Improved roller cooling equipment

An improved drum cooling technology, which is applied to lighting and heating equipment, furnace types, and discharged materials. It can solve the problems of poor cooling effect of single drum, large temperature difference of materials, uneven cooling, etc., and achieve rapid cooling. , Good cooling effect, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

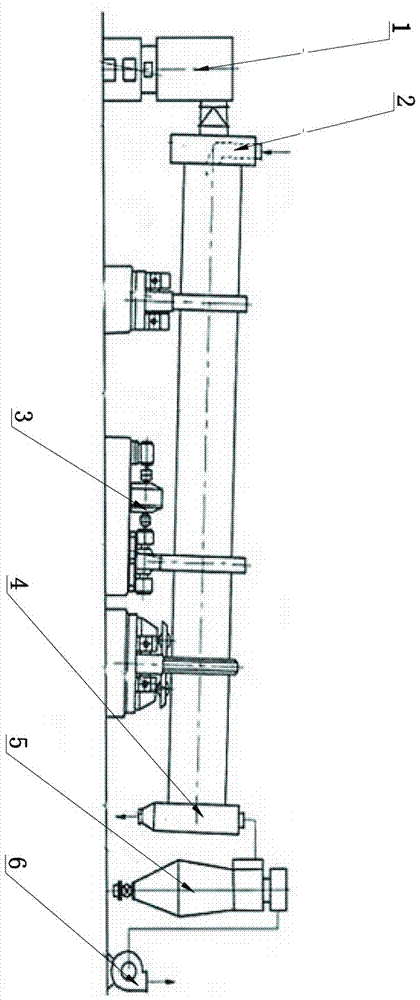

[0013] Such as figure 1 As shown, the purpose of the present invention is achieved in this way: an improved drum cooling device, including a drum body, the drum body is set to a circle, and the front end, middle end and rear end of the drum body are respectively provided with annular tracks , one side of the drum is provided with an inlet, the other side of the drum is provided with an outlet, the inlet is arranged above, the outlet is arranged below, the roller is arranged obliquely, and the position of the inlet is high At the height of the exit, the entrance is provided with a support device 1, the support device 1 is fixed on the ground, the rear end is provided with a rear end support, and the rear end support is arranged in conjunction with the ring track provided at the rear end, A driving device 3 is arranged under the middle end in conjunction with a circular track, and a dust removal device 5 is arranged at the outlet, and the dust removal device 5 is arranged in con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com