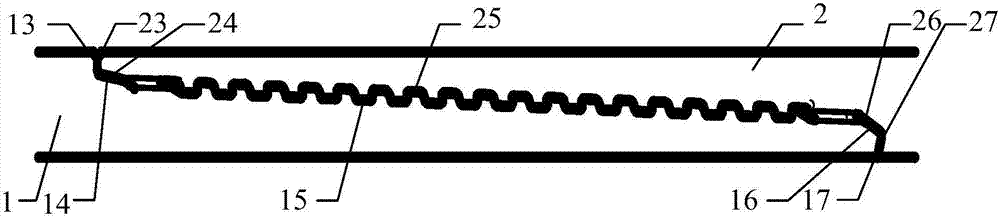

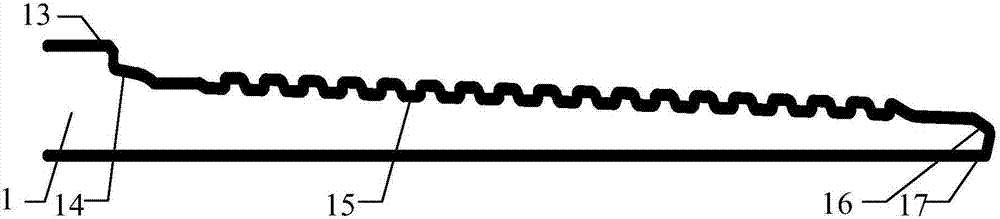

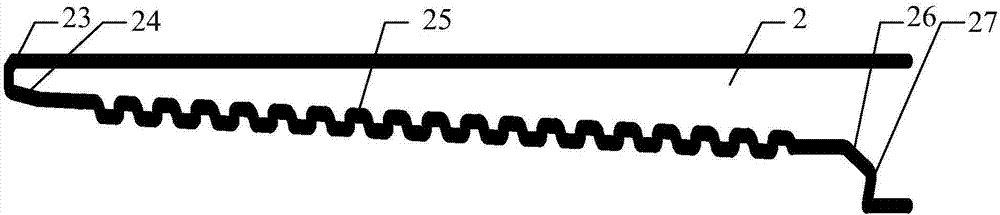

Dual-stage sealed threaded joint

A threaded joint and external sealing technology, which is applied in the direction of drilling equipment, earthwork drilling, drill pipe, etc., can solve the problems that cannot meet the requirements of 100% pipe gas sealing performance, and achieve the effect of ensuring the annular space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] Selection specifications: The outer diameter of the oil well pipe is φ88.9mm, the wall thickness is 9.52mm, and the parameters of the threaded joint (the outer diameter and wall thickness data of the male and female joints are the same) are as follows:

[0068] The inner diameter is 69.86mm, the thread pitch is 4.233mm, the thread taper is 1:16, and the first outer and inner sealing surface angle is 9°(θ 11 , θ 21 ), the first outer and inner torque shoulder angle face angle is 90°(θ 12 , θ 22 ), the angle of the second outer and inner sealing surfaces is 30°(θ 13 , θ 23 ), the angle of the second outer and inner torque shoulders is 75°(θ 14 , θ 24 ).

[0069] Implementation effect: the tensile efficiency of the joint reaches 58% of the pipe body; the compression efficiency is equivalent to 30% of the pipe body; under the condition of gas medium, the internal pressure value of the joint seal exceeds 100% of the API pipe internal pressure yield strength; for the jo...

Embodiment 2

[0071] Selection specifications: the outer diameter is φ177.8mm, the wall thickness is 10.36mm, and the parameters of the threaded joint (the outer diameter and wall thickness data of the male and female joints are the same) are as follows:

[0072] The parameters of the joint are as follows: the inner diameter is 157.08mm, the pitch is 5.08mm, the thread taper is 1:16, and the angle of the first outer and inner sealing surfaces is 9°(θ 11 , θ 21 ), the angle of the first outer and inner torque shoulders is 90°(θ 12 , θ 22 ), the angle of the second outer and inner sealing surfaces is 21°(θ 13 , θ 23 ), the second outer and inner torque shoulder surface 75°(θ 14 , θ 24 ).

[0073] Implementation effect: the tensile efficiency of the joint reaches 53% of the pipe body; the compression efficiency is equivalent to 30% of the pipe body; under the condition of gas medium, the internal pressure value of the joint seal exceeds 100% of the API pipe internal pressure yield streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com