Optical path gating mechanism

An optical path and iron core technology, applied in the field of optical path gating mechanism, can solve the problems of large power supply current and heat generation of electromagnets, and achieve the effect of small driving current and low power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in more detail below with reference to the drawings and examples, so as to better understand the solution of the present invention and its advantages in various aspects. However, the specific embodiments and examples described below are for the purpose of illustration only, rather than limiting the present invention.

[0025] The "connection" mentioned in the present invention should be interpreted in a broad sense unless otherwise specified or limited, and may be a direct connection or a connection through an intermediary.

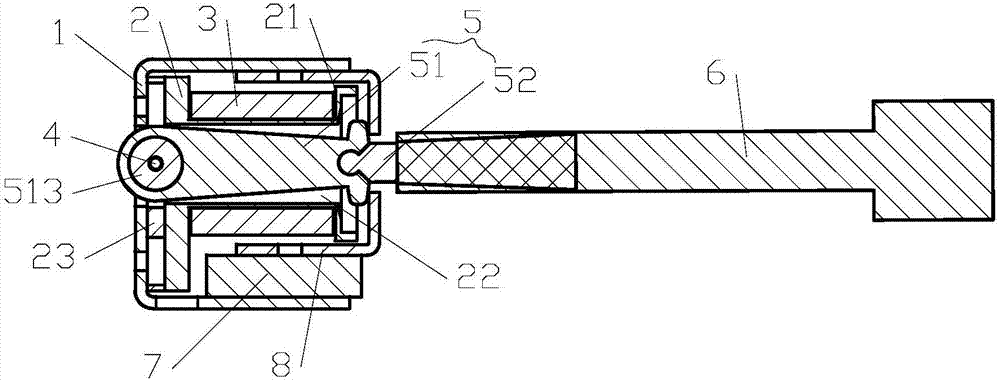

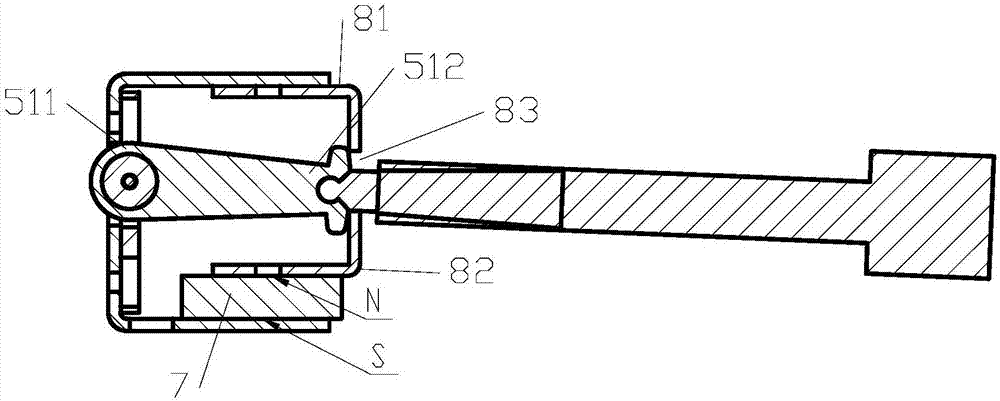

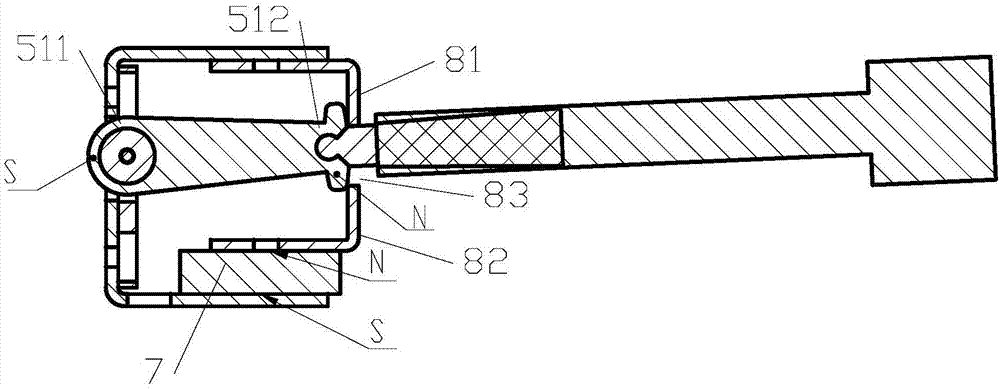

[0026] Such as figure 1 , figure 2 and image 3 As shown, the present invention provides an optical path gating mechanism, including: a housing 1 , a coil frame 2 , a coil 3 , a rotating shaft 4 , a swing arm 5 , a light blocking plate 6 , a permanent magnet 7 and a limiting plate 8 . Utilizing the cooperation of the permanent magnet and the electromagnet, the swing arm of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com