Efficient multicolor spraying production device for bottle lids

A technology for production equipment and bottle caps, applied in the direction of spraying equipment, equipment for coating liquid on the surface, coating, etc., can solve problems such as difficulty in attracting customers' eyes, lack of bright spots in appearance, lack of production equipment, etc., to reduce energy consumption , ensuring reliability and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

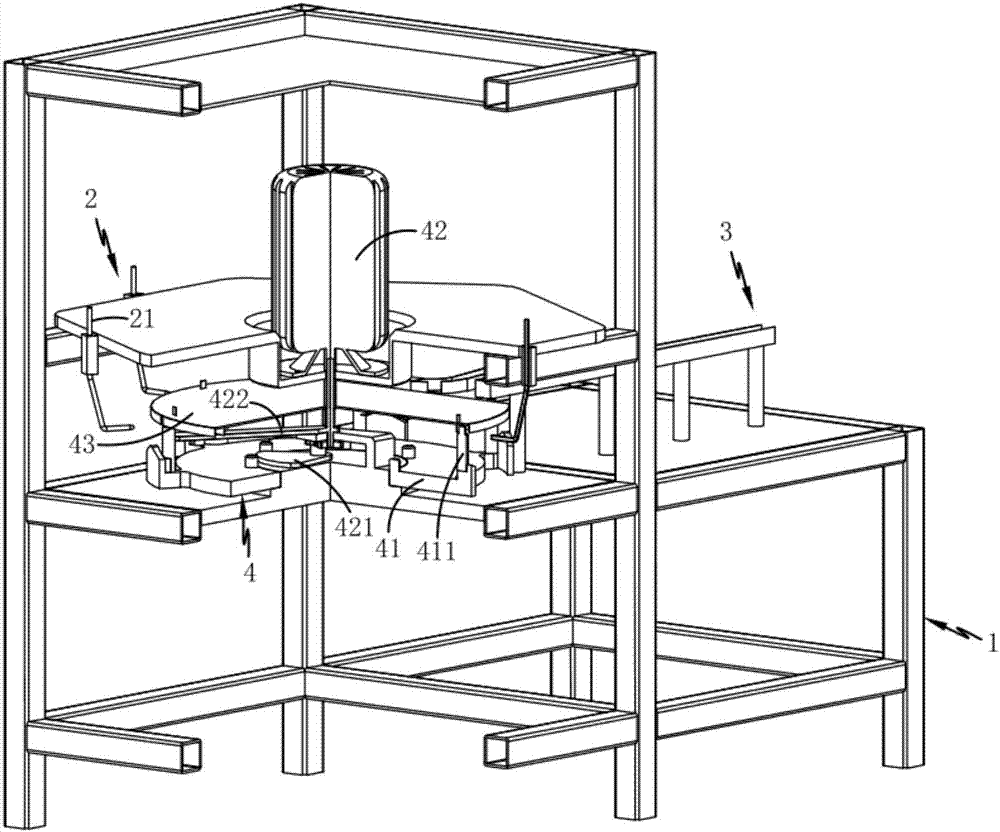

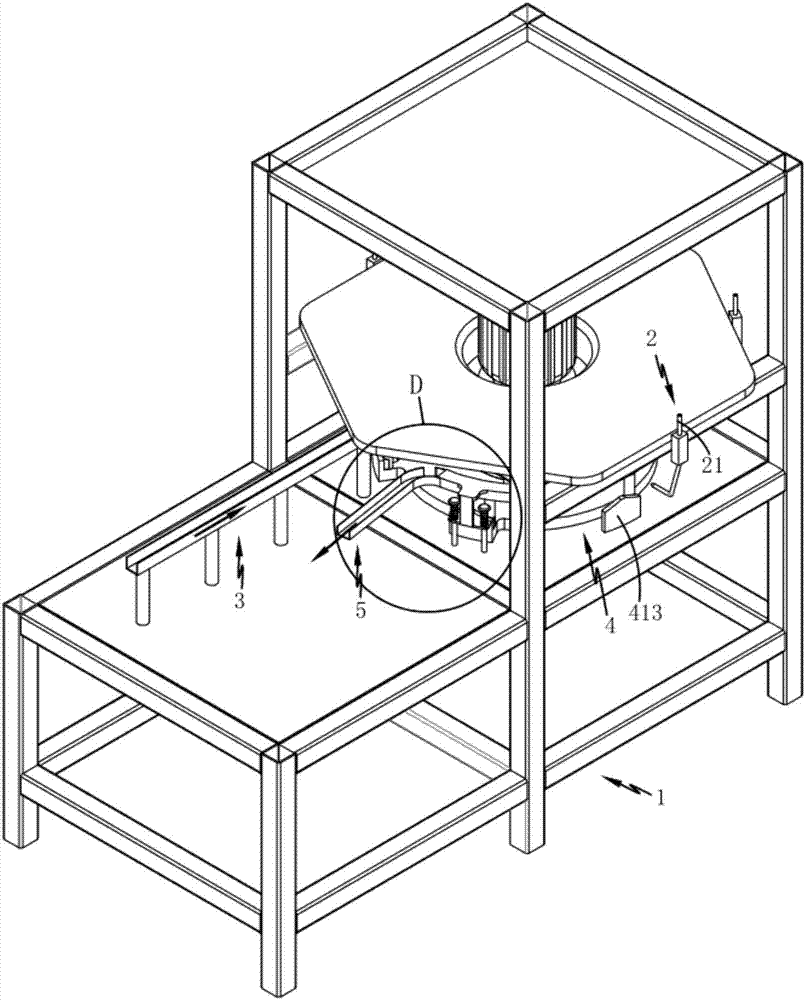

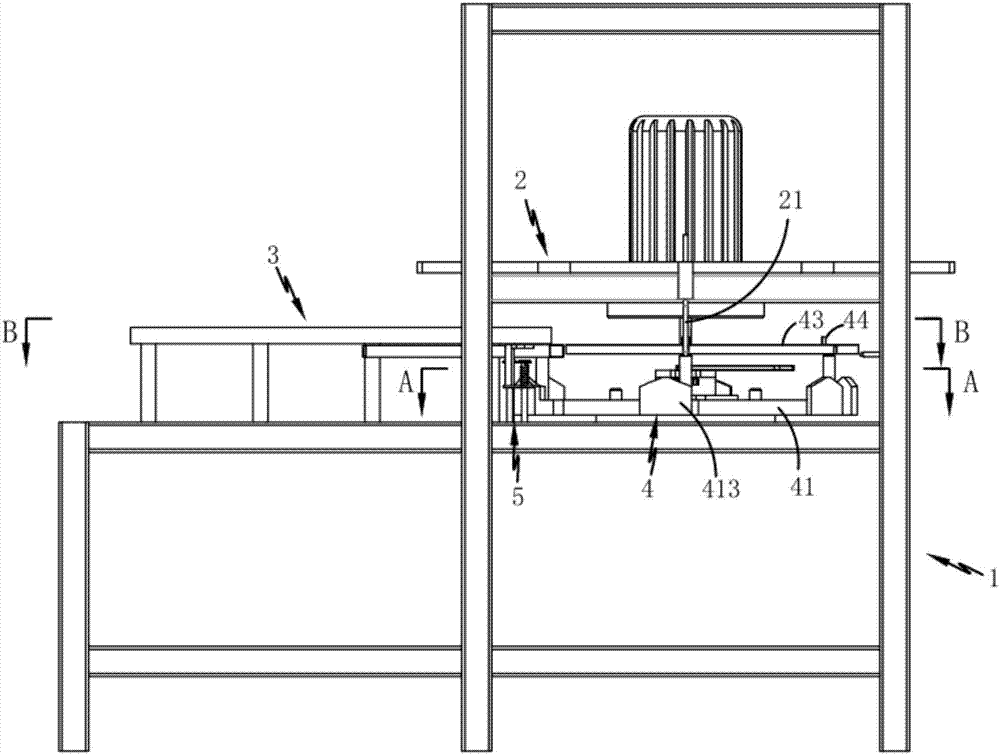

[0044] Such as figure 1 , 2 , 3 and 4, a bottle cap high-efficiency multi-color spraying production device includes a frame 1 and a spraying mechanism 2 installed on the frame 1 for bottle cap spraying, and also includes:

[0045] A feeding mechanism 3, the feeding mechanism 3 is installed on the frame 1, and several bottle caps are introduced one by one through the feeding mechanism 3;

[0046] The station conversion mechanism 4, after the bottle cap introduced by the feeding mechanism 3 is driven by the station conversion mec...

Embodiment 2

[0051] Such as Figure 6 , 7 and 8, wherein the same or corresponding parts with the first embodiment adopt the corresponding reference numerals with the first embodiment, and for the sake of simplicity, only the difference from the first embodiment is described below; the second embodiment is different from the first embodiment The difference is that the feeding mechanism 3 includes a transmission channel 31 for sequentially transporting bottle