A measuring device and a measuring method for the thickness and the optical constants of ultrathin film

A technology of optical constants and ultra-thin films, which is used in measurement devices, optical devices, material analysis by optical means, etc., to achieve the effect of reducing multiplicity, high measurement accuracy, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention should not be limited thereby.

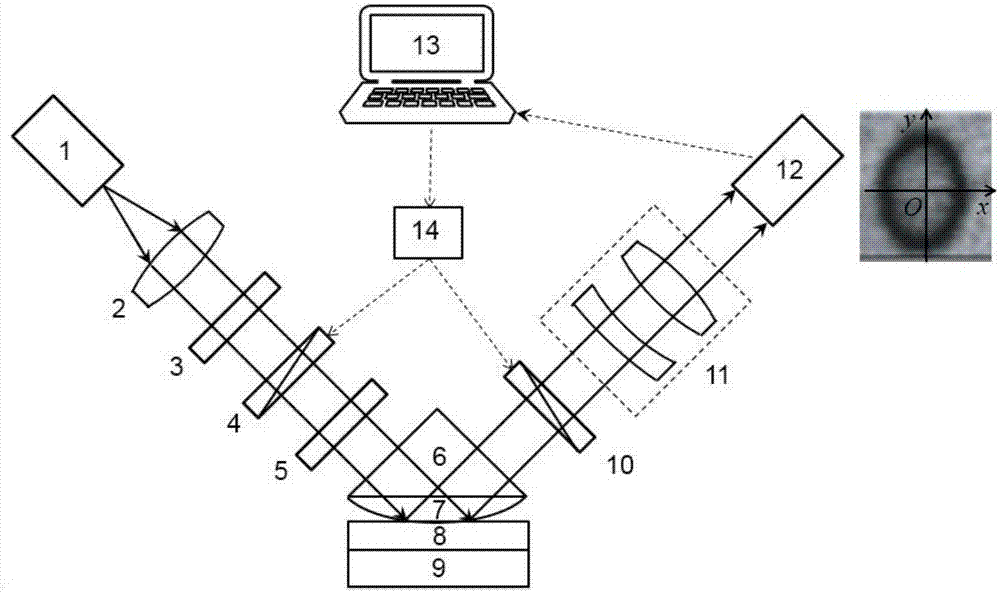

[0028] see first figure 1 , figure 1 It is a block diagram of a measuring device for ultra-thin film thickness and optical constants of the present invention, as can be seen from the figure, the measuring device for ultra-thin film thickness and optical constants of the present invention includes a laser 1, and along the laser output direction of the laser 1 is a beam expander in turn 2. A right-angled plane of 1 / 4 wave plate 3, polarizer 4, compensator 5 and right-angled prism 6, the hypotenuse of this right-angled prism 6 is connected to the plane of plano-convex spherical lens 7 by refractive index matching liquid, this plane The apex of the convex surface of the convex spherical lens 7 is in contact with the film sample 8 to be measured on the glass substrate 9, and al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com