Intelligent production management system and method for prefabricated buildings

A management system and intelligent production technology, applied in data processing applications, instruments, calculations, etc., can solve complex manufacturing processes, difficult to achieve production plans, and various problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

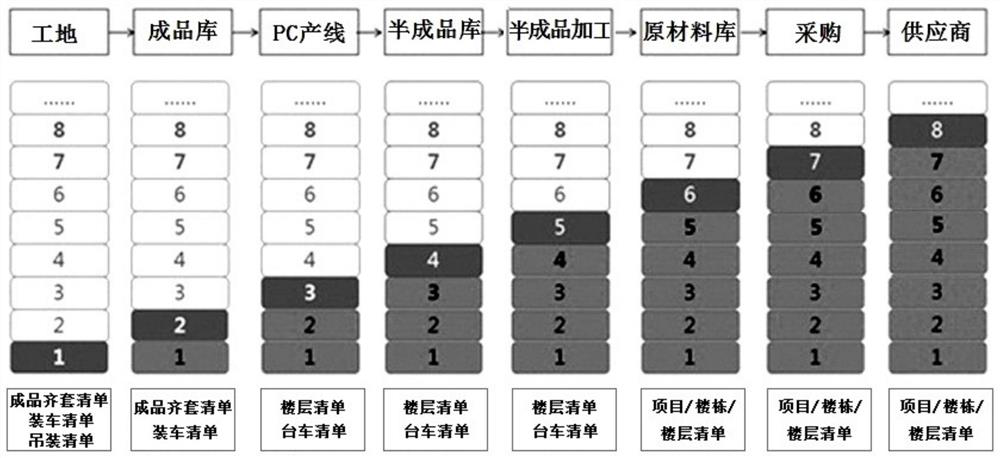

[0104] see figure 2 The shown embodiment 1: the intelligent production management system of the prefabricated building of the present invention is applied to the self-driven plan of the concrete building, and its PC production line module, concrete semi-finished product warehouse module, and concrete semi-finished product processing module are combined to maintain the same floor unit module group, but other system structures, information transmission and automatic triggering methods are not the same as figure 1 Are the same.

Embodiment 2

[0105] see image 3 The shown embodiment 2: the intelligent production management system of the prefabricated building of the present invention is applied to the self-driving plan of the building of the steel bar, and its system structure, information sending and automatic triggering method are the same as figure 1 Are the same.

Embodiment 3

[0106] see Figure 4 The shown embodiment 3: the intelligent production management system of the prefabricated building of the present invention applies the building self-driven planning diagram of PC accessories, and its PC accessories semi-finished product library module and PC accessories complete set, that is, the PC accessories semi-finished product processing module is combined to maintain the same The module group of the layer unit, its procurement module and the PC accessory supplier module are combined into a module group that maintains the same layer unit, and other system structures, information sending and automatic triggering methods are the same as figure 1 Are the same.

[0107] It should also be noted that: Figure 4 In the previous module group consisting of PC accessories semi-finished product library module and PC accessories, the delivery information of the complete set of modules will automatically trigger the PC accessories raw material library module to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com