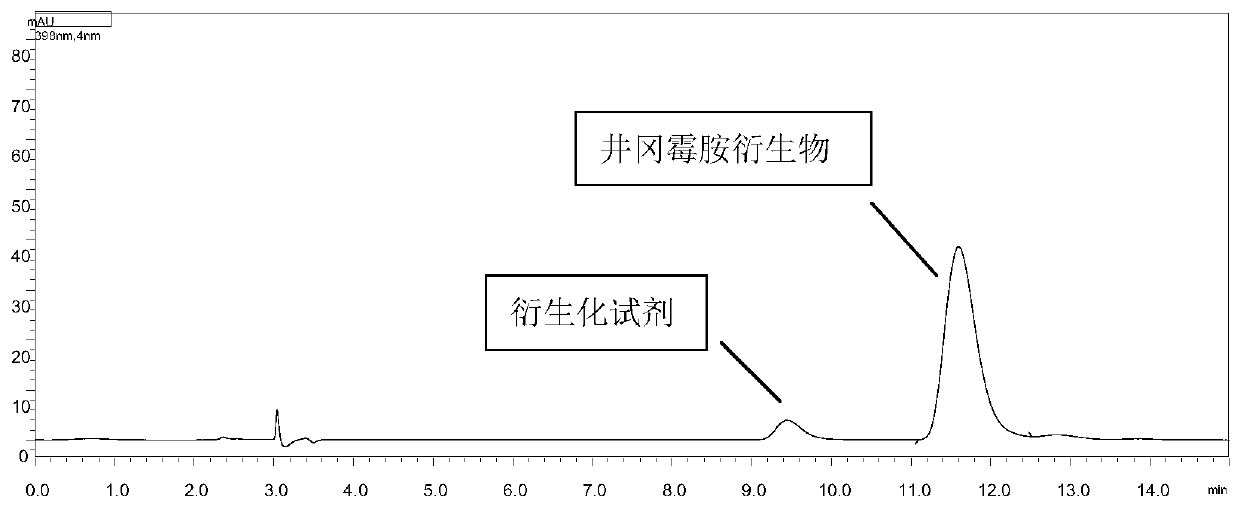

Image

Examples

Embodiment 1

[0021] (1) Add 100 g mycoylidene A, 80 g NBS and 500 mL deionized water into a 1000 mL flask, and stir and react at 25° C. for 4 h. After the reactant was diluted 10 times with water, the ion exchange column (D113, Hangzhou Zhengguang Resin Co., Ltd., 1500mL, NH 4 + type), washed with 5000mL deionized water, and then eluted with 4500mL of 0.5mol / L ammonia water, collected the mixture of Jinggangmycin and Jinggangmycin, concentrated to dryness under reduced pressure, and obtained 45.2g sample.

[0022] (2) Dissolve the mixture in 500mL of water and place it in a 1000-mL hydrogenation reactor. At the same time, put 5g of supported Pd catalyst (Konna New Materials (Hangzhou) Co., Ltd.), add hydrogen to a pressure of 5MPa, and react at 50°C 4h. After the reaction finishes, filter off the solid, dilute 10 times with deionized water and go to the ion exchange column (same as above), wash with 5000mL deionized water, then elute with 4500mL0.5mol / L ammonia water, collect the mixture...

Embodiment 2

[0024] (1) Add different amounts of mycoylidene amine A, 80 g of NBS and 500 mL of deionized water into a 1000 mL flask, and stir and react at 25° C. for 4 h. After the reactant was diluted 10 times with water, it was put on an ion exchange column (D113, Hangzhou Zhengguang Resin Co., Ltd., 1500mL, NH4+ type), washed with 5000mL deionized water, and then eluted with 4500mL 0.5mol / L ammonia water to collect Jinggangmycin The mixture of amine and mycoamine was concentrated to dryness under reduced pressure to obtain a 45.2 g sample. (2) Dissolve the mixture in 500mL of water and place it in a 1000-mL hydrogenation reactor. At the same time, put 5g of supported Pd catalyst (Konna New Materials (Hangzhou) Co., Ltd.), add hydrogen to a pressure of 5MPa, and react at 50°C 4h. After the reaction, filter off the solid, dilute it 10 times with deionized water and put it on the ion exchange column (same as above), wash with 5000mL deionized water, and then elute with 4500mL 0.5mol / L am...

Embodiment 3

[0028] According to the method of step (1) of Example 1, a mixture of Jinggang mycylamine and Jinggang mycamine was obtained, and the amount of hydrogenation reaction solvent was optimized. 45g of the above-mentioned mixture plus different amounts of water (100, 250, 500, 1000, 1500) were dissolved and placed in a hydrogenation reactor, and 5g of loaded Pd catalyst (Konna New Materials (Hangzhou) Co., Ltd.) was added at the same time. To a pressure of 5MPa, react at 50°C for 4h. After the reaction, filter off the solid, dilute it 10 times with deionized water and put it on the ion exchange column (same as above), wash with 5000mL deionized water, and then elute with 4500mL 0.5mol / L ammonia water to collect Jinggang mycamine and Jinggang mycamine The mixture of amines was concentrated under reduced pressure and dried in vacuum (45°C) to obtain a sample of Jinggangmycin, which was detected by HPLC. The specific results are shown in the following table:

[0029] Solven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com