Milk powder brewing device for paediatric department

A technology for milk powder and pediatrics, which is applied to mixers with rotating stirring devices, transportation, packaging, dissolution, etc., which can solve the problems of time-consuming and laborious, inability to control the amount of milk powder, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

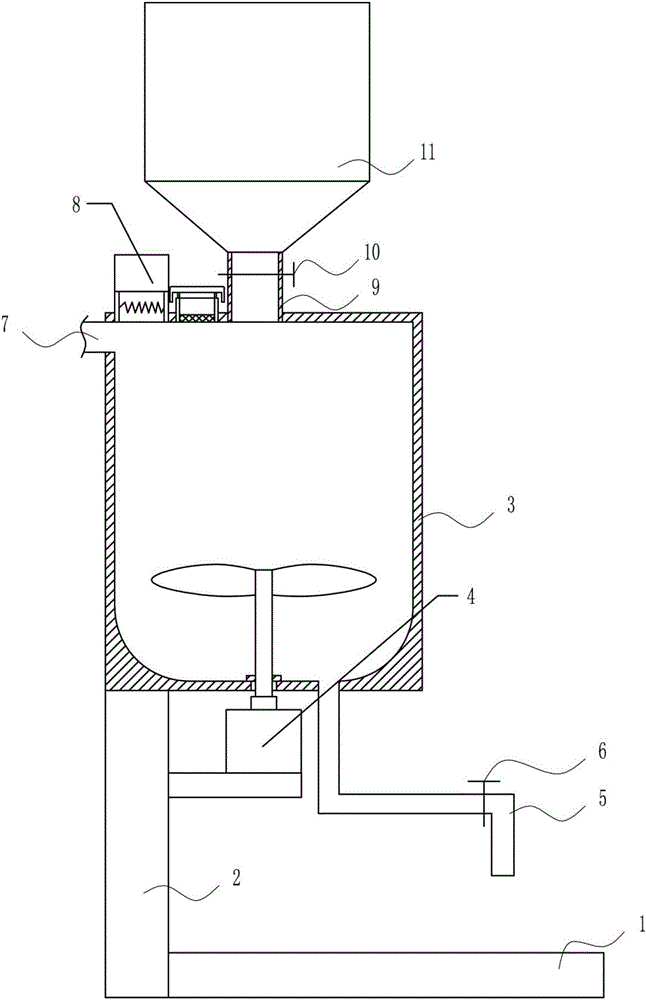

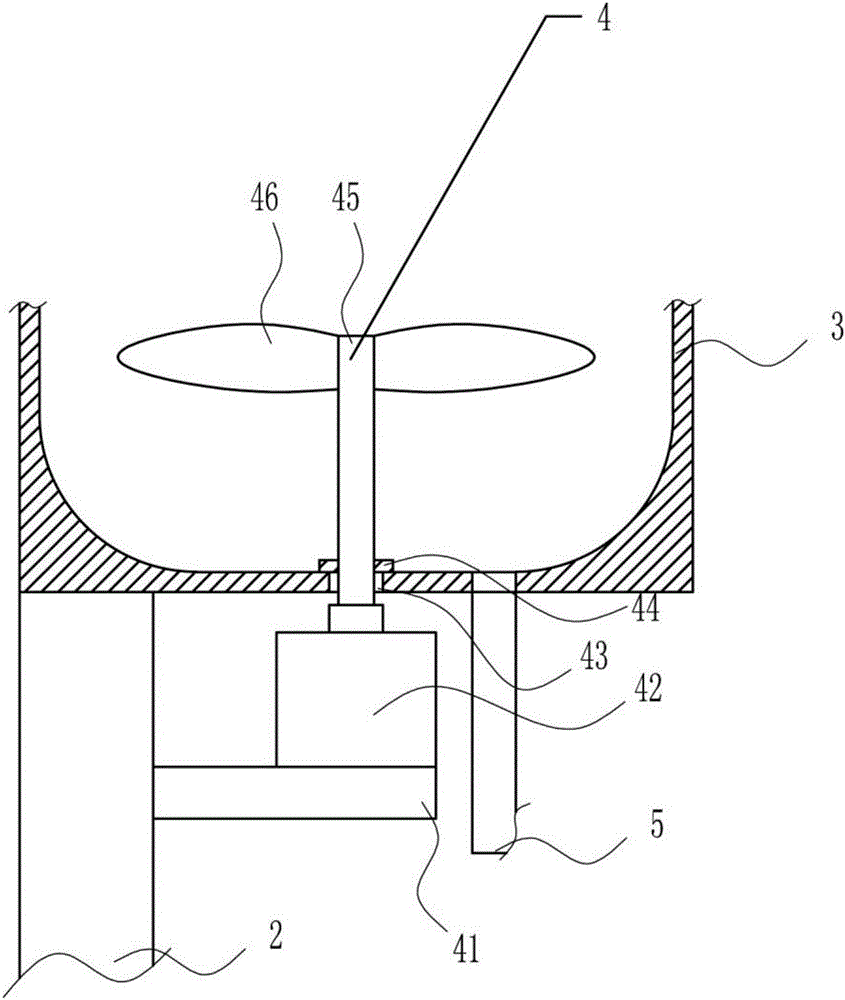

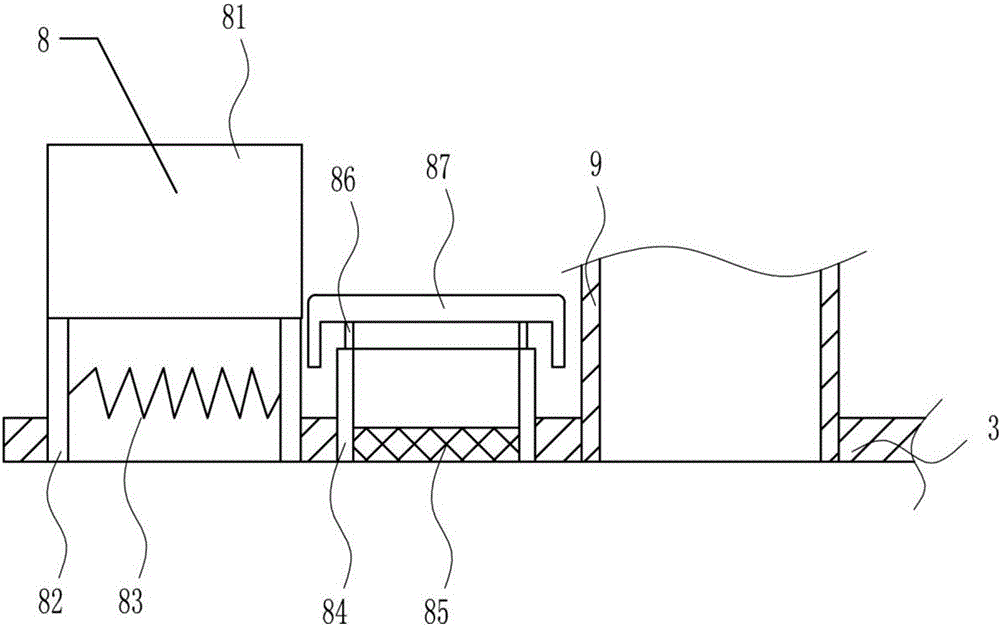

[0037] A device for making milk powder for children, such as Figure 1-7 As shown, it includes a bottom plate 1, a support plate 2, a stirring bottle 3, a stirring device 4, a powder outlet pipe 5, a first valve 6, a first water inlet pipe 7, an air drying device 8, a powder inlet pipe 9, a second valve 10 and Funnel 11, a support plate 2 is installed on the left side of the bottom plate 1, a stirring bottle 3 is installed on the top of the support plate 2, a powder outlet pipe 5 is connected to the right side of the bottom of the stirring bottle 3, and the powder outlet pipe 5 communicates with the inside of the stirring bottle 3, and the powder outlet The tail end of the pipe 5 is located above the bottom plate 1, the powder outlet pipe 5 is provided with a first valve 6, the upper left side of the stirring bottle 3 is connected with a first water inlet pipe 7, the first water inlet pipe 7 communicates with the inside of the stirring bottle 3, and the stirring bottle 3 The p...

Embodiment 2

[0039] A device for making milk powder for children, such as Figure 1-7 As shown, it includes a bottom plate 1, a support plate 2, a stirring bottle 3, a stirring device 4, a powder outlet pipe 5, a first valve 6, a first water inlet pipe 7, an air drying device 8, a powder