Energy-saving and environment-friendly sulfur removal machine for thermal power plant

A thermal power plant, energy saving and environmental protection technology, applied in mixers, mixers with rotary stirring devices, gas treatment and other directions, can solve the problems of high energy consumption and insufficient chemical reaction, and achieve the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

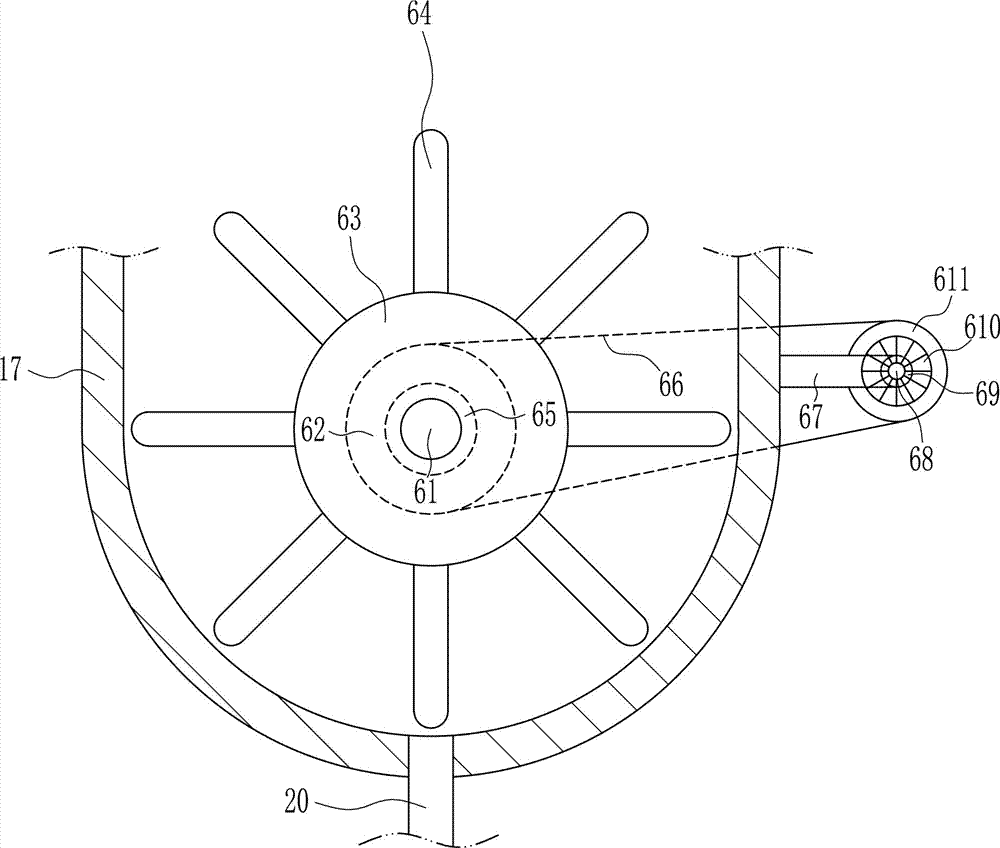

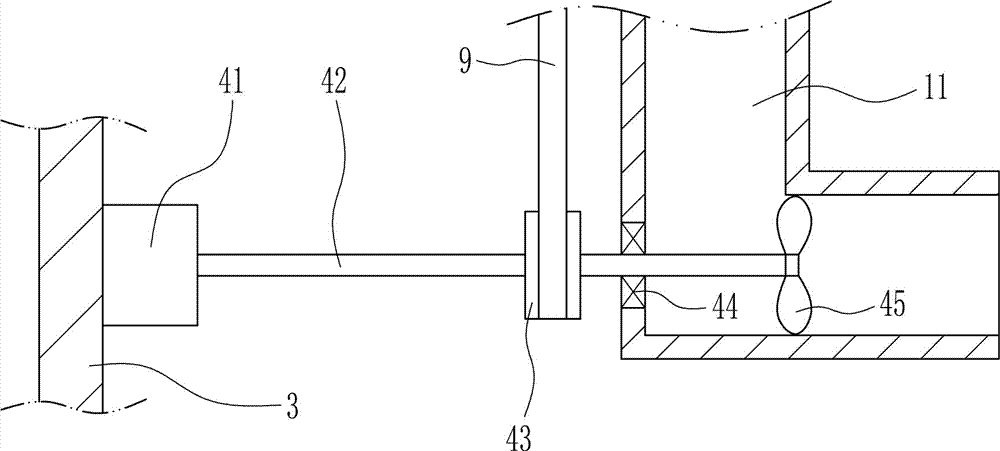

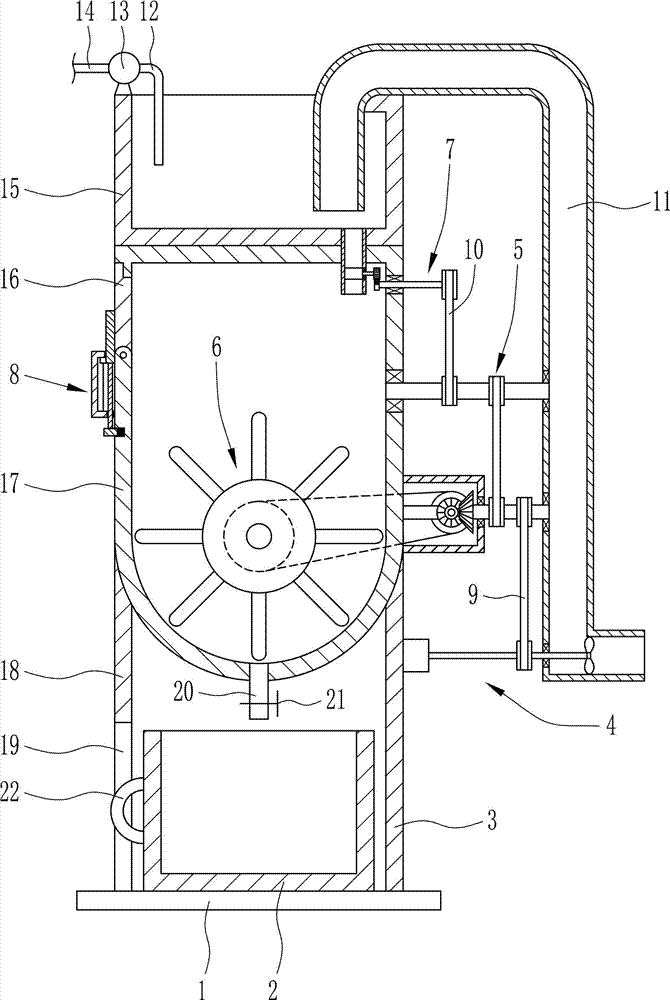

[0038] An energy-saving and environment-friendly desulfurizer for a thermal power plant, such as Figure 1-8 As shown, it includes a first mounting plate 1, a collection box 2, a second mounting plate 3, a smoking mechanism 4, a linkage mechanism 5, an agitating mechanism 6, an adjusting mechanism 7, a fixing mechanism 8, a first flat belt 9, a second flat belt Belt 10, smoking pipe 11, water pipe 12, water pump 13, water pipe 14, water tank 15, first baffle 16, reaction box 17, third mounting plate 18, first water outlet pipe 20, valve 21, first handle 22 , the second handle 24 and the shutter 25; the second mounting plate 3 and the third mounting plate 18 are sequentially fixed on the top of the first mounting plate 1 along the length direction of the first mounting plate 1; the collection box 2 is placed on the first mounting plate 1 The top is located between the second mounting plate 3 and the third mounting plate 18; the third mounting plate 18 is provided with a first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com