Drying device of cotton cleaner

The technology of drying device and flower cleaning machine is applied in the directions of drying, drying machine, drying gas arrangement, etc., which can solve the problems of high drying temperature, high cost, long drying time, etc., and achieves accelerated drying speed, The effect of improving use efficiency and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

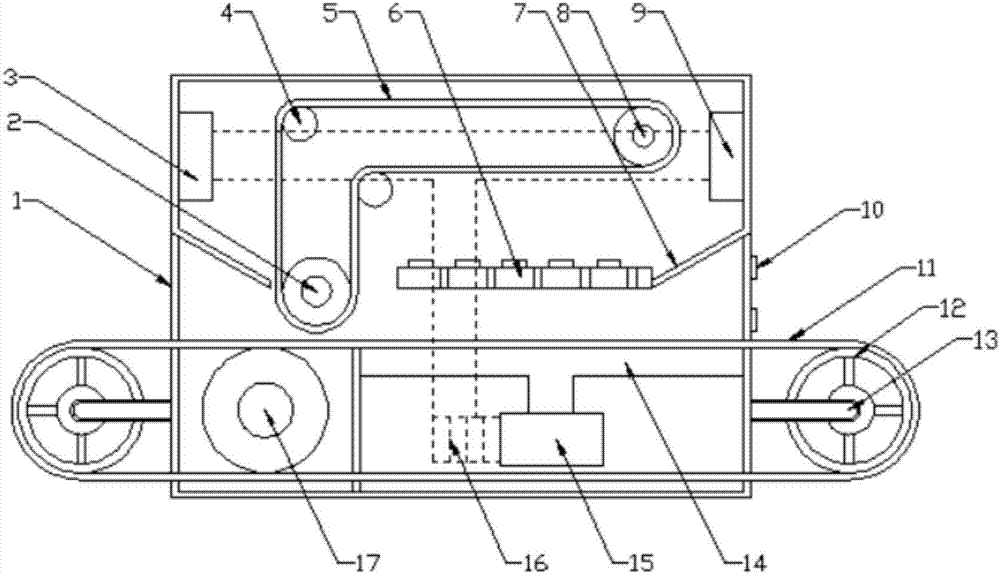

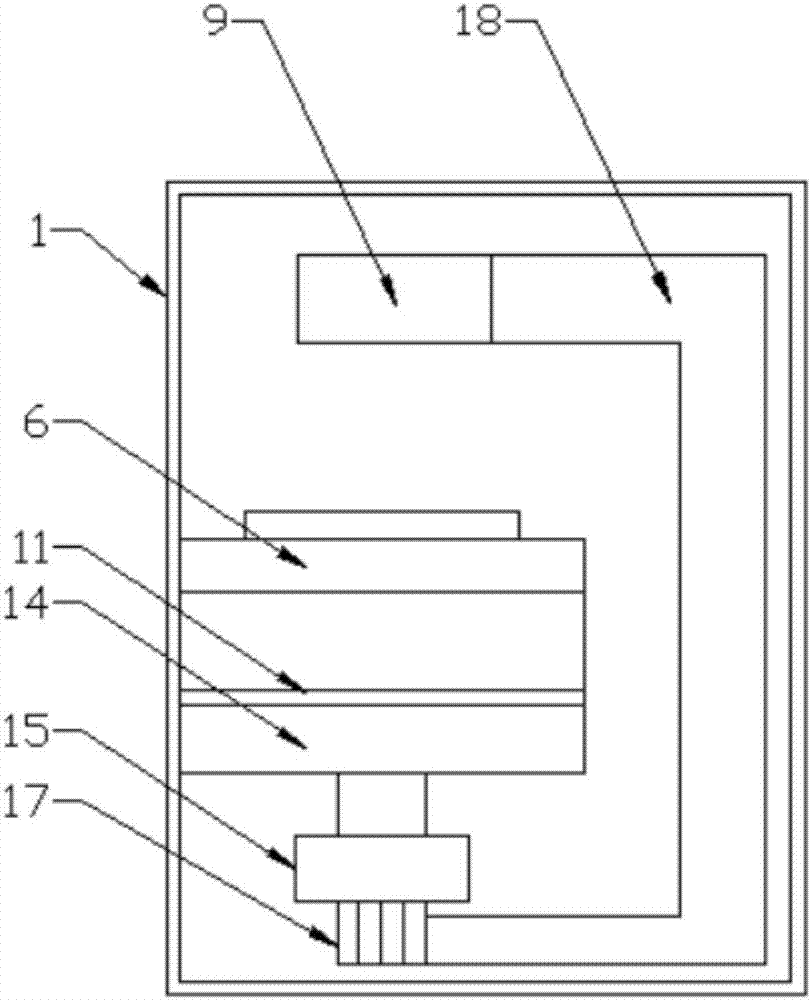

[0017] Such as Figure 1-2 As shown, a drying device of a cleaning machine includes a housing 1, and the two ends of the housing 1 are respectively provided with an inlet and an outlet. The cotton enters the drying device from the inlet, and the cotton enters the dryer from the outlet. Send out the drying device, one end of the feed port and the discharge port is provided with a sloping plate 7, the slant plate 7 is used to prevent the discharge of hot air and reduce energy loss, and the bottom of the feed port and the discharge port is provided with a conveyor belt 11, The conveyor belt 11 moves the cotton through the drying device. Both ends of the conveyor belt 11 are provided with rollers 12. The conveyor belt 11 moves along the rollers 12. Bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com