inlet pipe 9, a second valve 10 and Funnel 11, a support plate 2 is installed on the left side of the bottom plate 1, a stirring bottle 3 is installed on the top of the support plate 2, a powder outlet pipe 5 is connected to the right side of the bottom of the stirring bottle 3, and the powder outlet pipe 5 communicates with the inside of the stirring bottle 3, and the powder outlet The tail end of the pipe 5 is located above the bottom plate 1, the powder outlet pipe 5 is provided with a first valve 6, the upper left side of the stirring bottle 3 is connected with a first water inlet pipe 7, the first water inlet pipe 7 communicates with the inside of the stirring bottle 3, and the stirring bottle 3 The p...

Embodiment 3

[0042] A device for making milk powder for children, such as Figure 1-7 As shown, it includes a bottom plate 1, a support plate 2, a stirring bottle 3, a stirring device 4, a powder outlet pipe 5, a first valve 6, a first water inlet pipe 7, an air drying device 8, a powder inlet pipe 9, a second valve 10 and Funnel 11, a support plate 2 is installed on the left side of the bottom plate 1, a stirring bottle 3 is installed on the top of the support plate 2, a powder outlet pipe 5 is connected to the right side of the bottom of the stirring bottle 3, and the powder outlet pipe 5 communicates with the inside of the stirring bottle 3, and the powder outlet The tail end of the pipe 5 is located above the bottom plate 1, the powder outlet pipe 5 is provided with a first valve 6, the upper left side of the stirring bottle 3 is connected with a first water inlet pipe 7, the first water inlet pipe 7 communicates with the inside of the stirring bottle 3, and the stirring bottle 3 The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com