caps, a blanking opening 32 arranged at the end of the transmission channel 31, and a blanking plate for controlling the opening and closing of the blanking opening 32 33, the blanking plate 33 is driven by the second driving part 422 to realize the discontinuous opening of the blanking opening 32; wherein the blanking plate 33 is rotated and arranged at the bottom of the blanking opening 32, and it has elastic restoring force, and the normal state is In the state of closing the blanking port 32, the second driving part 422 pushes the...

Embodiment 3

[0054] Such as figure 2 , 9 , 10 and 11, wherein the same or corresponding parts as in the second embodiment adopt the corresponding reference numerals with the second embodiment, for the sake of simplicity, only the differences from the second embodiment are described below; the third embodiment is similar to the second embodiment The difference of Example 2 is that the output mechanism 5 includes a guide rod 51, a peeling assembly 52 that is sleeved on the guide rod 51 to peel off the bottle cap in a reciprocating manner, and is sleeved on the guide rod 51 in a compressed state. The compression spring 53 arranged on and in contact with the stripping assembly 52; the top of the jacking boss 413 arranged on the outer ring of the positioning assembly 411 is arranged in a triangle, and the turntable assembly 41 synchronously drives the jacking boss 413 to rotate during the rotation process. , during the rotation, the bottle cap sleeved on the positioning assembly 411 is peeled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com