Prepressing amount measurement device for producing motors of cement cutting equipment

A technology for cutting equipment and quantity measurement, which is applied in the direction of mechanical measuring devices, measuring devices, and mechanical devices, etc. It can solve the problems of inaccurate detection results, manual pressing of the rotating shaft, and poor test results, so as to achieve accurate detection results and improve work efficiency. Efficiency, reduced workload and labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

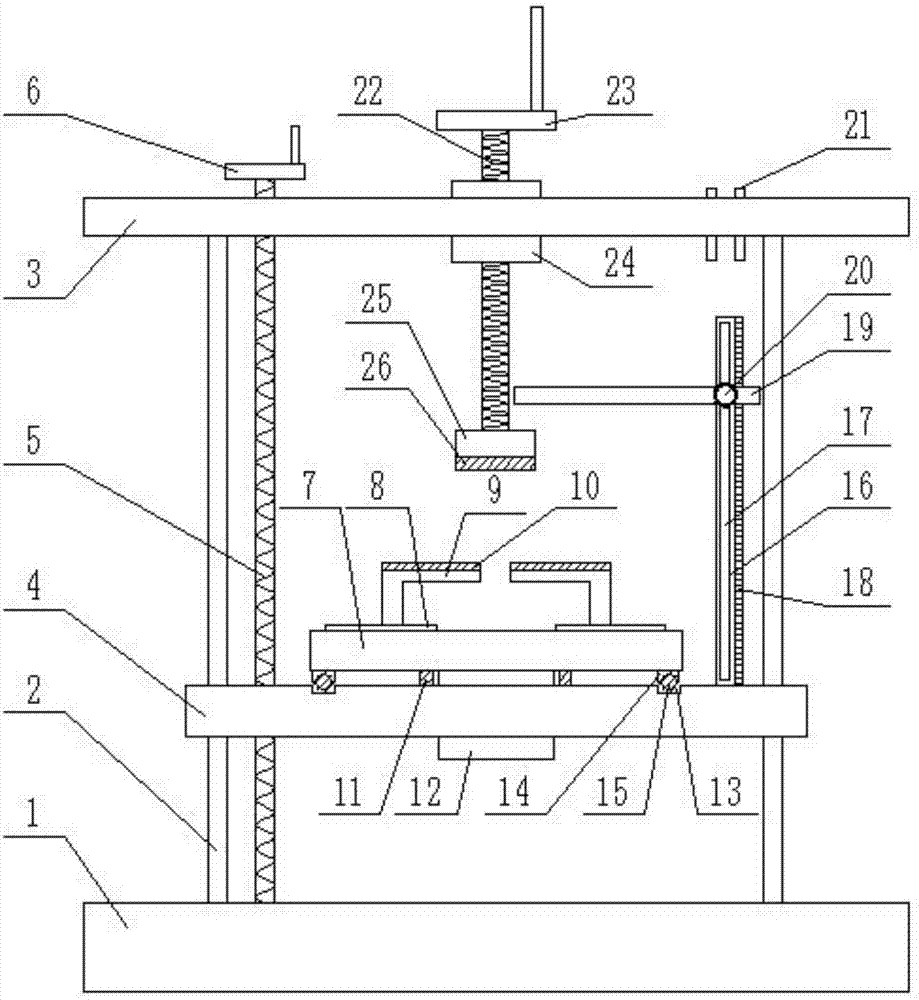

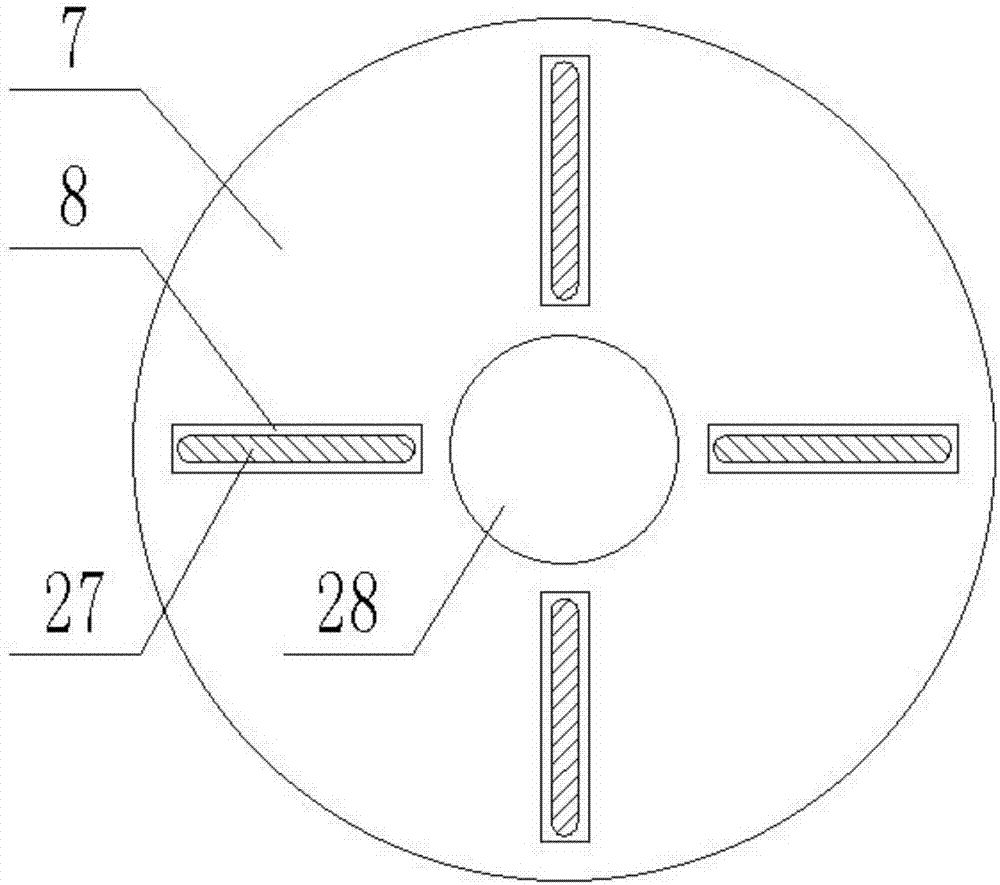

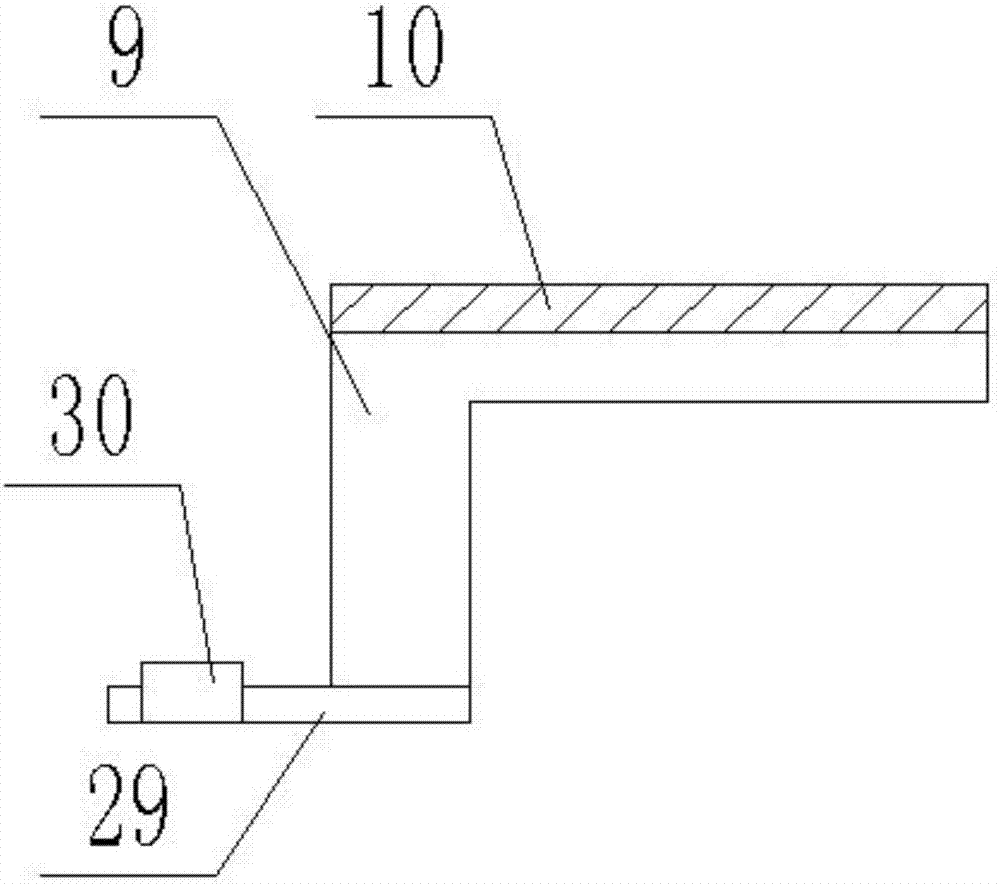

[0020] see Figure 1-3 , a kind of preload measuring device for cement cutting equipment motor production, including a device body, the device body is provided with a base 1, a support column 2 is provided above the base 1, and the support column 2 and the base 1 are welded The top of the support column 2 is fixedly connected with a beam 3, and the beam 3 and the base 1 are fixedly connected by welding. The device body is provided with a support plate 4, and the two ends of the support plate 4 are covered Connected to the supporting column 2 and slidingly connected with the supporting column 2, the inner side of the left supporting column 2 is provided with a first screw 5, and the first screw 5 is connected to the supporting plate 4 through a screw type connection. A through hole is set on the crossbeam 3, and the rocking wheel A6 passes through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com