Automated logistics system using triggering and forwarding device

A forwarding device and logistics system technology, applied in logistics, collaborative operation devices, data processing applications, etc., can solve problems such as computer logic analysis, judgment difficulty, etc., and achieve the effect of reducing environmental requirements, simple software programming, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

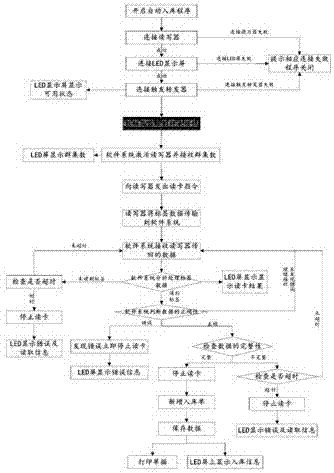

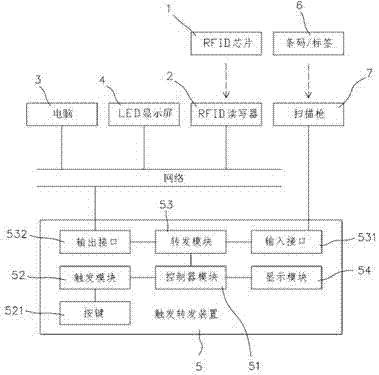

[0059] Embodiment 1, the application of the trigger forwarding device in the storage automation scene:

[0060] The triggering and forwarding device 5 is applied in the storage automation scene, and according to the actual needs of the business, the character information of the button cluster of the triggering and forwarding device is artificially assigned. Each button 521 respectively represents the number of clusters that need to be stored in the warehouse (cluster: is a concept of a collection, that is, a certain number of multiple containers that need to be stored in the warehouse are given a same cluster number, that is: these containers with the same cluster number belong to a cluster). The human brain judges which button on the trigger forwarding device 5 should be pressed according to the actual situation of the storage, and forwards the judgment result of the human brain to the software system, and at the same time, allows other automation equipment to enter the worki...

Embodiment 2

[0065] Embodiment 2, the application of the trigger forwarding device in the scene of empty container automatic outbound:

[0066] The triggering and forwarding device 5 is applied in the scene of automatic outbound of empty containers. According to the actual needs of the business, the buttons 521 of the triggering and forwarding device 5 are artificially given character information such as "reread", "cancel", and "confirm". And use the USB interface of the trigger forwarding device 5 to connect the scanning gun 7, and upload the information of the scanned barcode 6 to the software system through the device. These information may be some parameters, document numbers, or logic judgment basis required by the software system. , by comparing these logics with the data actually read by the RFID reader-writer 2, an accurate logical judgment can be obtained.

[0067] The specific operation is as follows:

[0068] The outbound personnel use the external scanning gun 7 on the trigger...

Embodiment 3

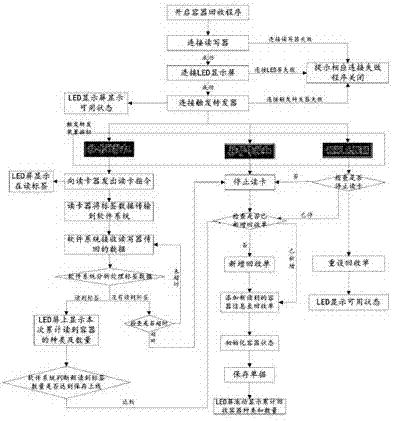

[0070] Example 3, the application in the scene of automatic recycling of empty containers in the field of logistics:

[0071] The triggering and forwarding device 5 is applied in the scene of automatic recycling of empty containers. According to the actual needs of the business, the buttons 521 of the triggering and forwarding device 5 are given character information such as "start", "pause" and "finish". According to the actual situation of empty container recycling, the human judges whether it is necessary to trigger the button on the device, and forwards the human instruction to the software system. After receiving the instruction, the software system directly starts or stops other automation equipment without complex logic judgment ( The RFID reader 2 reads the card, and the LED display 4 displays the relevant process). In this scenario, the trigger forwarding device 5 simply forwards the instruction of the person to the relevant software system.

[0072] The specific ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com