Epoxy mortar for rapid repair in low-temperature environment and preparation method thereof

A technology of epoxy mortar and preparation method, which is applied in the field of building materials, can solve problems such as slow curing, inability to achieve high strength and fast solidification, and inability to quickly repair structures, so as to achieve the effect of reducing costs and high test strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

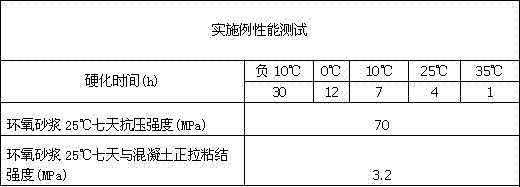

Examples

Embodiment

[0025] Example: An epoxy mortar made by mixing component A, component B and component C in a mass ratio of 3:1:10

[0026] in:

[0027] Described A component is made up of the following raw materials in parts by weight:

[0028] Bisphenol A type epoxy resin 100 parts

[0029] Glycidyl ether diluent 10 parts

[0030] Toughener 5 parts

[0031] 1 part coupling agent

[0032] Described B component is made up of the following raw materials in parts by weight:

[0033] Modified aliphatic polyamine curing agent 100 parts

[0034] Described C component consists of the following raw materials in parts by weight:

[0035] Quartz sand 100 parts

[0036] Fly ash 20 parts

[0037] Preparation method:

[0038] 1) Preparation of component A:

[0039] 1. Weighing Weigh each raw material in component A according to the above ratio,

[0040] 2. Mix Bisphenol A epoxy resin, glycidyl ether diluent, toughening agent, coupling agent, stir well

[0041] 3. Packaging

[0042] 2) Prepara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com