Smashing device of corn harvester

A corn harvester and crushing device technology, applied to harvesters, agricultural machinery and implements, cutters, etc., can solve the problems of large size and troublesome use, and achieve the effects of small size, flexible operation and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

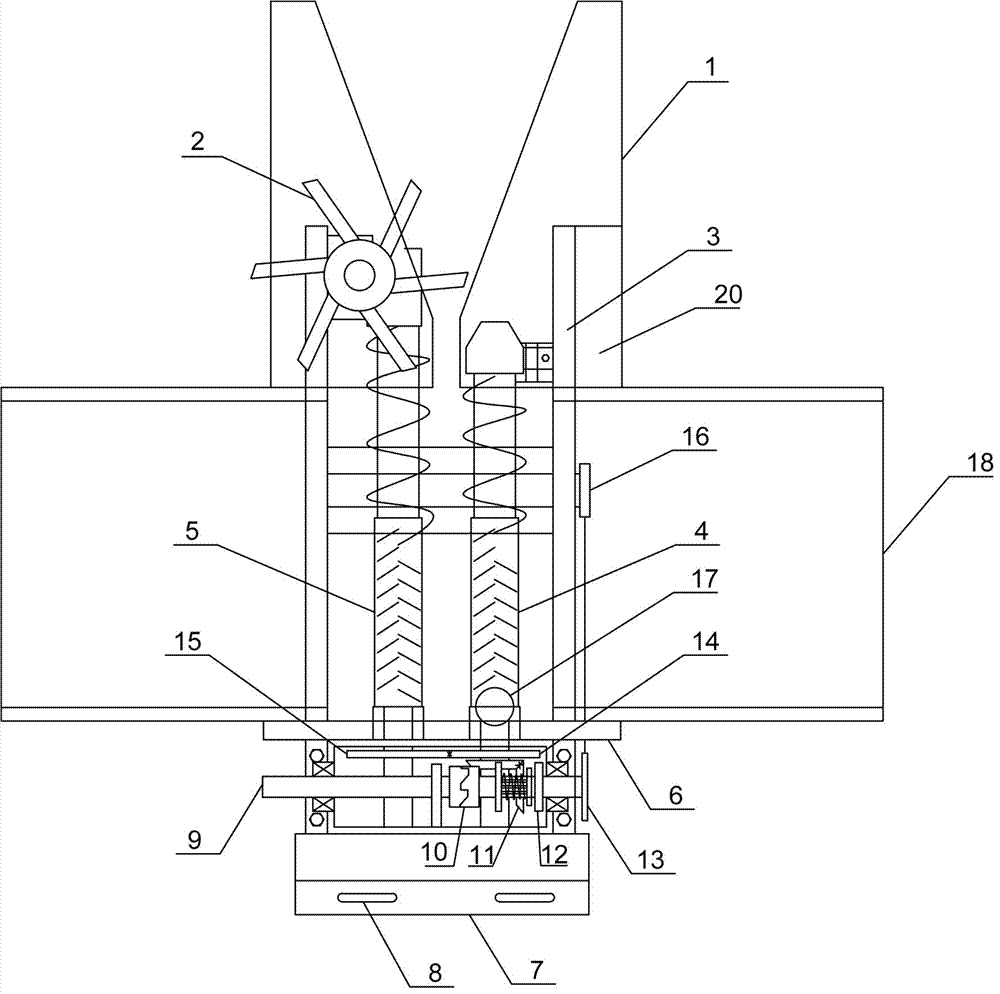

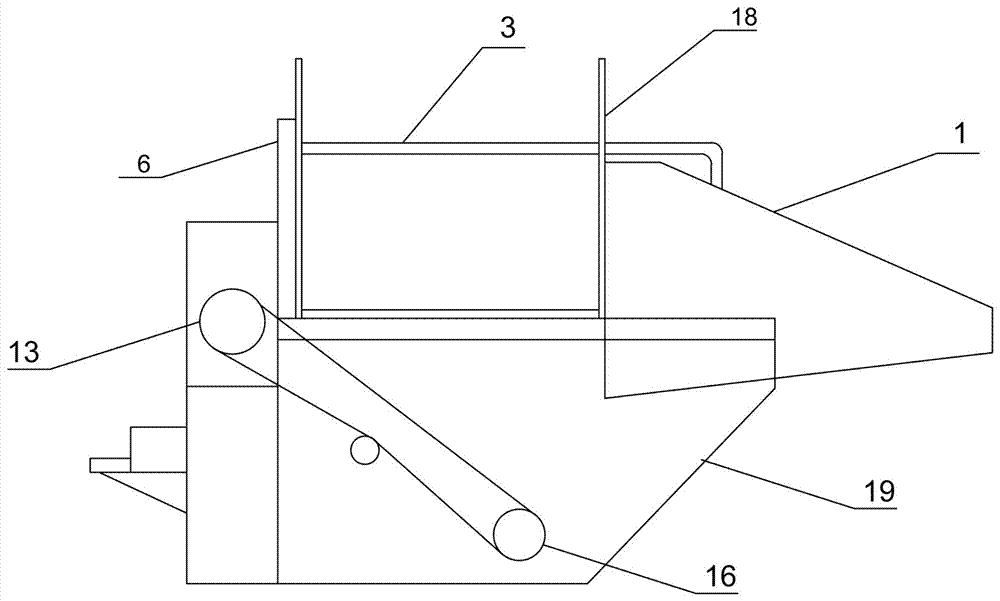

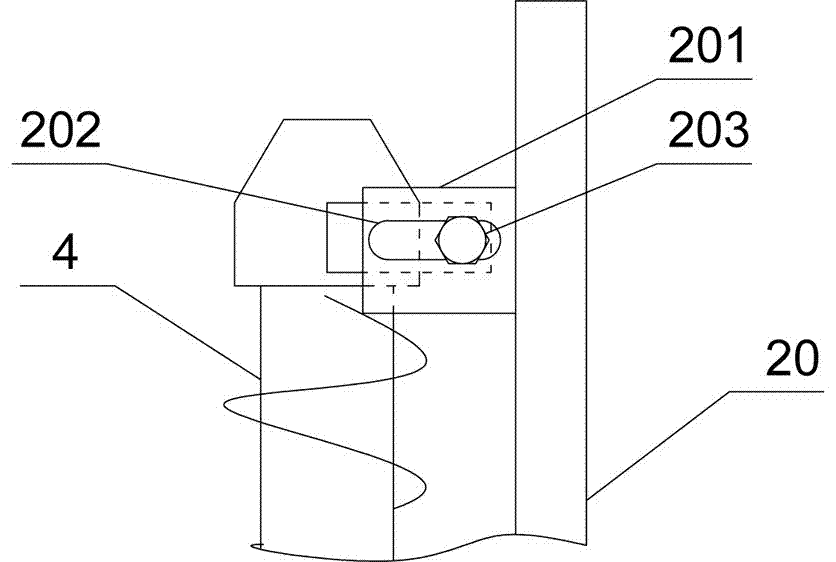

[0016] Such as Figure 1-Figure 4 As shown, the present invention provides a corn harvester, including a crushing device, an ear harvesting device, a scion device and a transmission device. The transmission device includes a gear box, in which a main shaft 9, a transmission shaft, a bevel gear 11, a first gear 12, a second gear 14, a third gear 15 and a fourth gear are set, and the first sprocket 13 is set on the outer wall of the gear box One end of the main shaft 9 is connected with the power unit of the tractor, the other end of the main shaft 9 is provided with a clutch 10, a first gear 12 and a first sprocket 13, the transmission shaft is arranged directly below the main shaft 9, and the transmission shaft is provided with the first gear 12 The fourth gear meshed, the bevel gear 11 includes a first bevel gear and a second bevel gear, the fourth gear meshes with the first bevel gear, the first bevel gear meshes with the second bevel gear, and the second bevel gear meshes w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com