Steam assisted gravity drainage method

An auxiliary gravity and steam technology, which is applied in the field of oil drilling, can solve problems such as complex pressure control technology, high temperature of produced fluid, and complex lifting, and achieve the effects of lowering temperature, reducing drilling costs, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

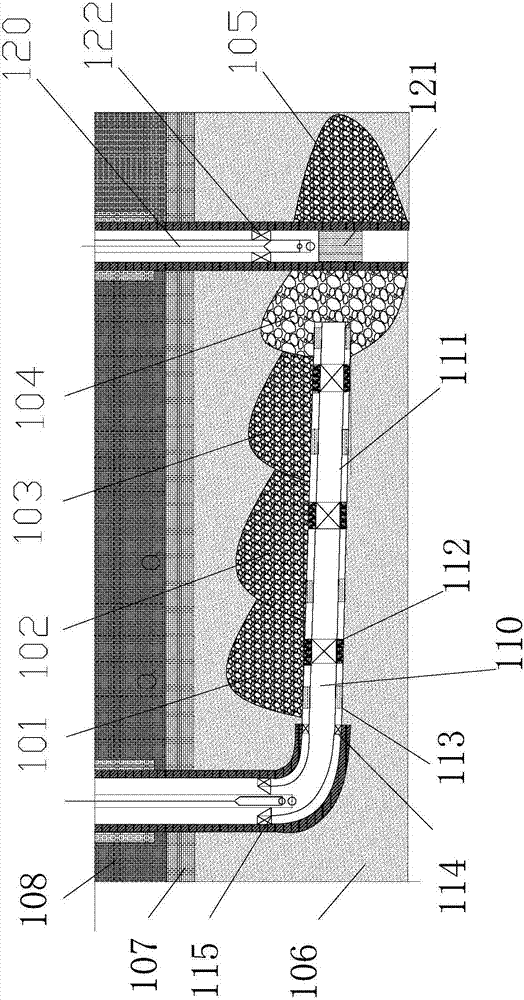

[0023] This application is based on the U-shaped well in the prior art, and is improved to obtain a new technical solution. figure 1 A schematic diagram of a U-shaped well set up according to the method of the present application is shown. Combine below figure 1 The method proposed in this application is introduced in detail. First step: setting the first well 110 and the second well 120 .

[0024] Wherein, the first well 110 is a horizontal well, and the second well 120 is a vertical well. The horizontal section of the first well 110 forms an included angle of 3-15 degrees with the horizontal direction, and a vertical well (ie, the second well) is drilled near the end of the horizontal section. The horizontal section of the horizontal well is located in the reservoir 106 , which is located below the surface 108 , caprock 107 . The horizontal section of the horizontal well includes a horizontal casing 111, which is divided into multiple sections by packers 112, and scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com